Method for recovering waste heat of electrically fused magnesium fused weight

A technology of fused magnesium and magnesium fused lumps, which is applied in the field of fused magnesia smelting, can solve problems such as waste of resources, increased energy consumption, and waste heat loss, and achieve the effects of improving productivity, optimizing energy, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

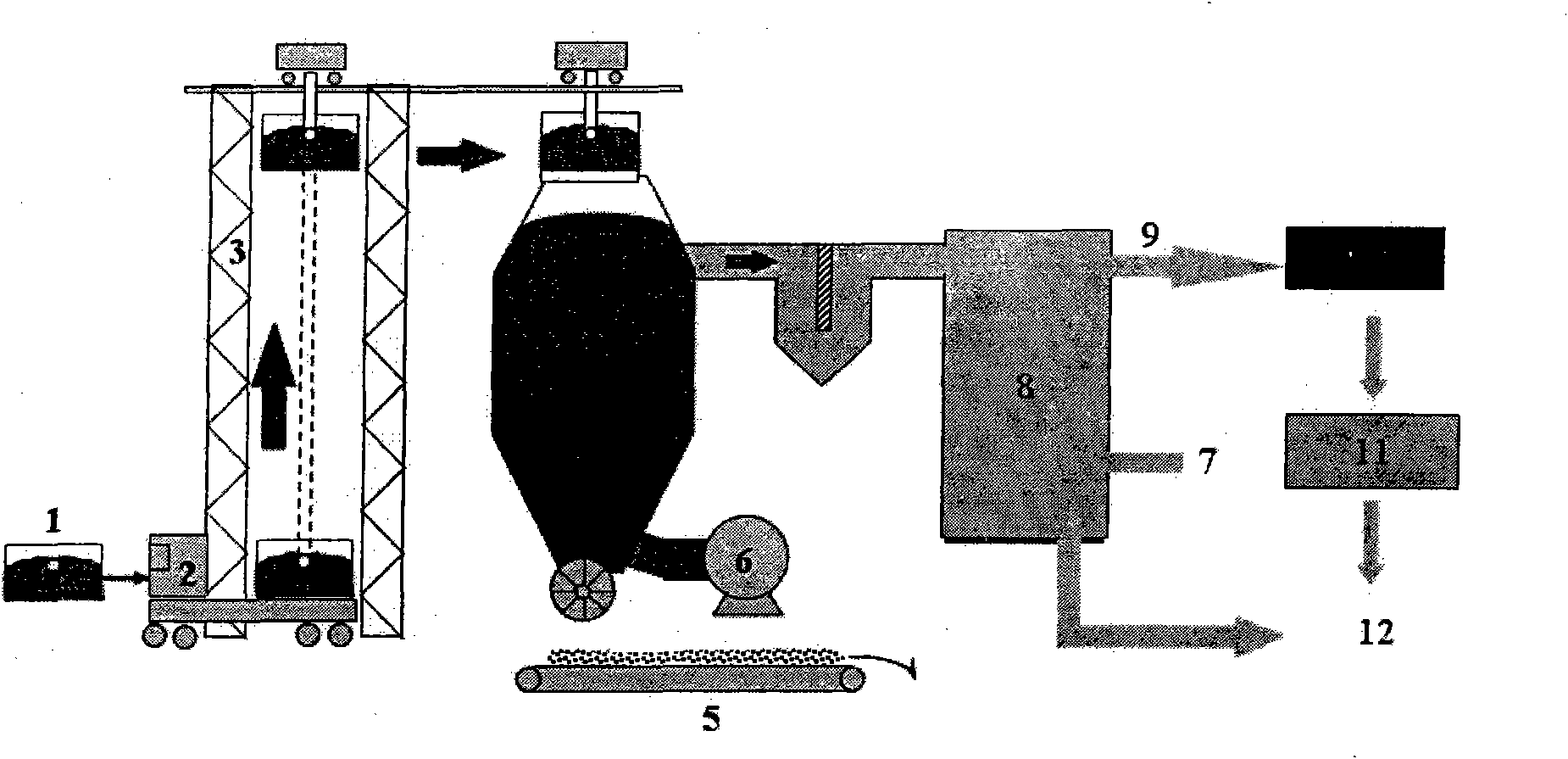

[0015] 1. For the waste heat recovery process of 10t high-temperature magnesium fused mass, a dry quenching and crushing device is used for waste heat recovery, and the air flow rate is 180,000-230,000m 3 / h; after crushing, the particle size of fused magnesium is controlled at 20-200mm. The temperature of the discharged fused magnesium is 100-300°C.

[0016] 2. For the waste heat recovery process of 12t high-temperature magnesium fused mass, a dry quenching and crushing device is used for waste heat recovery, and the air flow rate is 200,000-250,000m 3 / h; after crushing, the particle size of fused magnesium is controlled at 20-200mm. The temperature of the discharged fused magnesium is 100-300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com