Installation of new structure for air-gun combined dredging machine

An air cannon and dredging machine technology, which is applied in the field of mining machinery, can solve the problems of limited bending resistance, poor blocking and dredging effect, and difficult to start, and achieves reasonable installation structure design, flexible and labor-saving up and down movement, easy disassembly and assembly. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

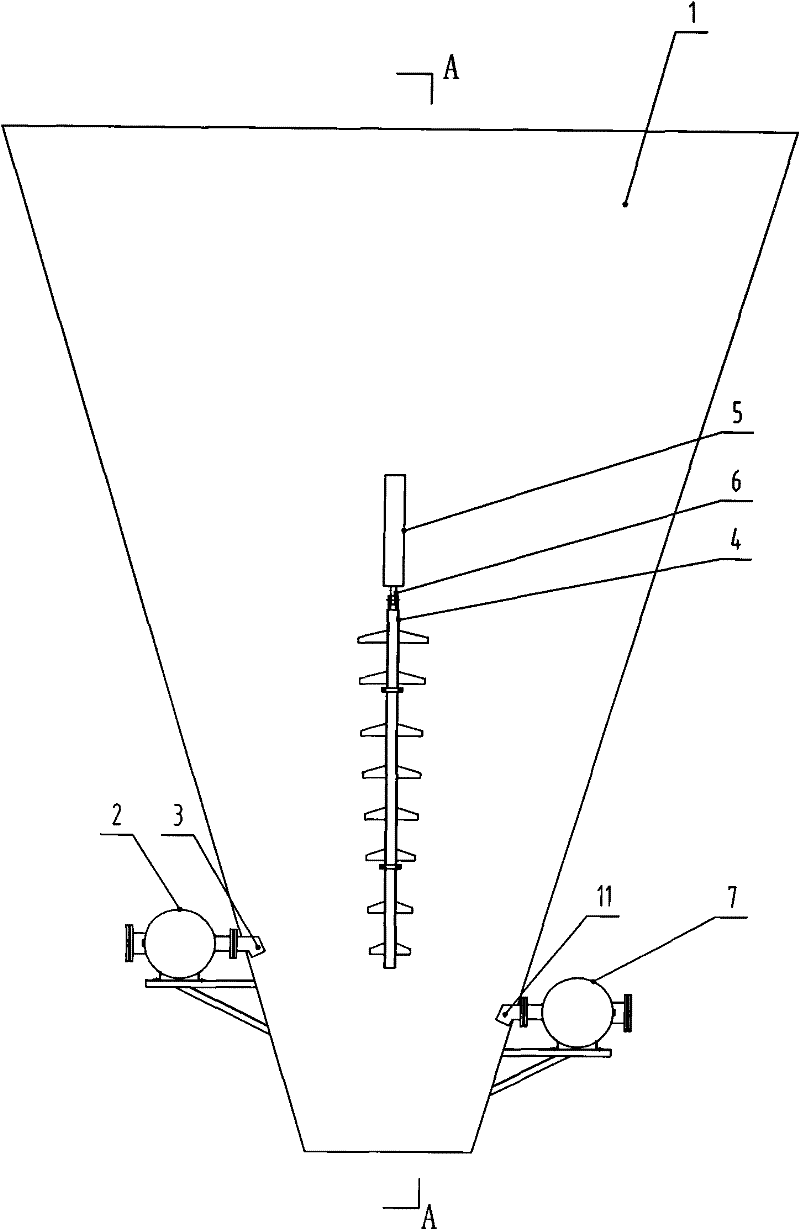

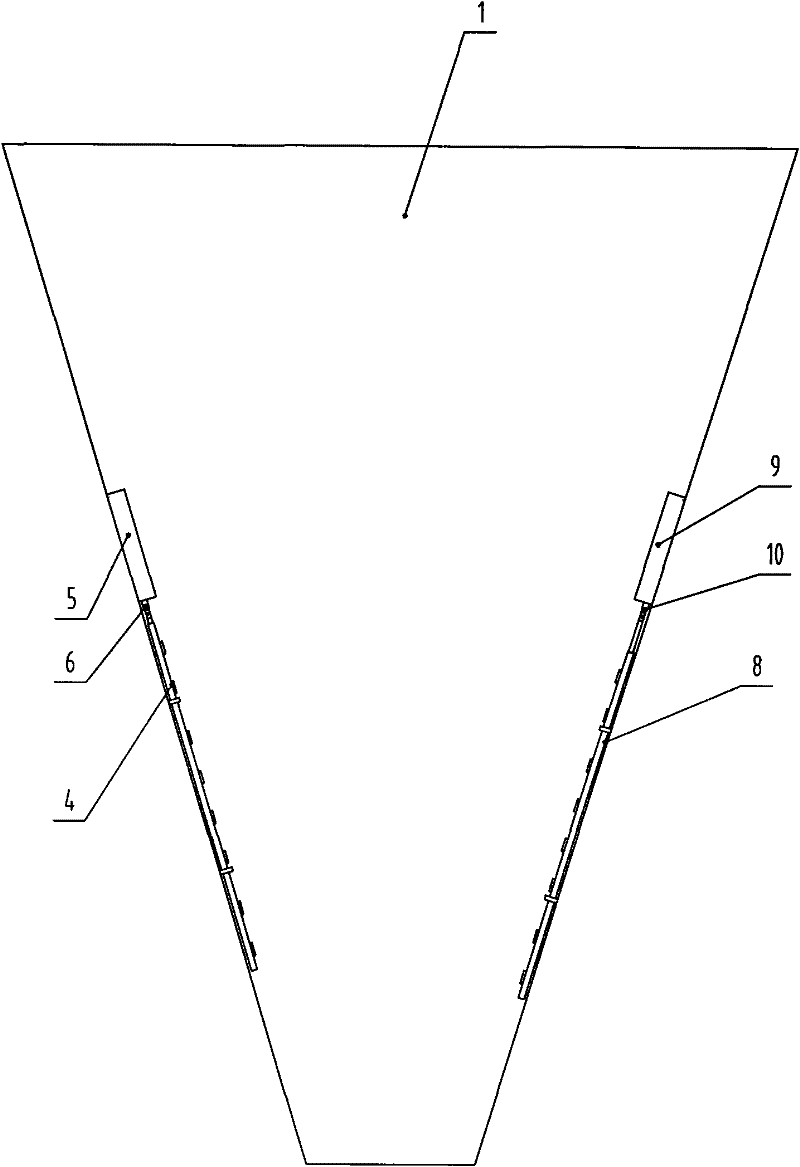

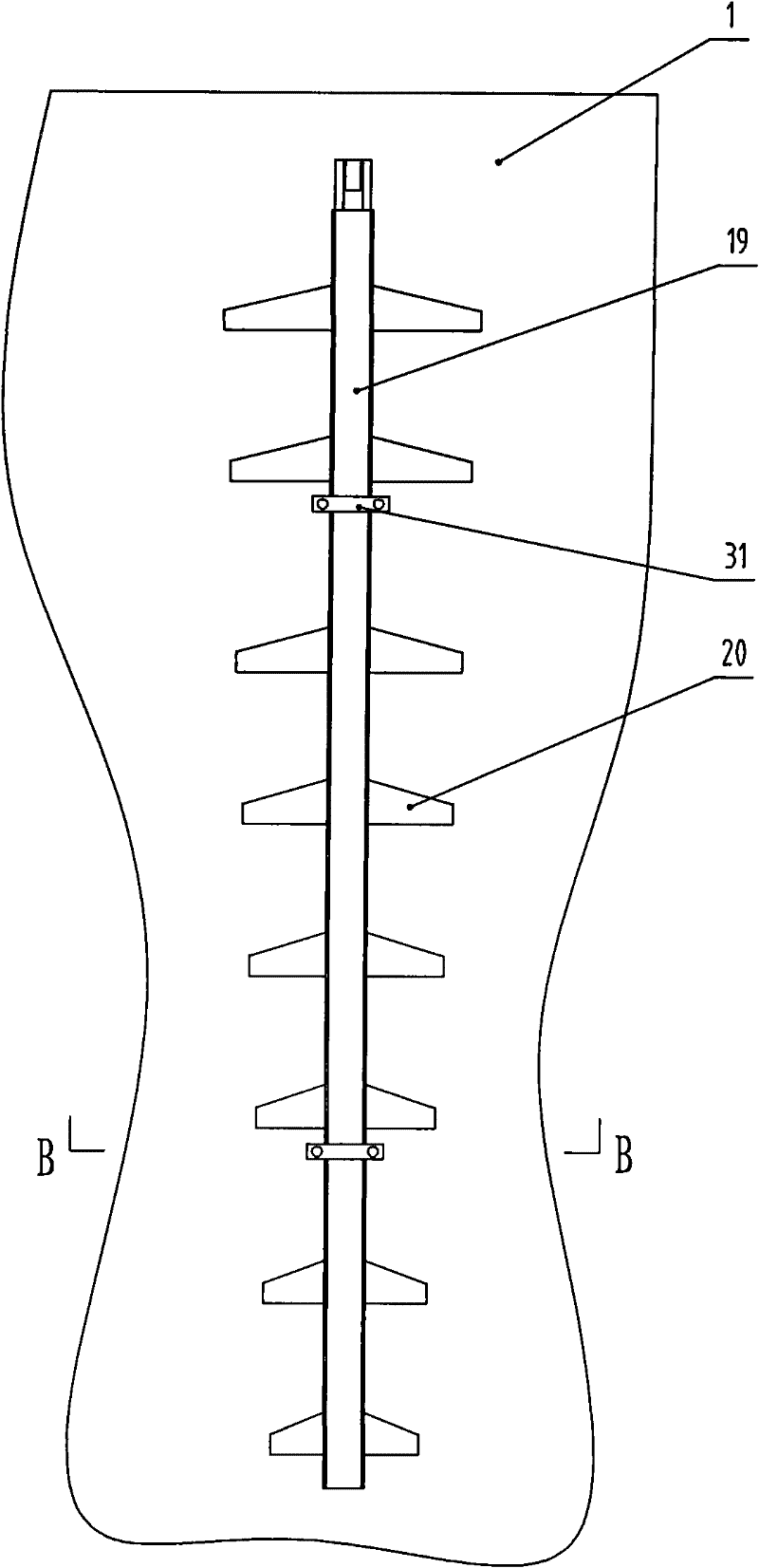

[0021] Such as figure 1 and figure 2 Shown, the air cannon combination dredging machine of the present invention installs new structure, comprises the conical silo 1 of up big and down small, and outside silo 1, left and right are oppositely provided with air cannon 2 and air cannon 7 (be prior art, specific structure No longer repeat), the position of the air cannon 2 is higher than the air cannon 7, and the air nozzle 3 and the air nozzle 11 of the air cannon 2 and the air cannon 7 are arranged obliquely downward in the feed bin 1, and the front and back of the feed bin 1 inner wall are oppositely provided with Dredge 4, hydraulic cylinder 5, dredge 8, hydraulic cylinder 9, hydraulic cylinder 5 and hydraulic cylinder 9 are respectively located above dredge 4 and dredge 8, piston 6 of hydraulic cylinder 5 is connected to the top of dredge 4 by transmission, hydraulic pressure The piston 10 of the cylinder 9 is connected to the top of the dredge 8 in transmission. The heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com