Steel-band reinforced steel plastic composite wound pipe

A technology for winding pipes and steel strips, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc. It can solve the problems of large traction resistance, low axial tensile strength of composite wound pipes, and difficulty in spiral winding of square pipes. Achieve the effect of reducing the cost of pipe making and increasing the axial tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

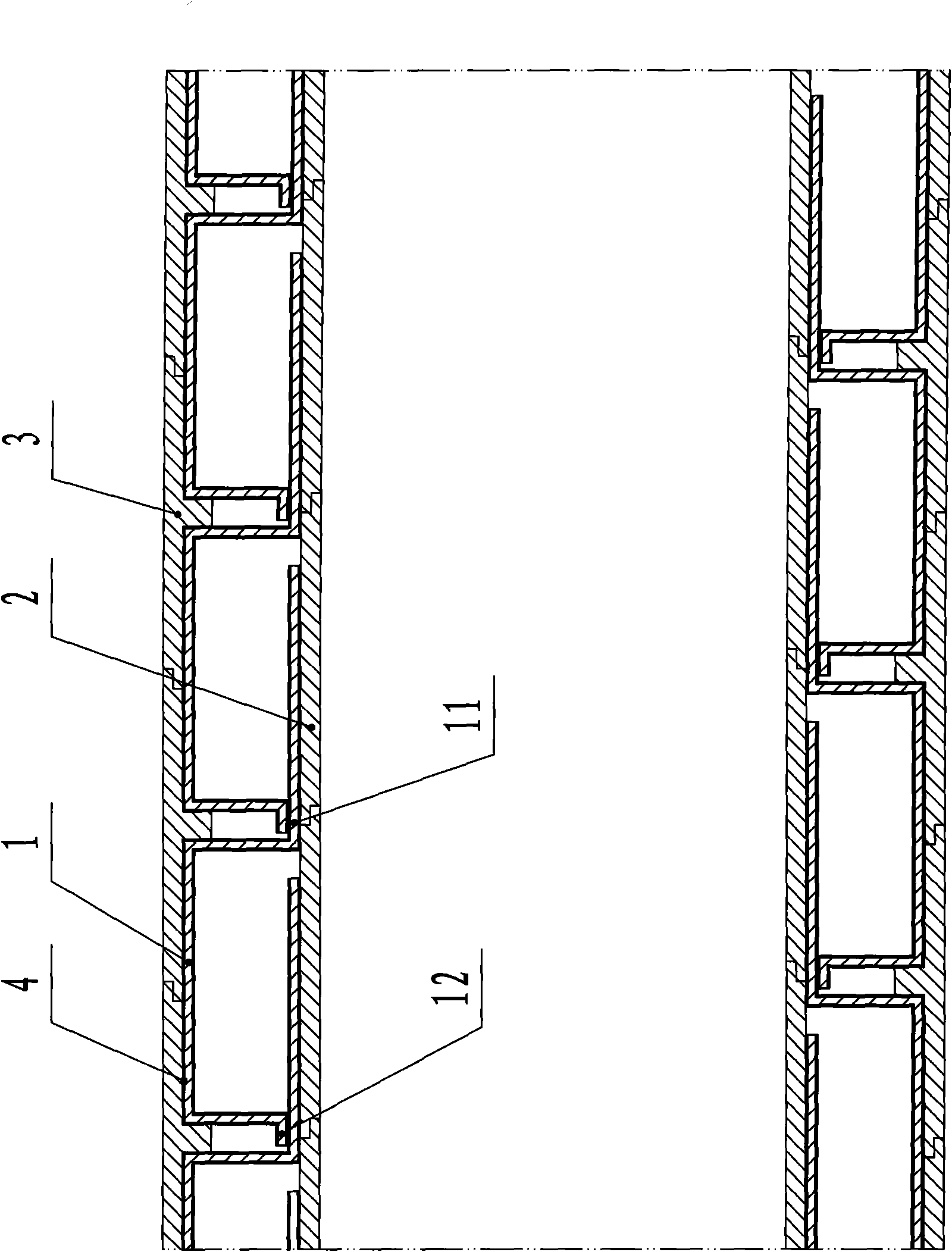

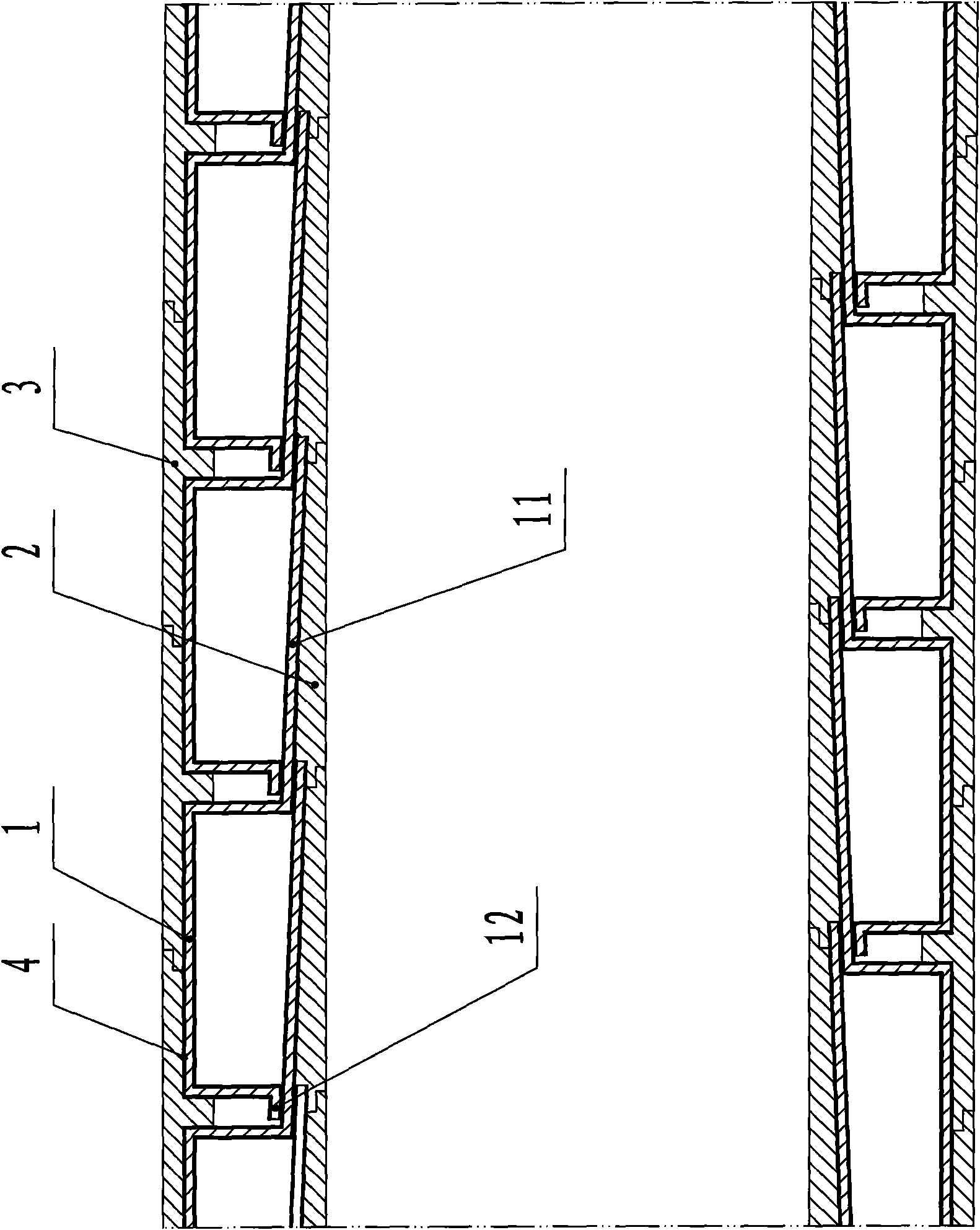

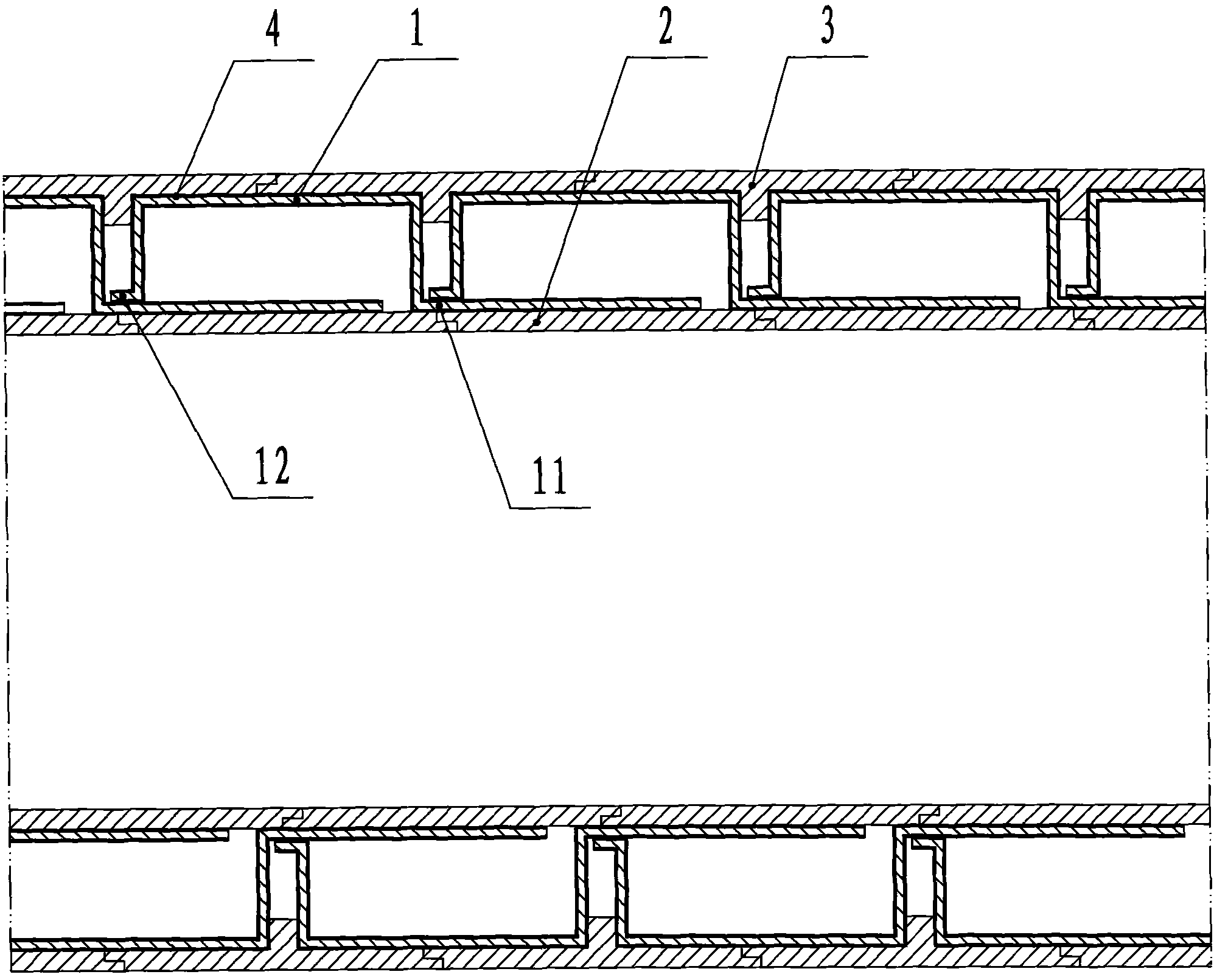

[0012] The steel-belt-reinforced steel-plastic composite winding pipe of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, it is a steel-belt-reinforced steel-plastic composite winding pipe of a structure, which includes a pipe wall skeleton formed by winding a formed steel belt 1. The cross-section of the formed steel belt 1 includes a long leg 11 and a short leg 12 is in the shape of the word "几", and the surface of the formed steel strip 1 has an adhesive layer 4, so that the formed steel strip 1 can be firmly bonded to the inner pipe wall 2 and the outer pipe wall 3. When the formed steel strip 1 is wound, the The short legs 12 of one circle of formed steel belt 1 are superimposed on the long legs 11 of the previous circle of formed steel belt 1, a certain distance is left between the long legs 11 of the front circle and the long legs 11 of the rear circle, and the pipe wall sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com