Nail gun aerosol can and filling method thereof

An aerosol can and nail gun technology, applied in packaging, nailing tools, dispensing devices, etc., can solve the problems of difficult to reliably seal the inner bag and the output valve, high loss of pressurized propelling gas, easy leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

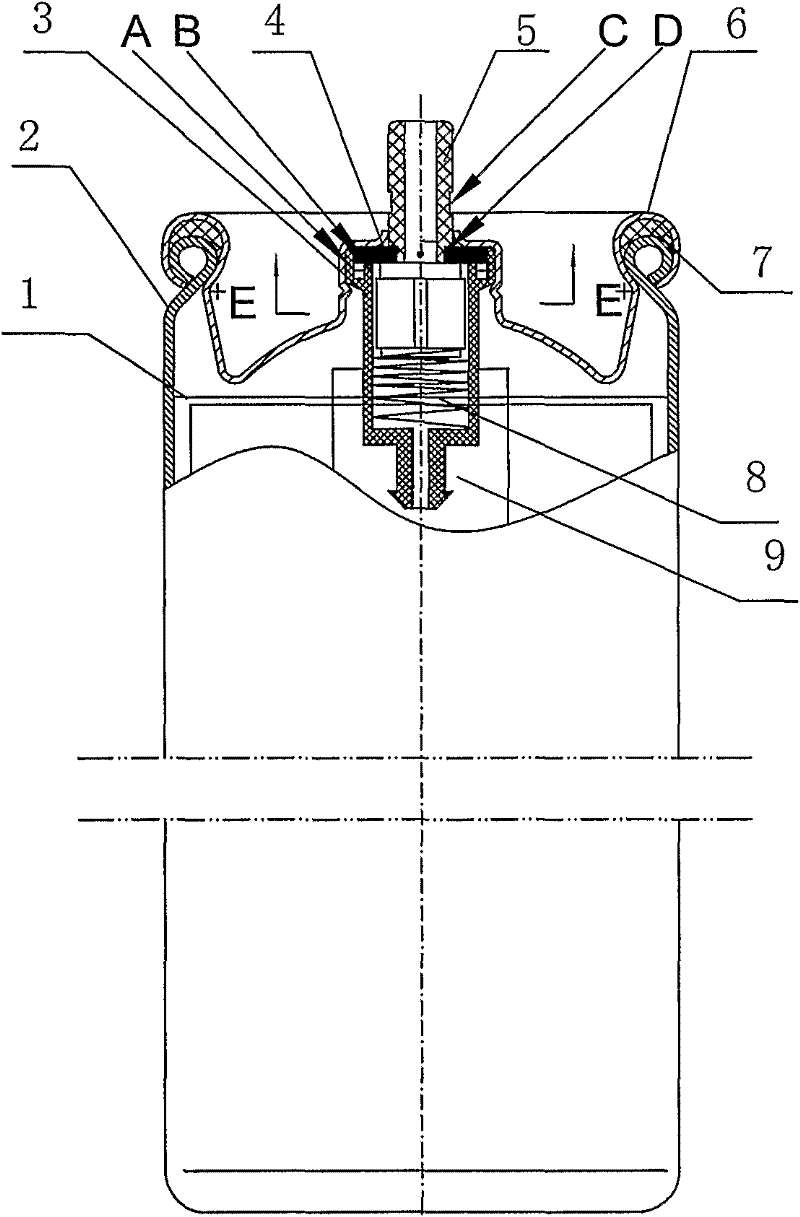

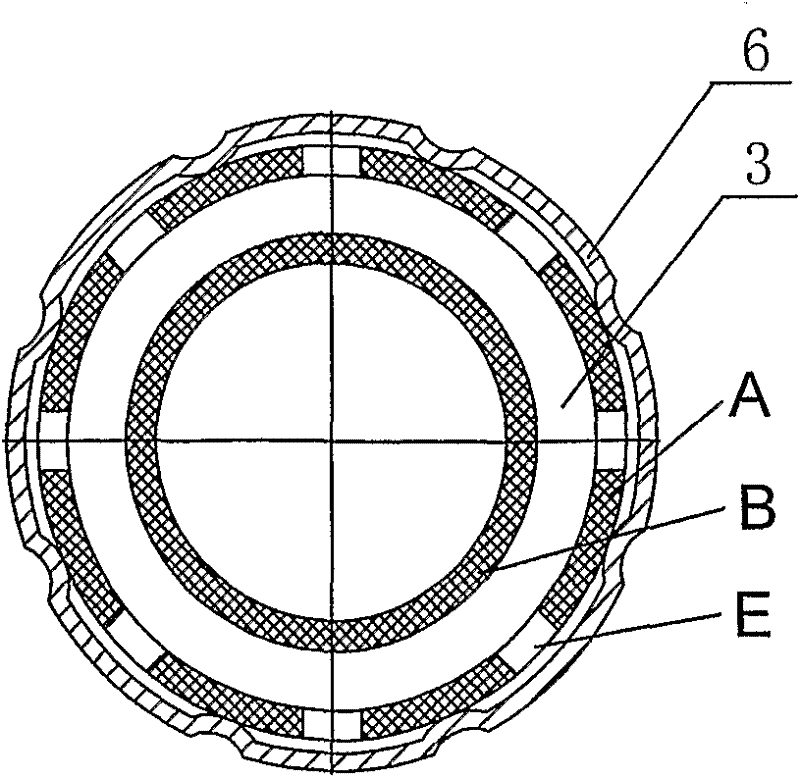

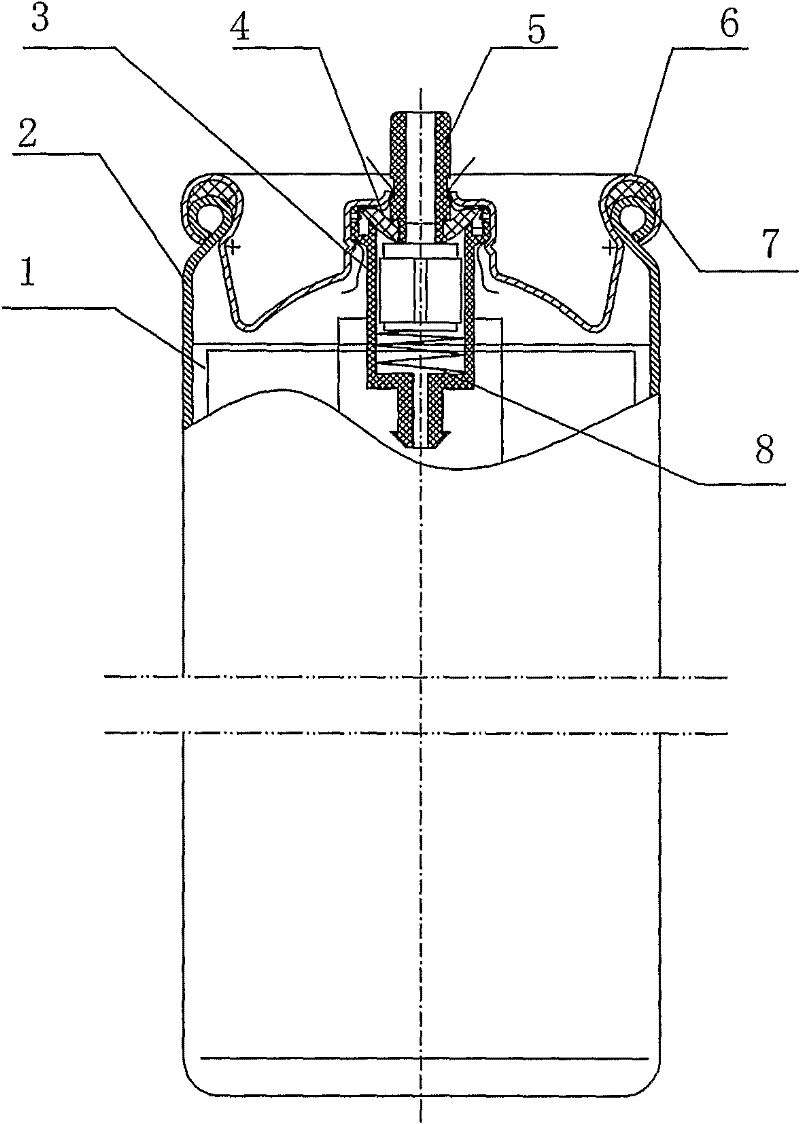

[0024] The nail gun aerosol can of the present embodiment is as figure 1 As shown, the tank body is composed of a tank cover 6 and a cylindrical tank cup 2 with flanged edges and a filling seal 7 snapped together. The middle part of the tank cover 6 extends outward to form a boss with a central opening. The opening in the center of the boss forms an outward seam, and the upper end of the fixed tubular valve body 3 is embedded in the boss, leaving an air gap between the two. The lower end of the valve body 3 is compressed and sealed with the lower part of the valve body, and the center is formed with an air outlet hole communicating with the inside of the inner bag 1, and the periphery is connected with the upper part of the inner bag 1 in the tank by hot-melt sealing. Installed in the valve body 3 is a valve core 5 that can be displaced up and down, thus having first, second and third axial positions. Elastic part 8 (spring) is housed between the lower end of spool 5 and valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com