Air breaker

A breaker and air technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problems of low degree of air breakage, expensive equipment, low oxygenation efficiency, etc., to improve water treatment capacity , save energy and investment, and improve the effect of suction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

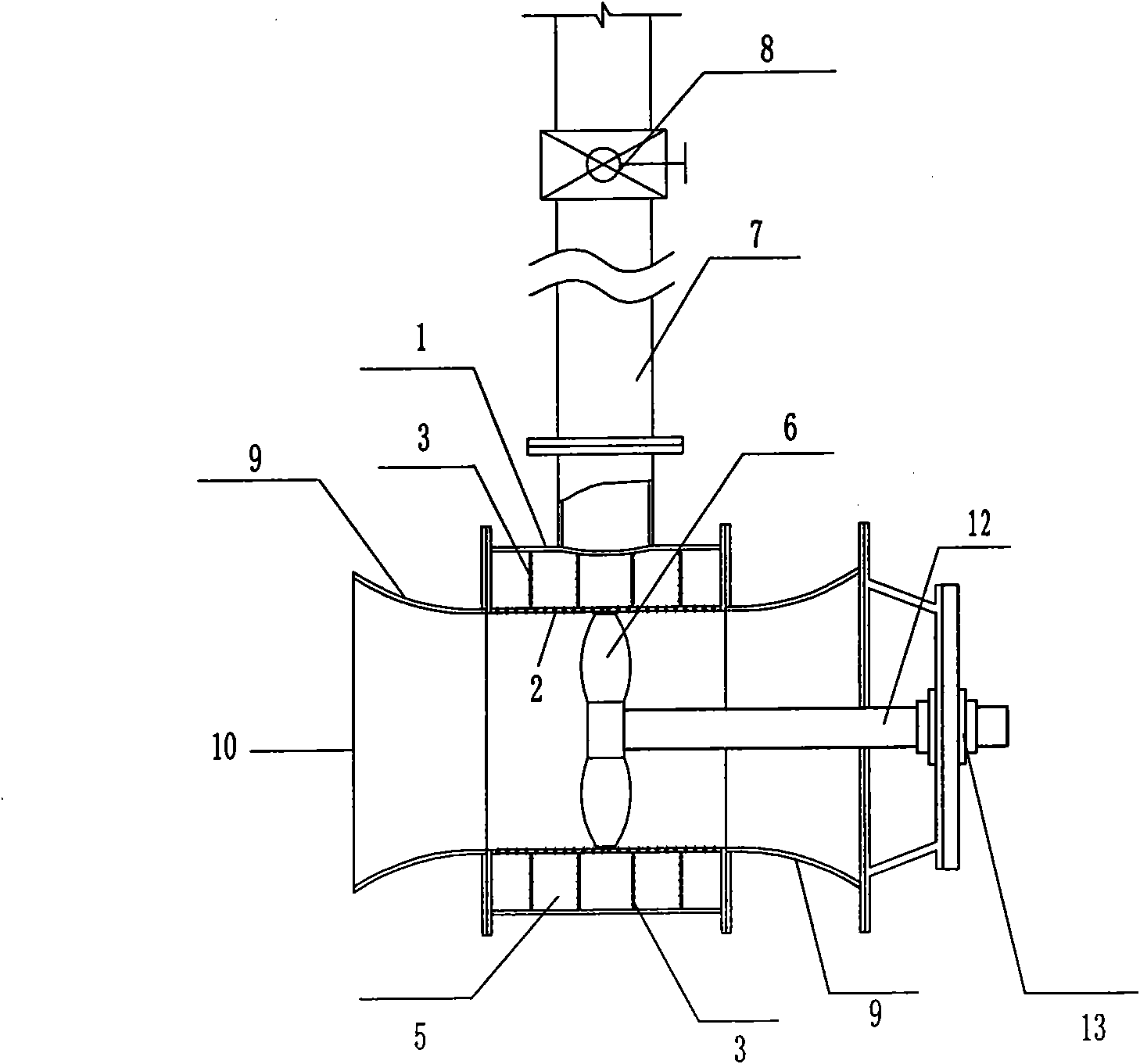

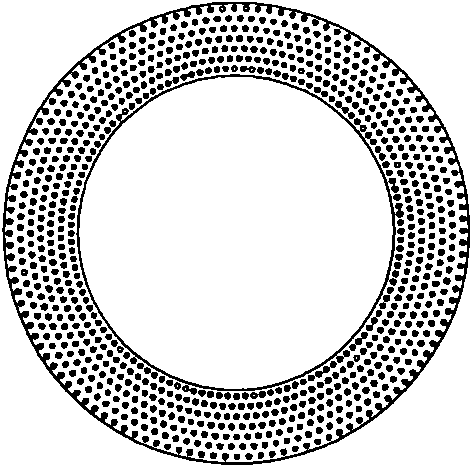

[0028] Air breaker (see structural diagram figure 1 ), comprising an air breaking cylinder with openings at both ends, a flow guiding cylinder 9, an air suction pipe 7, an air-breathing push-flow propeller 6 located inside the air breaking cylinder, and the air breaking cylinder is composed of an outer air collecting cylinder 1 and an innermost The dissolving mixing cylinder 2 of the first layer and the steel plates connecting the two cylinders together form an air collecting chamber 5, the wall of the dissolving mixing cylinder 2 is covered with round holes with diameters ranging from 2 to 60mm, and the air collecting chamber 5 is provided with 4 pieces and dissolving Mixing cylinder 2 is a disc type hollow porous broken piece 3 whose wall is vertical, see the schematic diagram figure 2 . The disc-type hollow porous fragment 3 is provided with round holes with a diameter ranging from 2 to 60 mm.

[0029] The air-breathing push-flow propeller 6 is composed of 4 propeller pa...

Embodiment 2

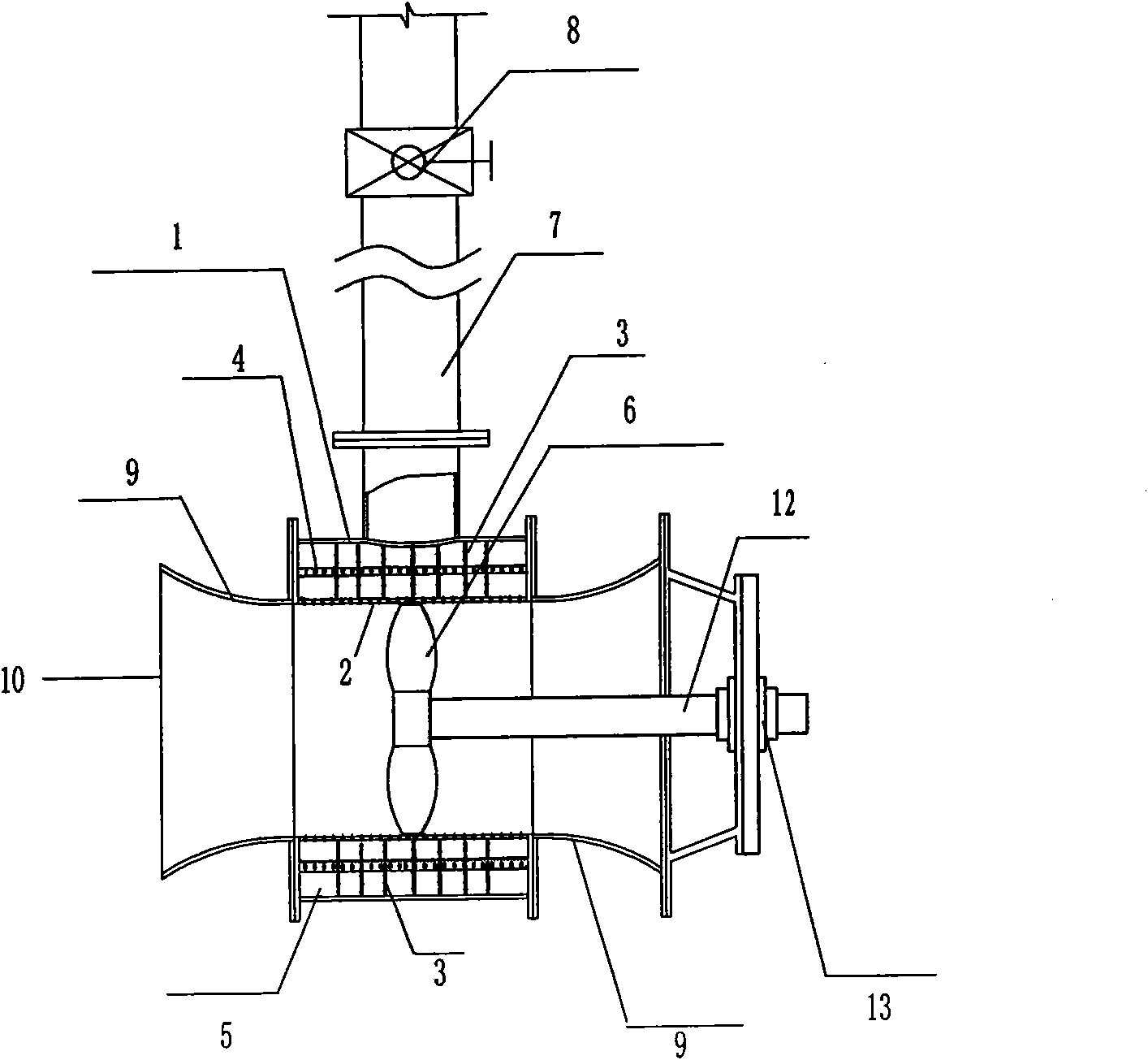

[0037] Air breaker (see structural diagram image 3 ), comprising an air breaking tube with openings at both ends, a guide tube 9, an air suction pipe 7, an air-breathing push-flow propeller 6 positioned inside the air breaking tube, and the air breaking tube is composed of an outer air collecting tube 1, and the most The dissolving mixing cylinder 2 in the inner layer and the steel plates connecting the two cylinders together form an air collecting chamber 5. The dissolving mixing cylinder 2 is covered with square holes with diameters ranging from 2 to 60 mm. The air collecting chamber 5 is provided with 7 pieces and The disc type hollow porous fragment 3 whose wall is vertical to the mixing cylinder 2 is dissolved. Parallel to the dissolving mixing cylinder 2, there is an annular porous crushing cylinder 4 which is equal in length and coaxial with the dissolving mixing cylinder 2 in the air collecting chamber 5 .

[0038] The walls of the disc-type hollow porous crushing pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com