Catalytic combustion heat recovery system and method

A catalytic combustion and heat recovery technology, applied in lighting and heating equipment, dryers, drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

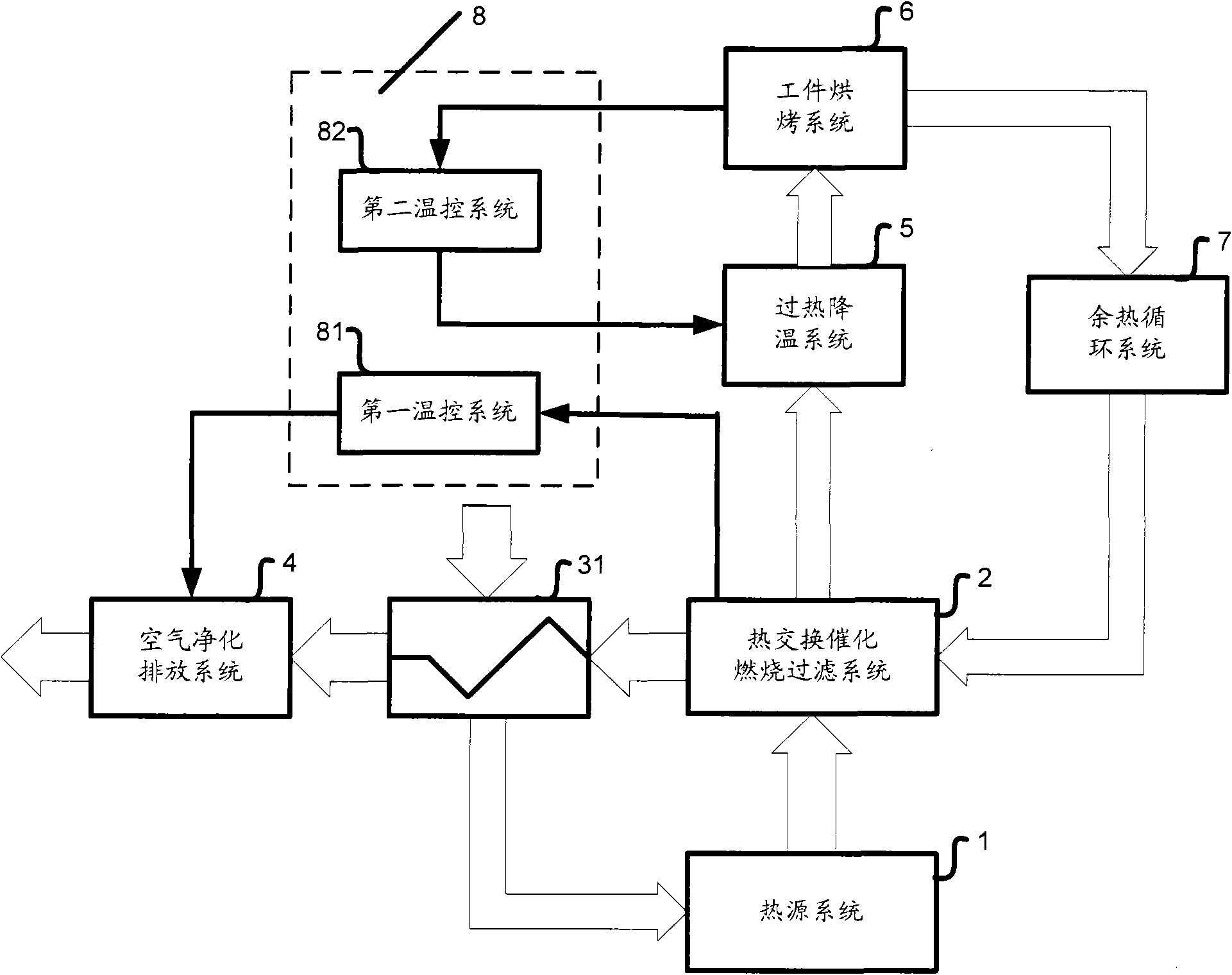

[0028] figure 1 A schematic structural diagram of a catalytic combustion heat recovery system according to the first embodiment of the present invention is shown. Specifically, in this embodiment, the catalytic combustion heat recovery system includes a heat source system 1, a heat exchange catalytic combustion filter system 2, a first heat exchange system 31, an air purification exhaust system 4, an overheating and cooling system 5, and a workpiece baking System 6, waste heat circulation system 7 and temperature control system 8. More specifically, in this embodiment, the catalytic combustion heat recovery system includes a first hot air circuit and a second hot air circuit, wherein the first hot air circuit is an open loop, which is mainly composed of the heat source system 1 , the heat exchange catalytic combustion filter system 2, the first heat exchange system 31 and the air purification discharge system 4 constitute; the second hot air circuit is a closed loop circuit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com