Opposite piston type engine

A piston engine and piston technology, applied to internal combustion piston engines, engine components, combustion engines, etc., can solve problems such as adverse effects and heat energy not being converted, and achieve the effects of improving efficiency, reducing oil consumption and avoiding energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

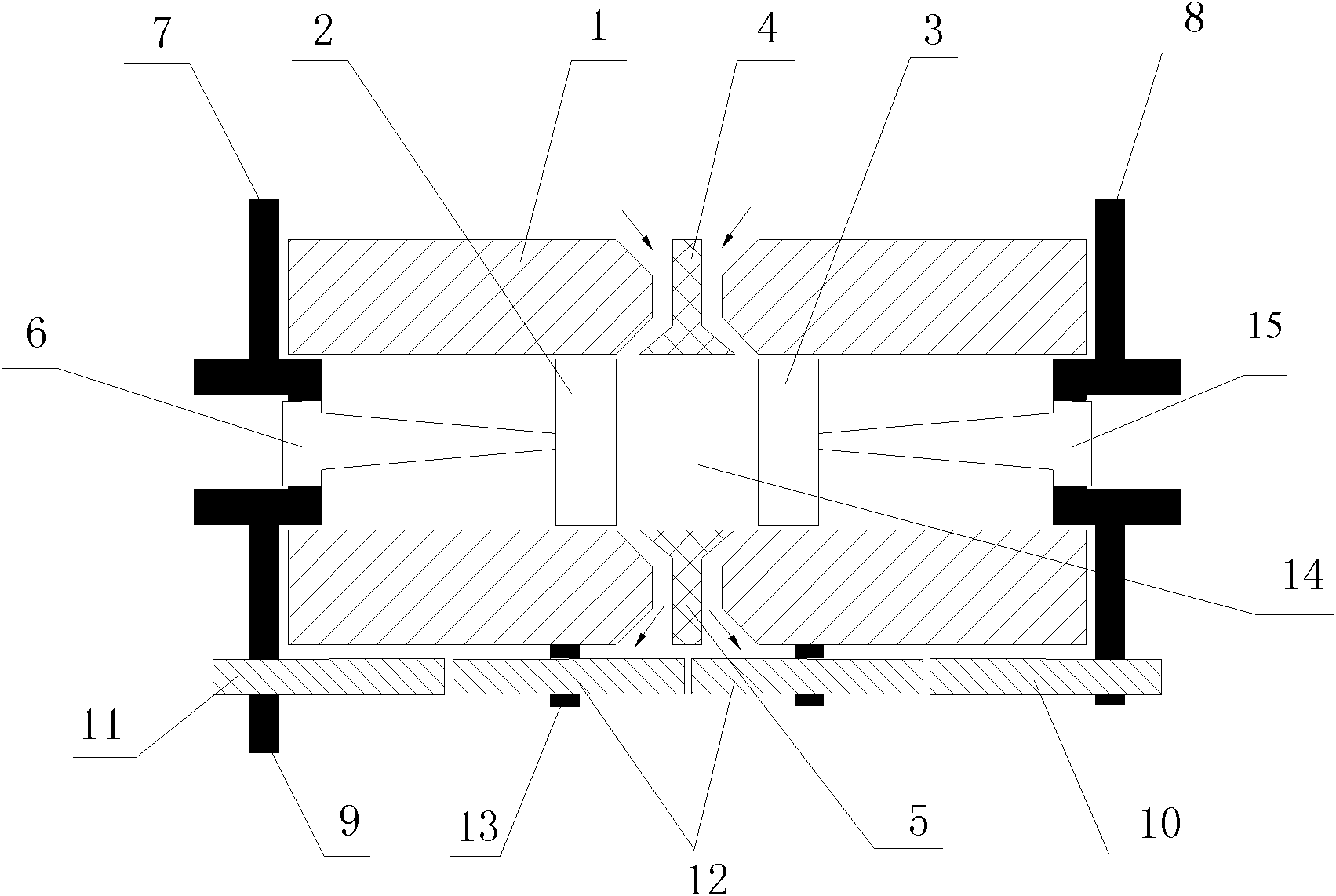

[0024] see figure 1 , the relative piston engine proposed by the present invention includes a cylinder body 1, a first piston 2, a second piston 3, an intake valve 4, an exhaust valve 5, a first connecting rod 6, a first crankshaft 7, and a second crankshaft 8 , output shaft 9, driving wheel 10, output wheel 11, reversing wheel 12, wheel shaft 13, combustion chamber 14, second connecting rod 15; from figure 1 Look, the first piston 2 and the second piston 3 are located on the same axis, and their positions in the cylinder 1 are symmetrical with respect to the intake and exhaust valves. They move relative or opposite, and the intake valve 4 and the exhaust valve 5 are set In the middle of the cylinder block 1, the cavity between the first piston 2 and the second piston 3 together forms a combustion chamber 14. The first piston 2 is connected to the first crankshaft 7 through the first connecting rod 6, and the second piston 3 is connected to the first crankshaft 7 through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com