Sapphire infrared window cleaning agent and preparation method

A technology of infrared window and cleaning agent, applied in the field of cleaning agent, can solve the problems of polishing surface damage, troublesome use, corrosion of sapphire window polishing surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

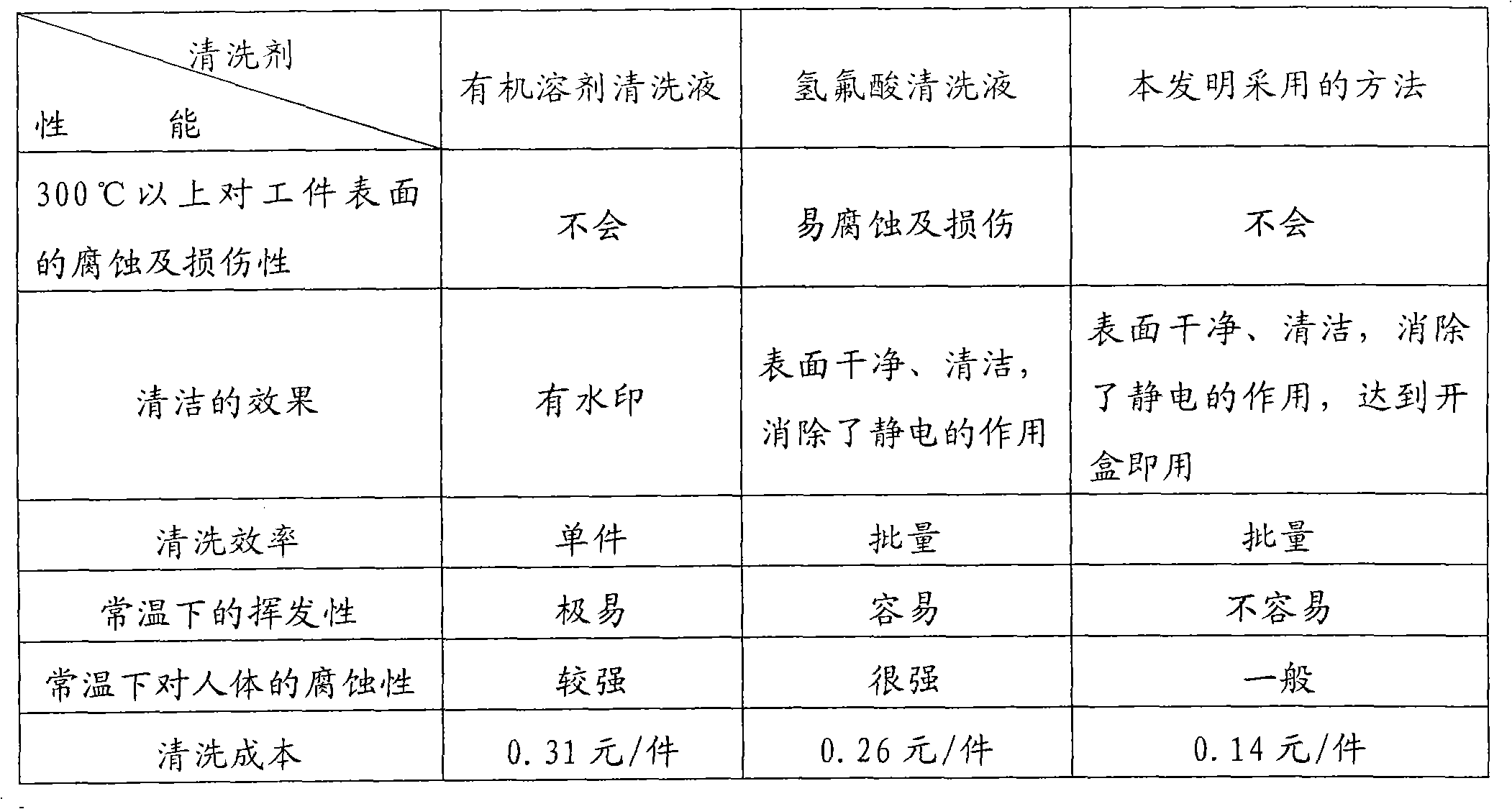

Image

Examples

Embodiment Construction

[0022] The components of the sapphire infrared window cleaning agent are configured as described in Table 2:

[0023] Table 2

[0024] serial number

Concentrated sulfuric acid (g)

Potassium dichromate (g)

water (g)

1

1472

320

4000

2

1656

360

450

3

1840

400

5000

[0025] The specific production steps of sapphire infrared window cleaning agent are as follows:

[0026] (1) Weighing: Put a layer of clean newspaper on the electronic balance, take out the potassium dichromate with a medicine spoon and place it on the newspaper, and accurately weigh the weight of the potassium dichromate as described in Table 2. Wear protective gloves during the whole process, and do not touch potassium dichromate with your hands.

[0027] (2) Potassium dichromate solution is prepared: in a 5000ml beaker, accurately measure deionized water as described in Table 2, pour the weighed potassium dichromate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com