Check valve for engine

A check valve and engine technology, applied in engine components, engine control, machine/engine, etc., can solve the problems of small gas flow cross-sectional area, large airflow resistance, and reduced reliability, and achieve small size, easy assembly, and sealing good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

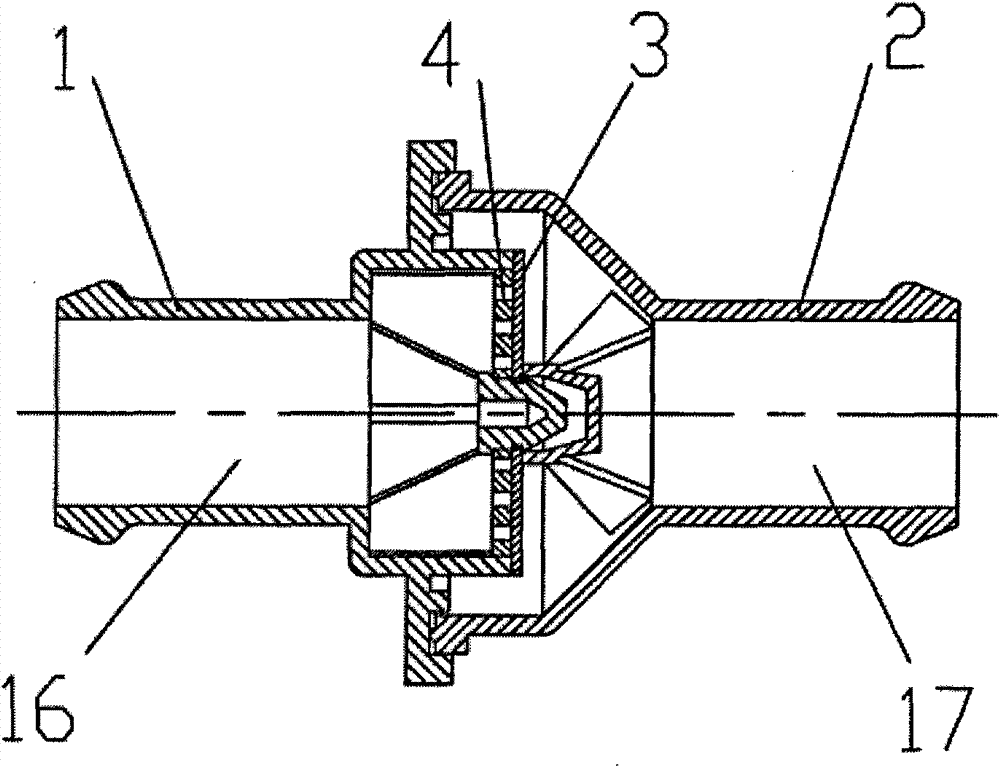

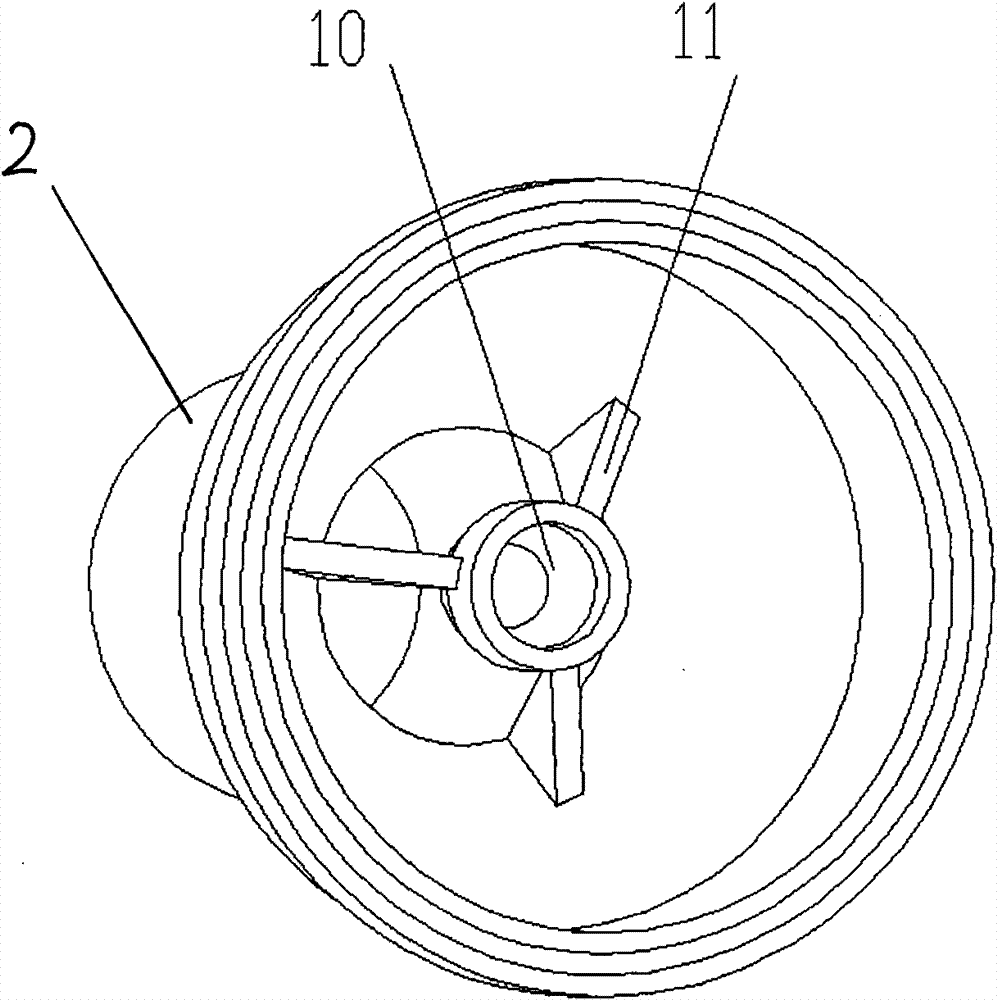

[0022] Such as figure 1 As shown, the one-way valve is composed of an upper casing 1 , a lower casing 2 , a diaphragm 3 and a supporting sheet 4 .

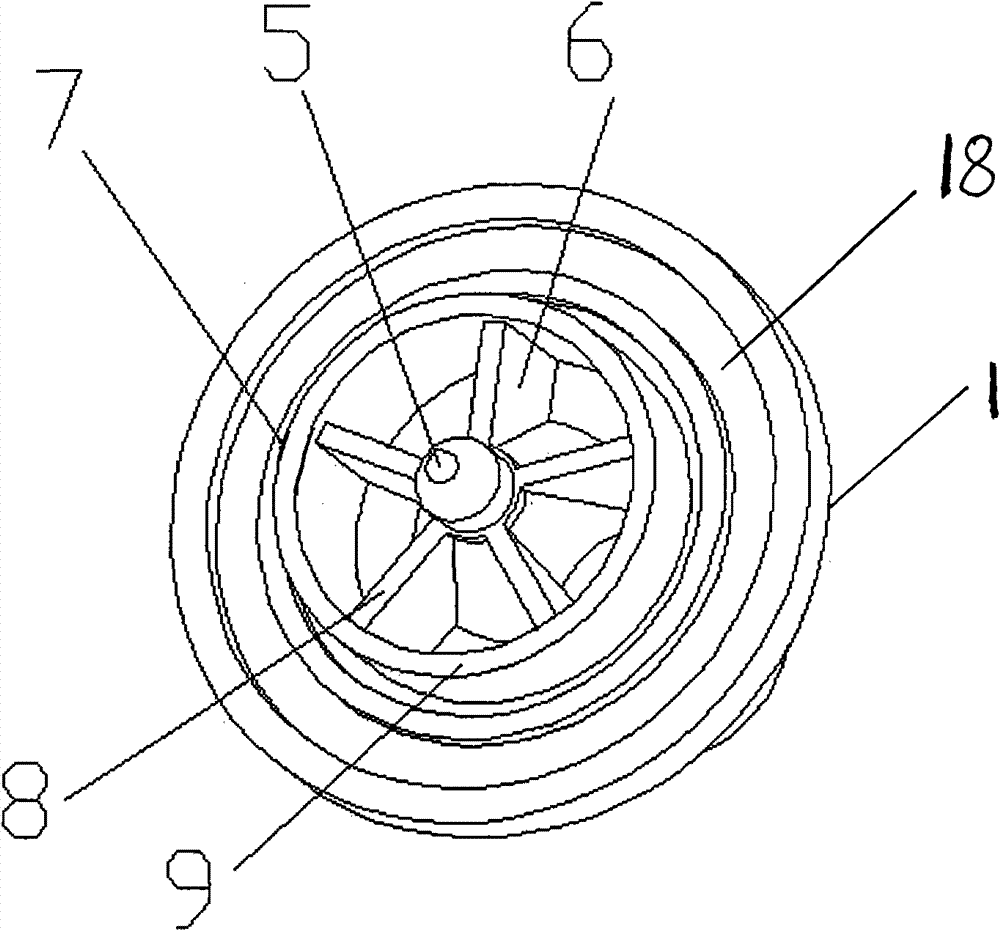

[0023] Such as figure 2 As shown, the upper casing 1 is two-section cylindrical, and the upper cylinder is slightly longer, which is the air inlet 16 of the whole valve (see figure 1 ), the lower section of the cylinder is the assembly part 7 for assembling the diaphragm 3 and the supporting sheet 4 of the upper shell, and an assembly ring 18 is formed on the outer periphery of the assembly part, which is connected and assembled with the lower shell 2 . There is a first positioning boss 5 in the center of the assembly part, and the first positioning boss 5 is supported by a positioning boss bracket 6 connected to the cylinder wall of the assembly part. There are multiple positioning boss supports 6 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com