Progressive vacuum constant temperature biogas generator

A biogas generator, a progressive technology, is applied in the directions of gas production bioreactors, biochemical instruments, biochemical equipment and methods, etc., to achieve the effects of high efficiency, favorable for popularization and application, and efficient gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

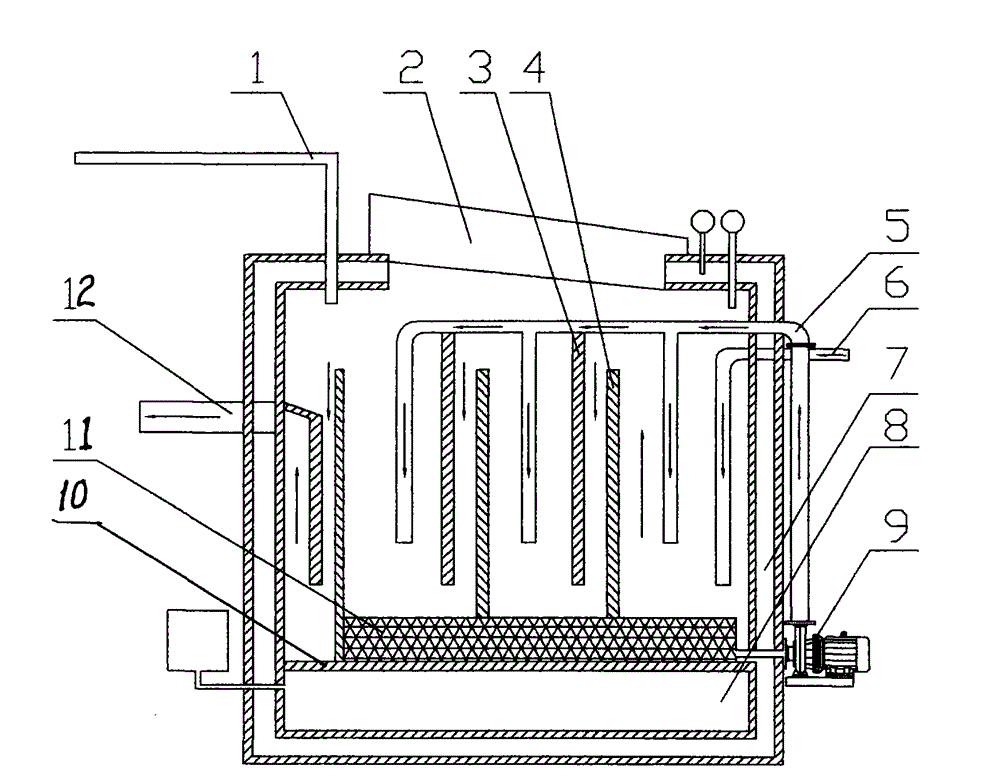

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] like figure 1 As shown, the progressive vacuum constant temperature biogas generator includes a gas delivery port 1, a discharge port 12, a heating device 8, a progressive feeding mechanism, a solar heating device 2 and a housing 7, wherein the gas delivery port 1 is located above the housing 7 , The discharge port 12 is located on the housing, the heating device 8 is located in the heating chamber above the bottom of the housing and below the bottom plate 10, the solar heating device 2 is obliquely mounted on the top of the housing, and the progressive feeding mechanism is installed in the housing.

[0019] The progressive feeding mechanism includes a feeding pipe 6, an agitator 5, a stirring pump 9, a guide plate 3, a compartment plate 4 and a liquid collector 11, wherein the feeding pipe 6 passes through the upper side wall of the housing 7 and is inserted into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com