Flue gas dedusting energy-saving device for boiler

A technology for boiler flue gas and energy-saving devices, which is applied in the directions of climate sustainability, greenhouse gas reduction, and fixed duct components. temperature and other issues, to achieve the effect of easy maintenance and ash cleaning, saving boiler room space, and reducing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

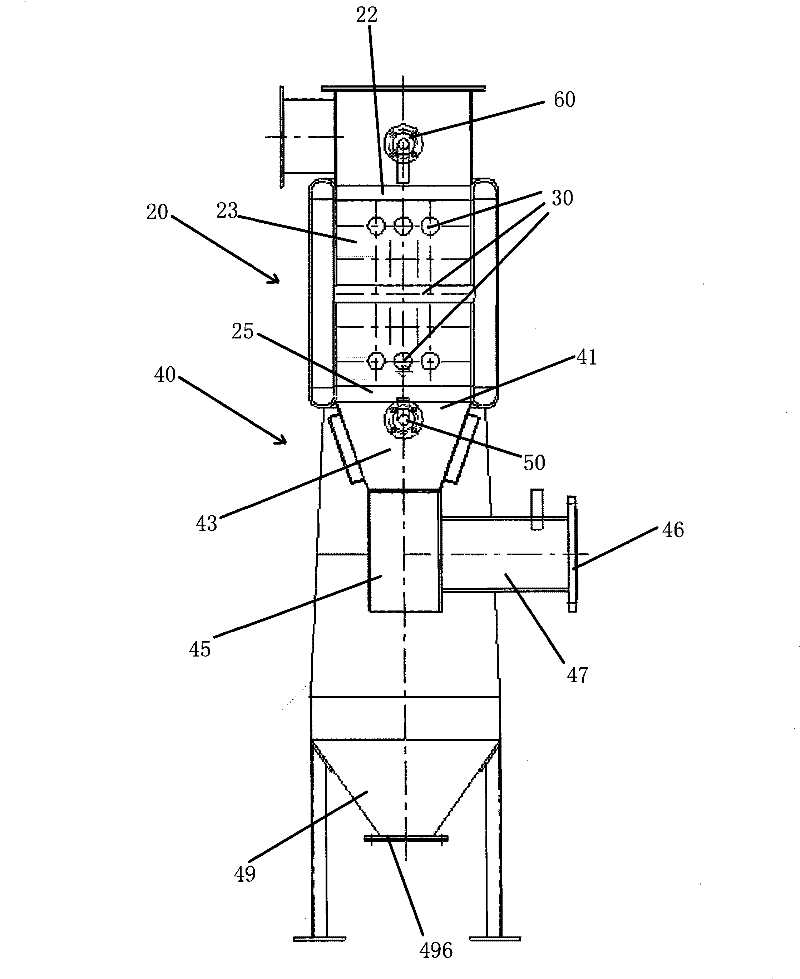

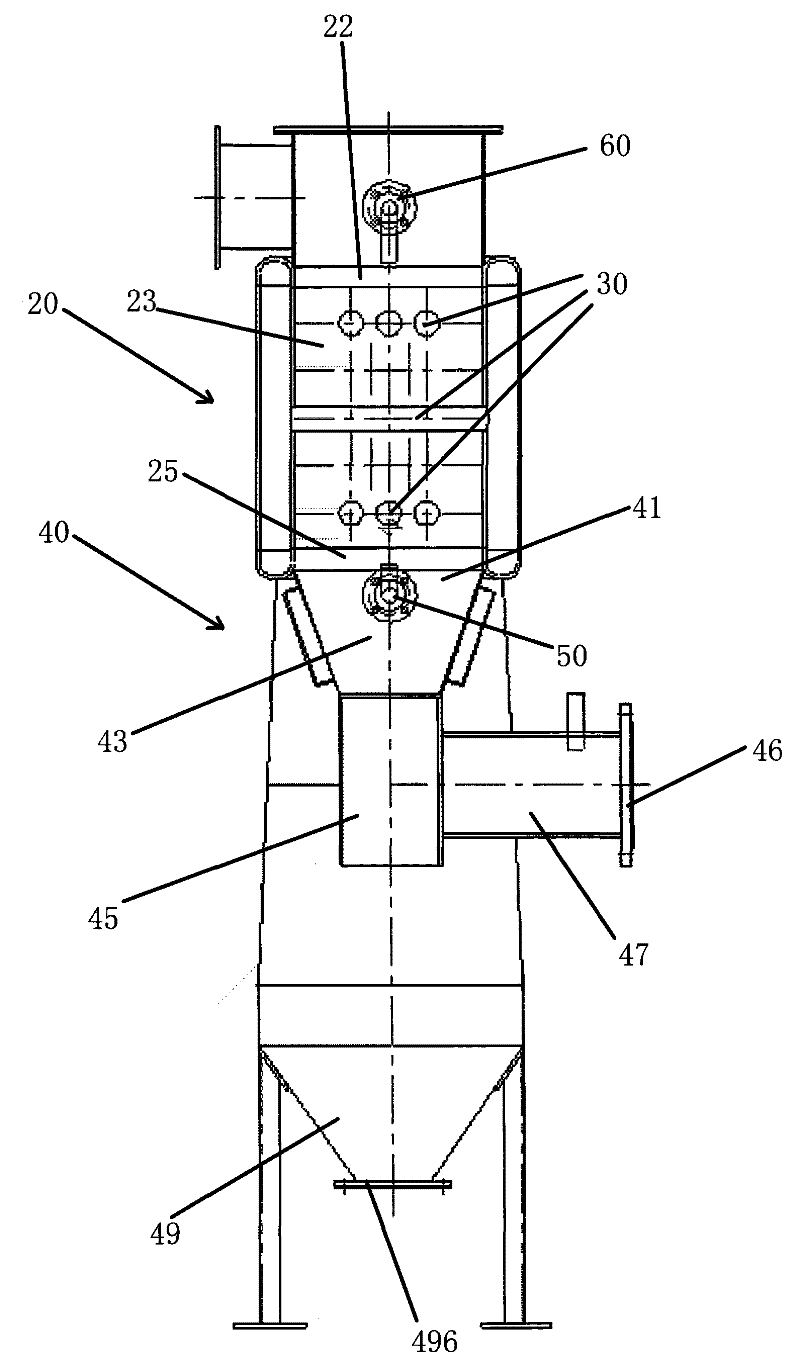

[0017] Please refer to FIG. 1 , the boiler flue gas dust removal and energy saving device of the present invention mainly includes two parts: a heat exchange unit 20 and a dust removal unit 40 .

[0018] The heat exchange unit 20 is provided with a high temperature flue gas inlet 22 , a low temperature flue gas outlet 25 and a heat exchange space 23 defined between the high temperature flue gas inlet 22 and the low temperature flue gas outlet 25 . Several heat exchange pipes 30 are arranged in the heat exchange space 23 , and a fluid (water in this embodiment) for exchanging heat with the flue gas circulates in the heat exchange pipes 30 .

[0019] According to the sequence from the high-temperature flue gas inlet 22 to the low-temperature flue gas outlet 25, the heat exchange pipes 30 are divided into five layers, and the heat exchange pipes 30 of each layer are respectively located in a plane parallel to the horizontal plane. Each layer includes three or more heat exchange p...

Embodiment 2

[0028] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0029] Another induced draft fan 60 is arranged in the high-temperature flue gas inlet 22 .

[0030] The heat exchange pipes 30 are divided into eight layers, and each layer includes six heat exchange pipes 30 . The orientation of the heat exchange tubes 30 in different layers can be rotated by 60 degrees relative to the orientation of the heat exchange tubes 30 in the adjacent layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com