Bearing tuffitriding frame

A technology of nitrocarburizing material frame and material frame, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., and can solve the problems of large space occupied by the material frame, less furnace loading, and limited production efficiency. Achieve the effect of increasing furnace loading, improving production efficiency, and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

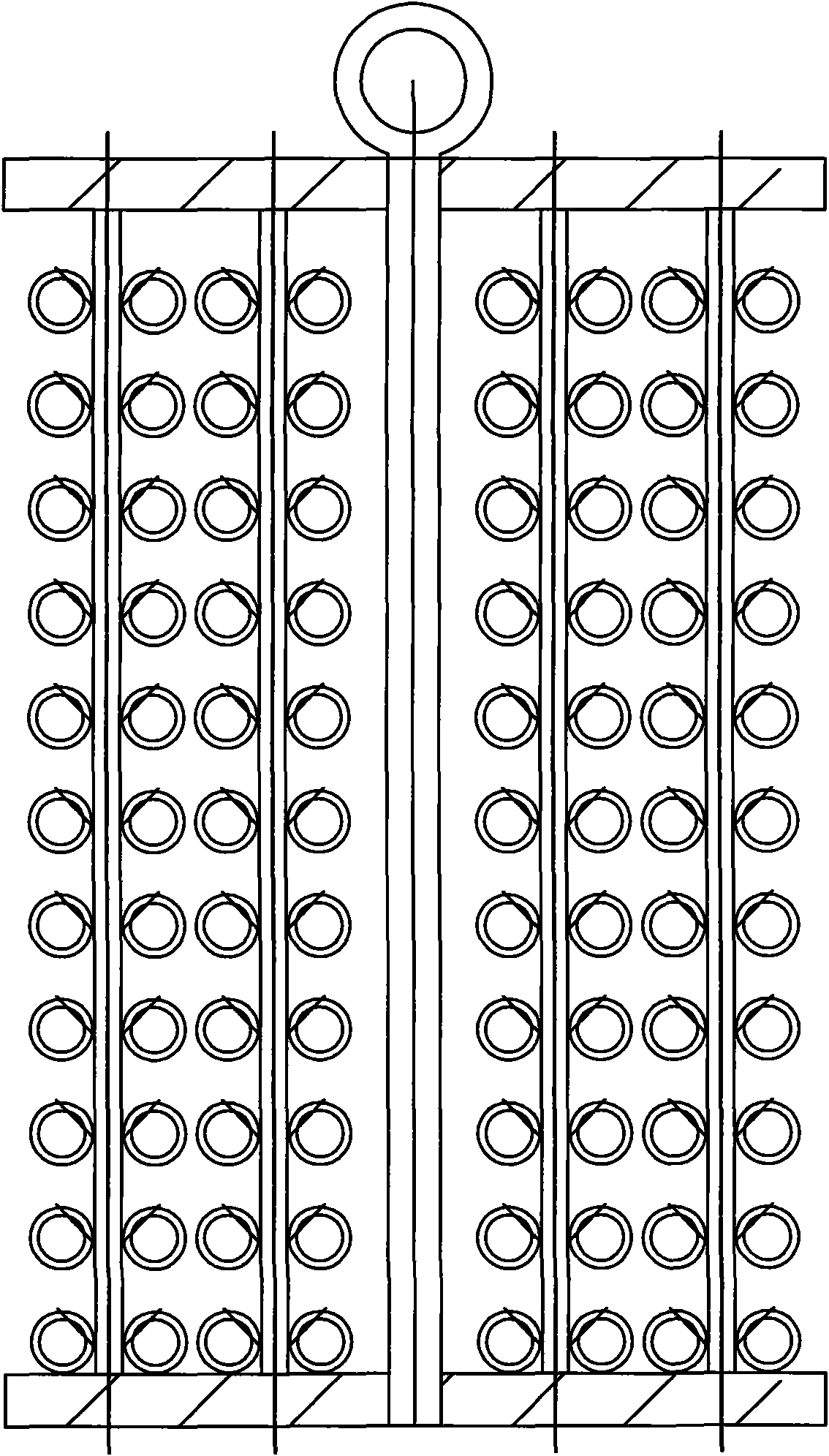

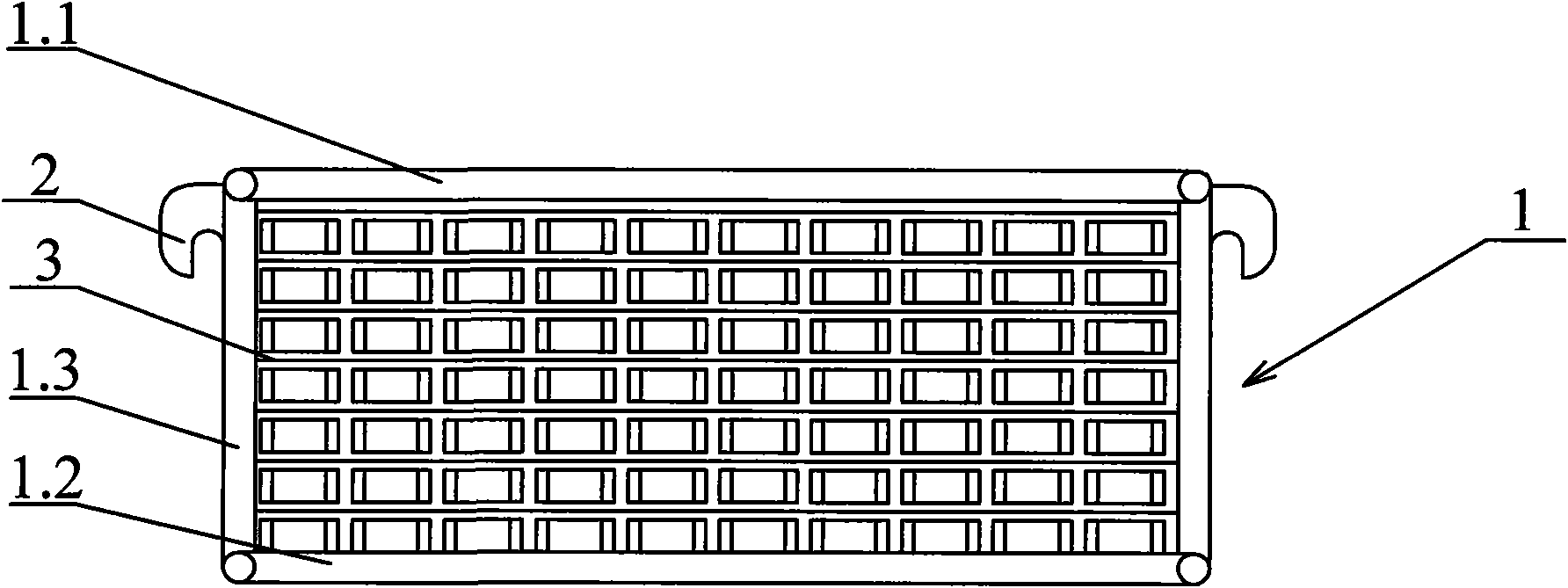

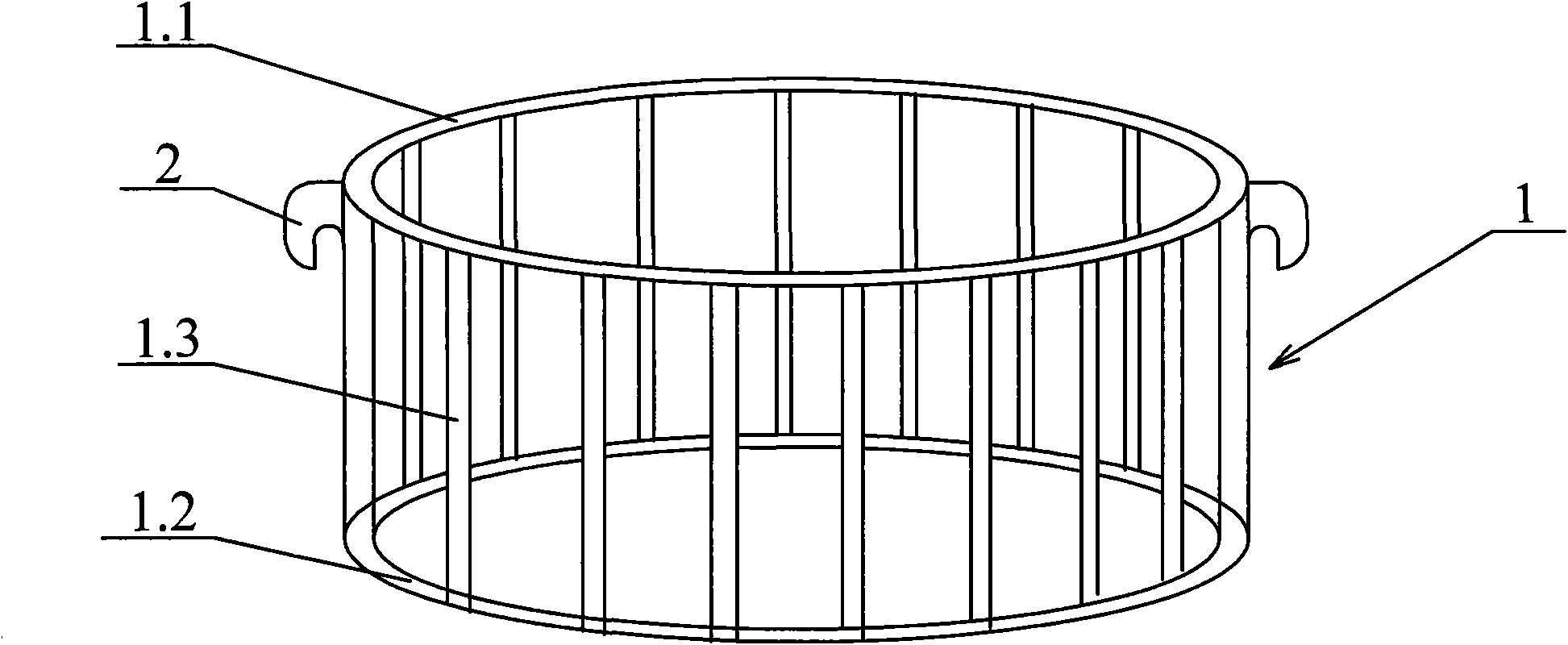

[0015] As shown in the figure: the nitrocarburizing material frame of the bearing includes a barrel-shaped material frame 1, the side wall of the barrel-shaped material frame 1 and the bottom of the barrel all have air holes, and the top end of the side wall of the barrel-shaped material frame 1 is fixed with a Two or more hanging buckles 2 are provided with several layers of isolation nets 3 in the barrel-shaped material frame 1 .

[0016] The cross-section of the isolation net 3 is wave-shaped, which can ensure that the gas components in the furnace enter the barrel-shaped material frame 1 conveniently.

[0017] The hanging buckles 2 are evenly distributed on the top end of the side wall of the barrel-shaped material frame 1, and all the hanging buckles 2 are arranged at the same height.

[0018] The barrel-shaped material frame 1 includes a top ring body 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com