Anti-off switch for elevator floor door

An elevator landing door and anti-detachment technology, which is applied in the direction of electric switches, circuits, electrical components, etc., can solve the problems of landing door device vibration, easy disengagement, elevator emergency stop, etc., to improve stability, facilitate implementation, and structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

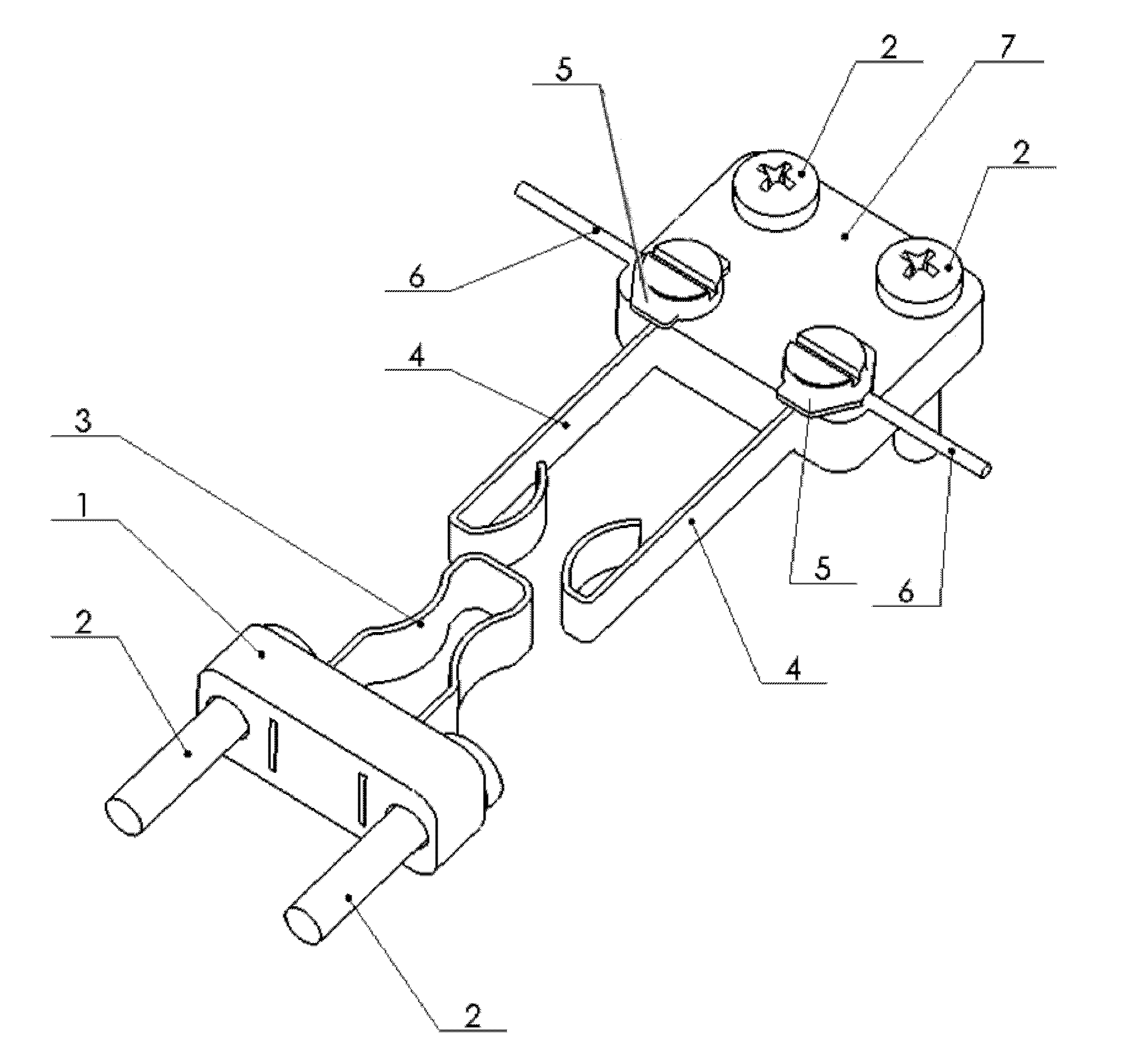

[0018] The present invention will be further described below with reference to the accompanying drawings.

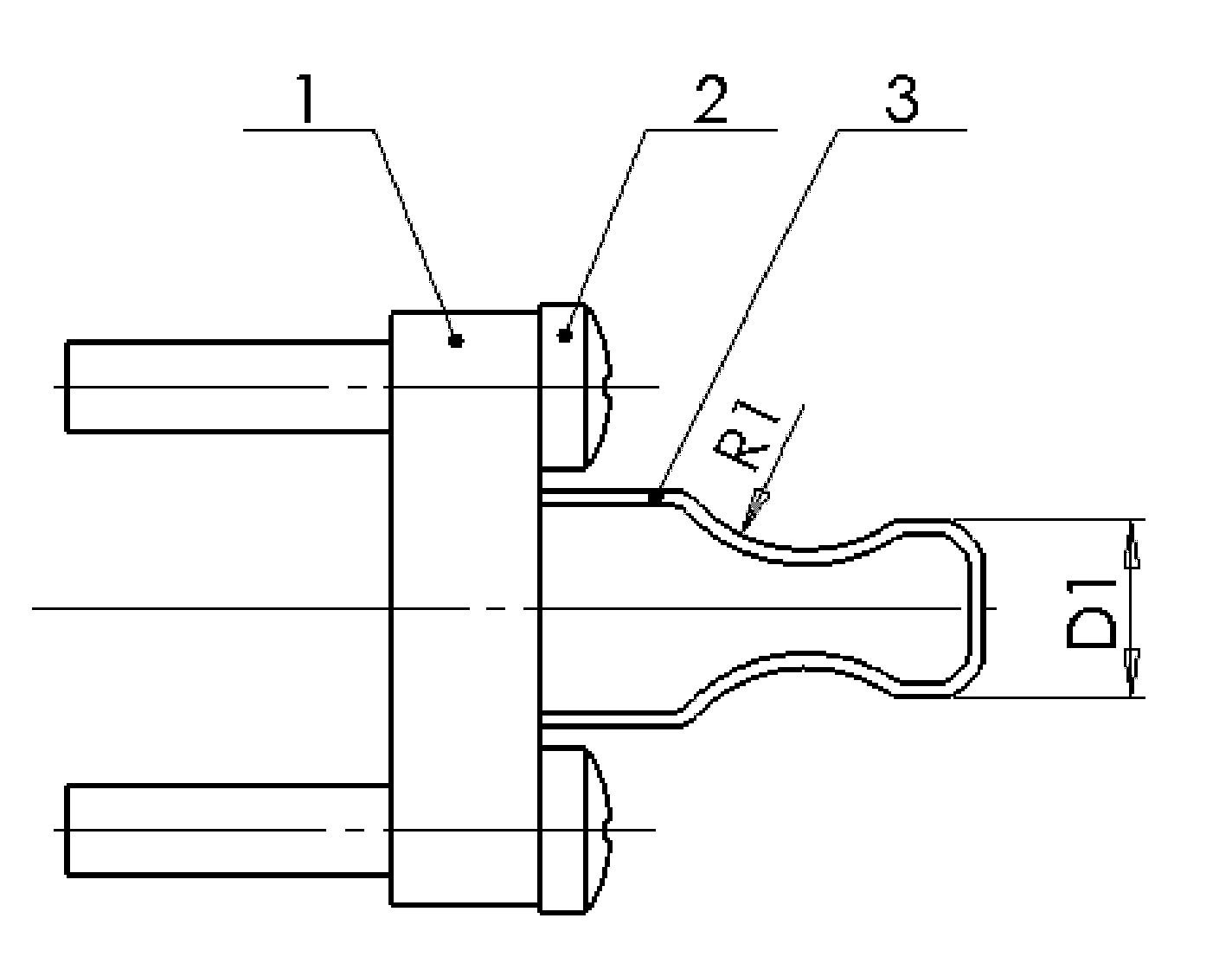

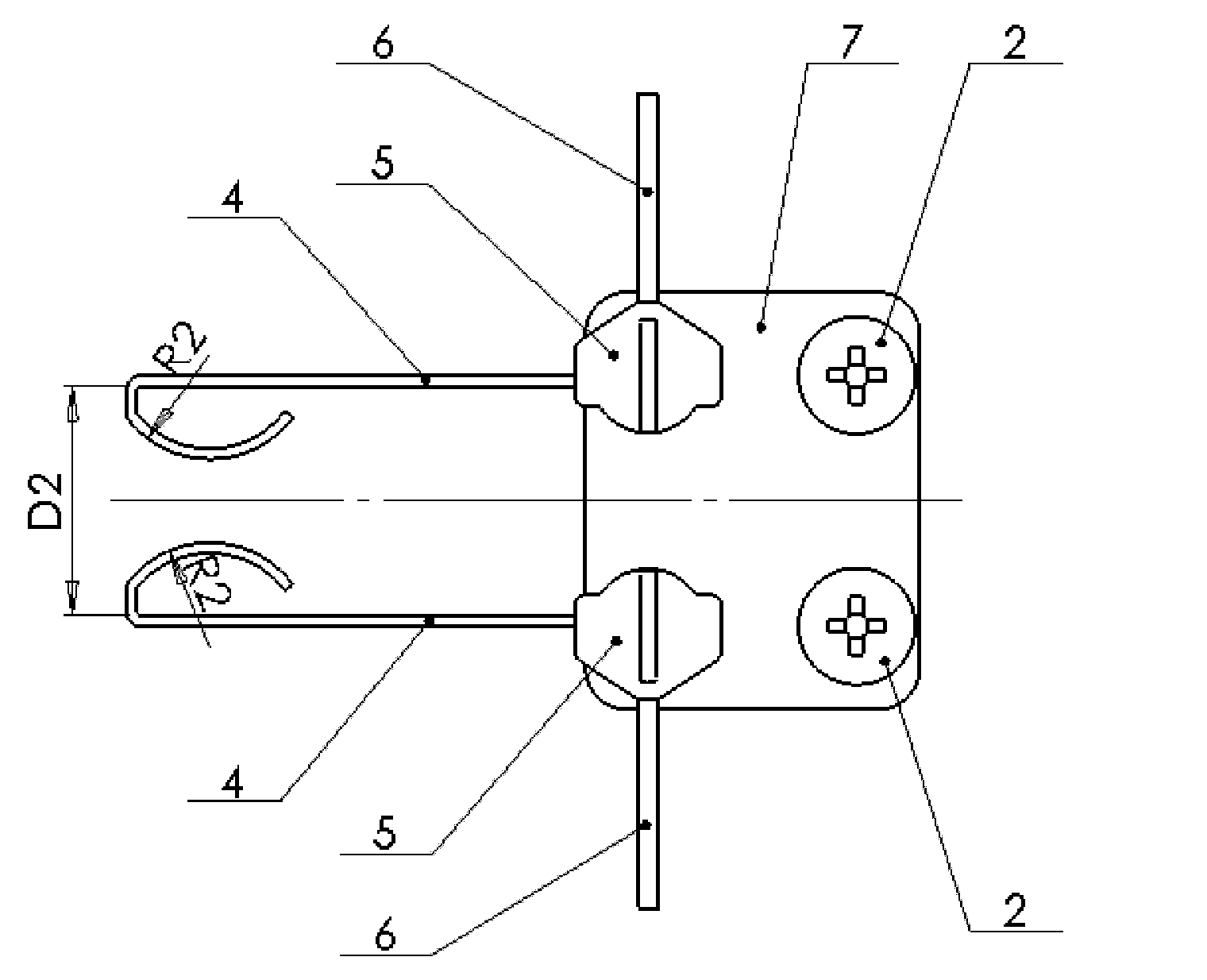

[0019] like Figure 1-Figure 3 As shown, an anti-off switch for an elevator landing door described in this embodiment includes a moving contact 3 arranged on a moving contact seat 1 and a static contact 4 arranged on a static contact seat 7. The static contact Fasteners and wire connectors 5 are provided on the head seat 7, fasteners are provided on the moving contact seat 1, and the moving contact 3 and the static contact 4 are respectively arranged on the moving contact seat 1 and the side wall of the static contact seat 7 and in an overhanging shape, the two can be plugged. Specifically, it can be realized by means of round pin cutting, overlapping of contact pieces, snap-fitting or embedding of male and female parts.

[0020] The moving contact 3 described in this embodiment is formed by symmetrical bending of a thin metal sheet, with a concave arc surface with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com