Online monitor of continuous casting machine crystallizer foot roll working state and monitoring method thereof

A working state, continuous casting machine technology, applied in the field of steelmaking and continuous casting, can solve problems such as undiscovered application precedents and technical reports, improve the level of automation and intelligence, reduce labor intensity and danger, and have broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with embodiment.

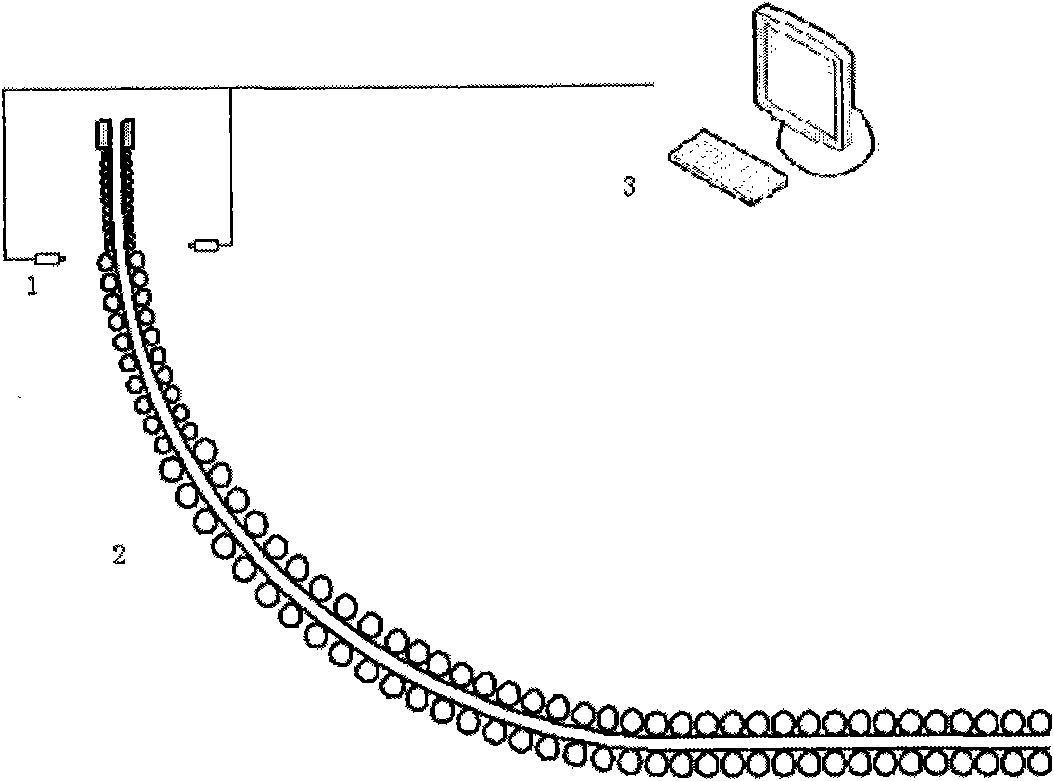

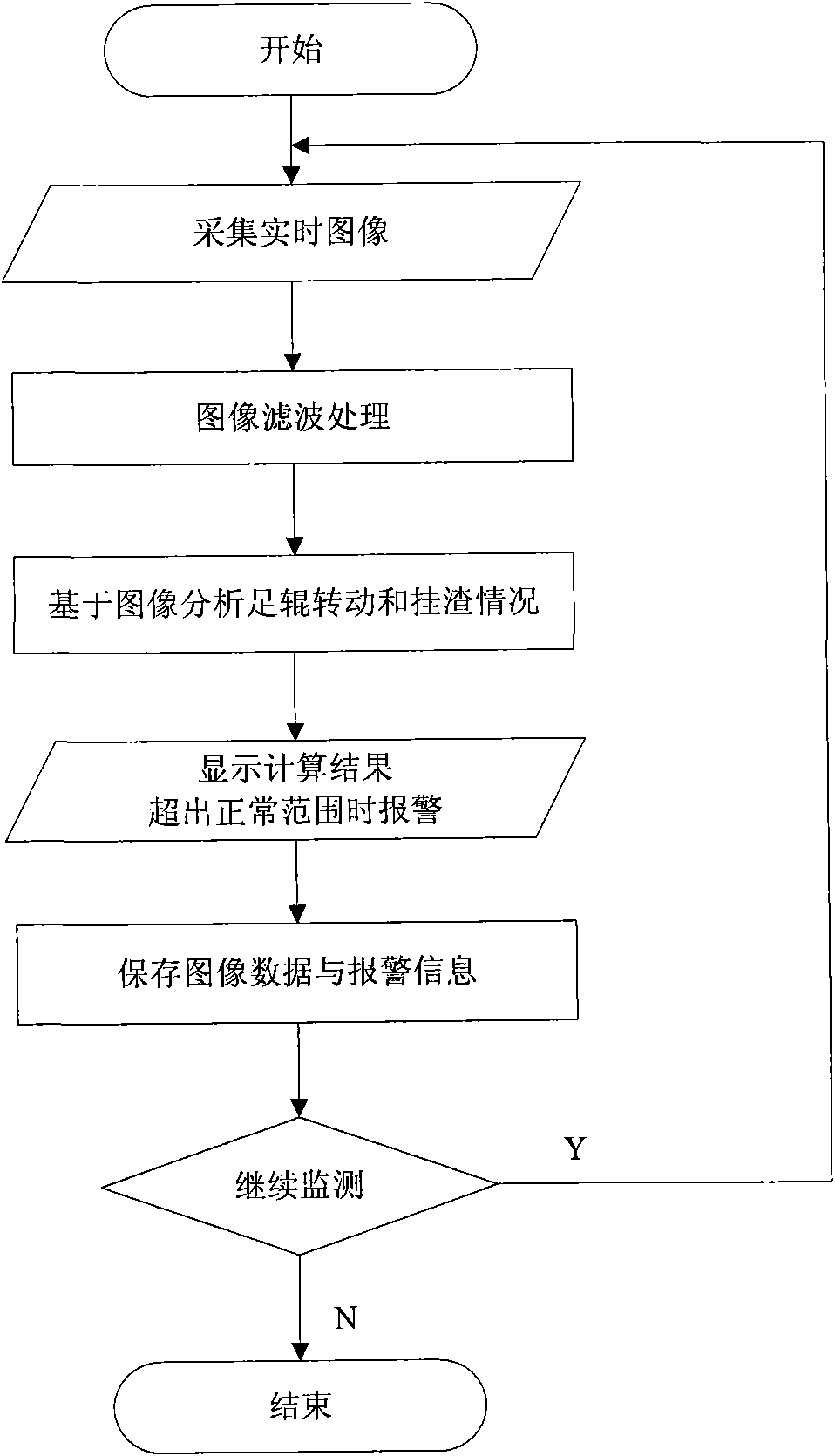

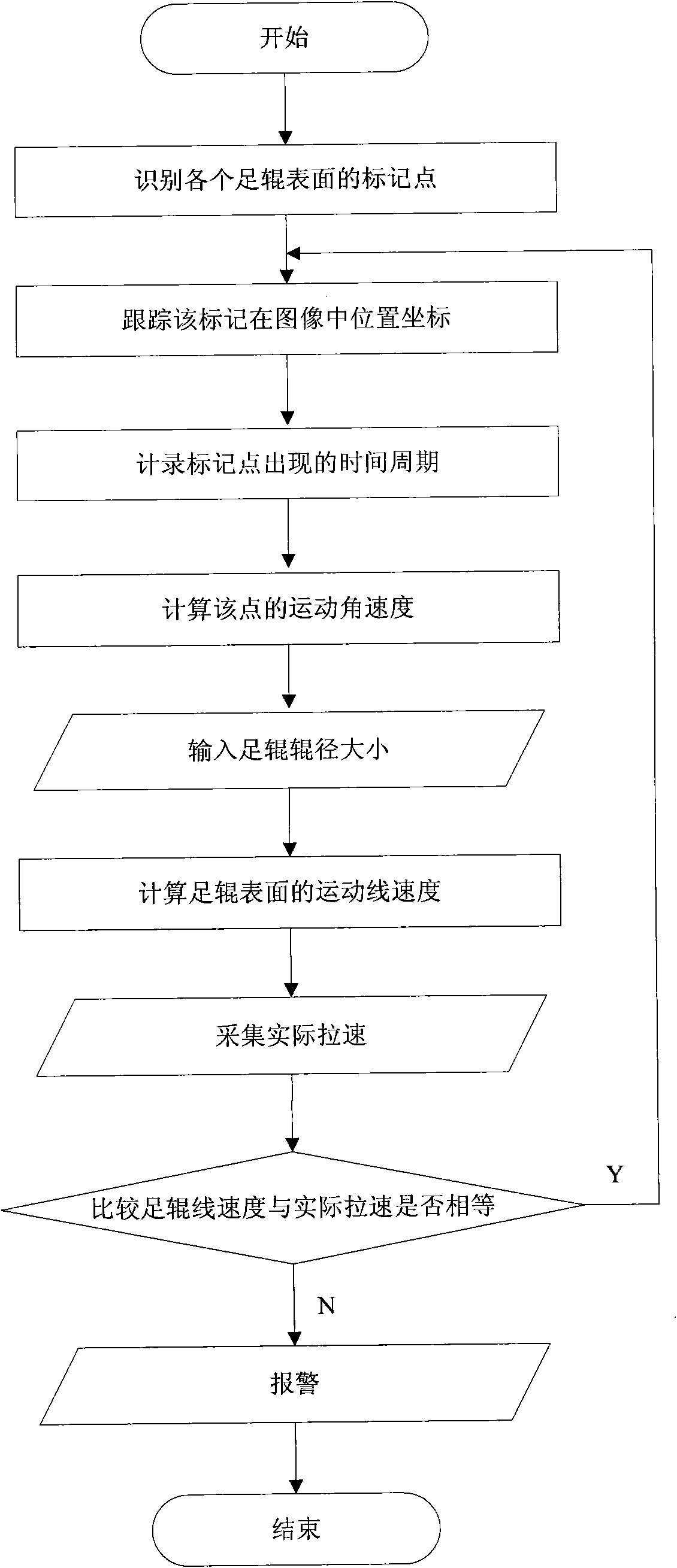

[0045] like figure 1As shown in Fig. 2, a fixed frame is welded at appropriate parts on both sides of the inner and outer arcs of the foot roll area of the continuous casting machine, and a color area array CCD camera is respectively installed at a designated position about 3m away from the foot roll. Full image of the cast strand. The camera is aimed vertically at the monitoring point (surface) as much as possible, and the deviation angle is controlled within 0°~30°. There is a protective cover outside the camera, and there is an N 2 Gas blown to seal. The color image acquisition card is selected, and the sampling speed of 24bit images at 25 frames per second can be realized at 800×640 resolution and transmitted to 3 industrial computers. In addition to collecting video image data in real time, the industrial computer can also communicate directly with the on-site PLC equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com