Dry powder mortar

A technology of dry powder mortar and mortar, which is applied in the field of building materials, can solve problems such as the shortage of yellow sand resources and the shortage of dry powder mortar raw materials, and achieve the effects of promoting promotion, solving stacking problems, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

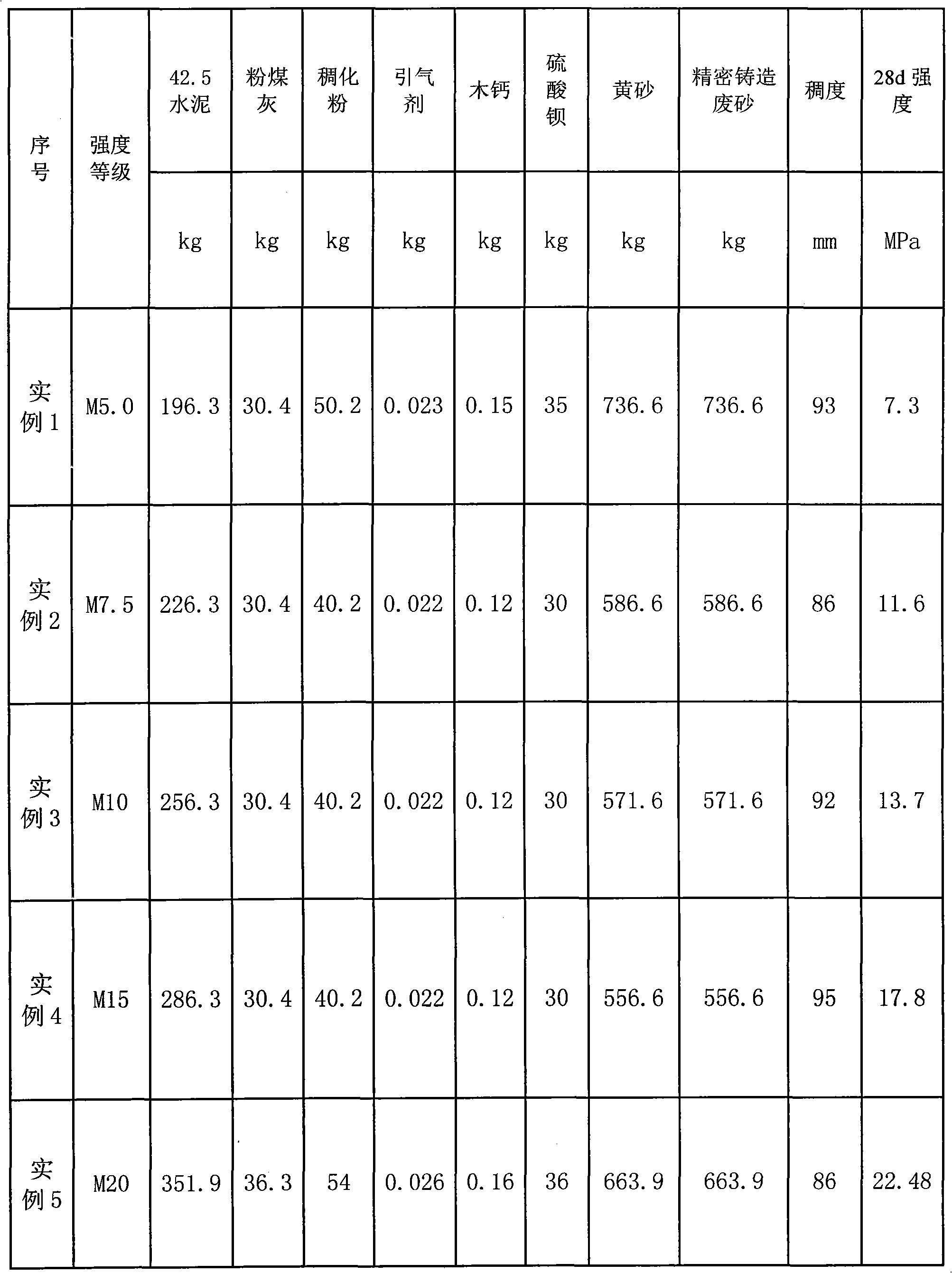

[0023] Examples 1-5, according to the mass ratio in Table 1, weigh different raw materials and mix evenly, add 17-22% water and stir evenly. The cement used in the test is 42.5 ordinary Portland cement, the fineness modulus of yellow sand is 2.5, the fineness modulus of precision casting waste sand is 1.8, and the fly ash is Class II ash.

[0024] It can be seen from the test results in Table 1 that when the ratio of waste sand to sand in precision casting is 50%, with the increase of cement dosage and lime-sand ratio, dry powder mortar with different strength levels of 5-20 MPa can be prepared.

[0025] Table 1 Preparation of dry powder mortar with different strength grades in the case of mixing yellow sand and precision casting waste sand

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com