Flat shim plate-adjustable grouting installation method

An installation method and a technology of flat pads, which are applied in the processing of building materials, infrastructure engineering, construction, etc., can solve problems such as extended construction period, long time for grouting, and increased construction difficulty, and achieve the effect of reducing costs and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

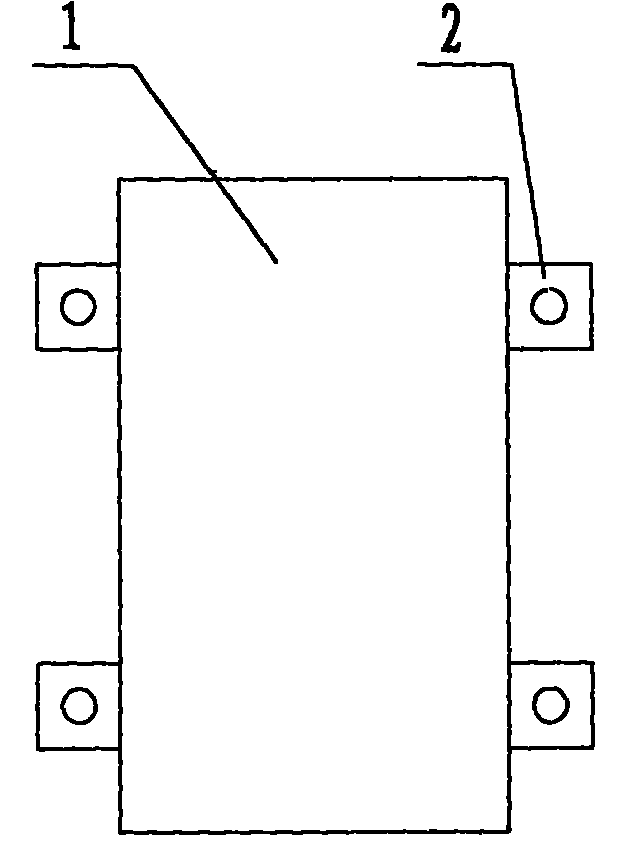

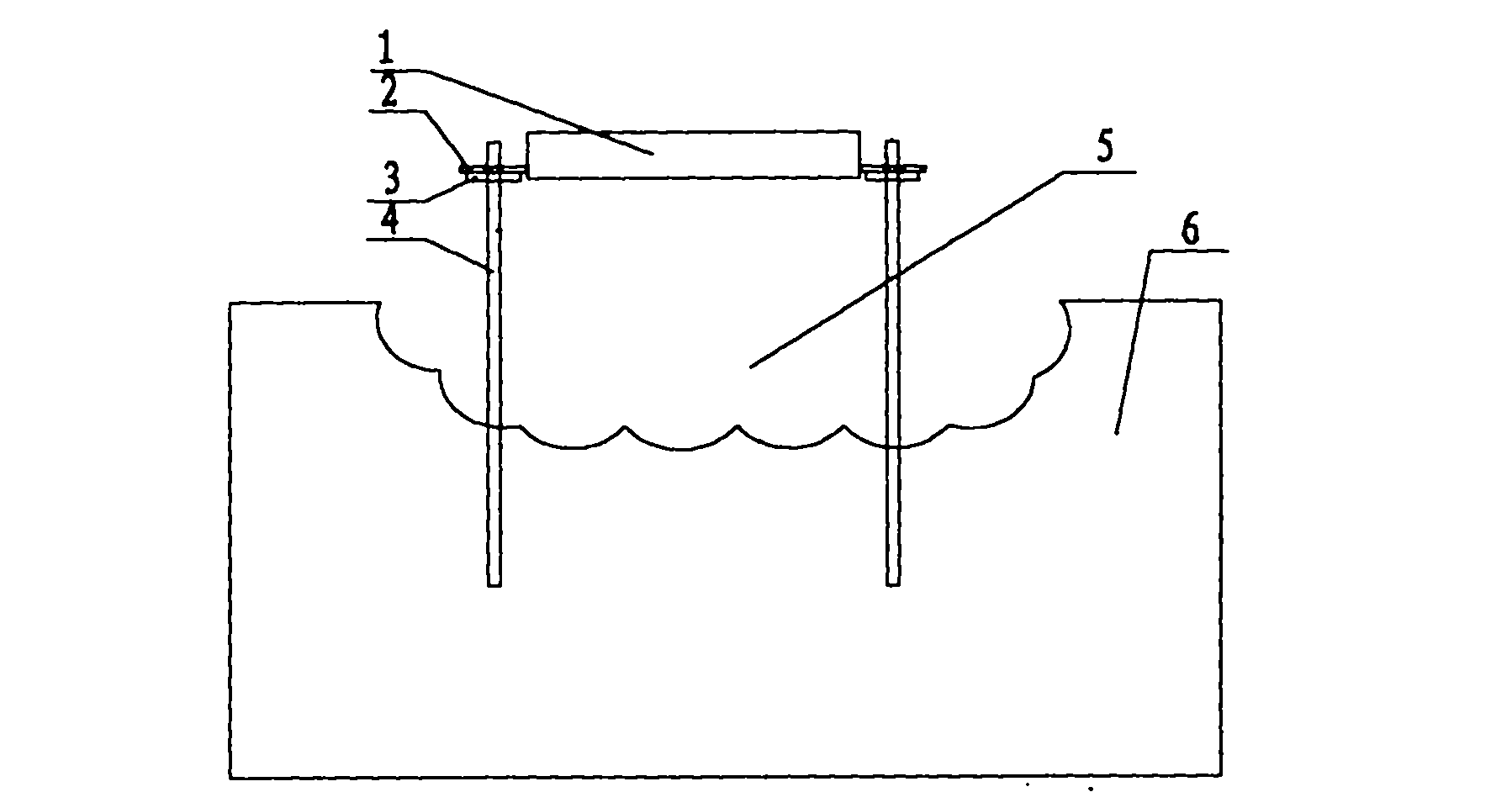

[0011] (1) The steel column structure installation of the main factory building of Pugang Luojing Relocation Project adopts the installation method of the adjustable flat pad. Each steel column uses 12 sets of adjustable flat pads, and the flat pad is 120×240 × 20mm, 4 sets of adjusting nuts and screws are M12 × 50; K, J, H series workshops have a total of 45 steel columns, directly saving economic costs: 45 × 12 × 53 yuan = 28620 yuan.

[0012] (2) For the installation of various structural equipment in the second-step Luojing project of Pudong Iron and Steel Co., Ltd., the adjustable seat slurry installation method of this flat backing plate is adopted. A total of 400 sets of flat backing plates are used, and the size of the flat backing plate is 120×240×20mm. 4 sets of adjusting nuts and screw rods are M12×50; directly save economic costs: 400×53 yuan=21200 yuan.

[0013] Fees are calculated based on:

[0014] ①. To install the structure or equipment using the traditional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com