Complete compound granular feed and preparation method and application thereof

A pellet feed, full price technology, applied in application, animal feed, animal feed, etc., to promote standardization, reduce the incidence of diseases, and increase growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

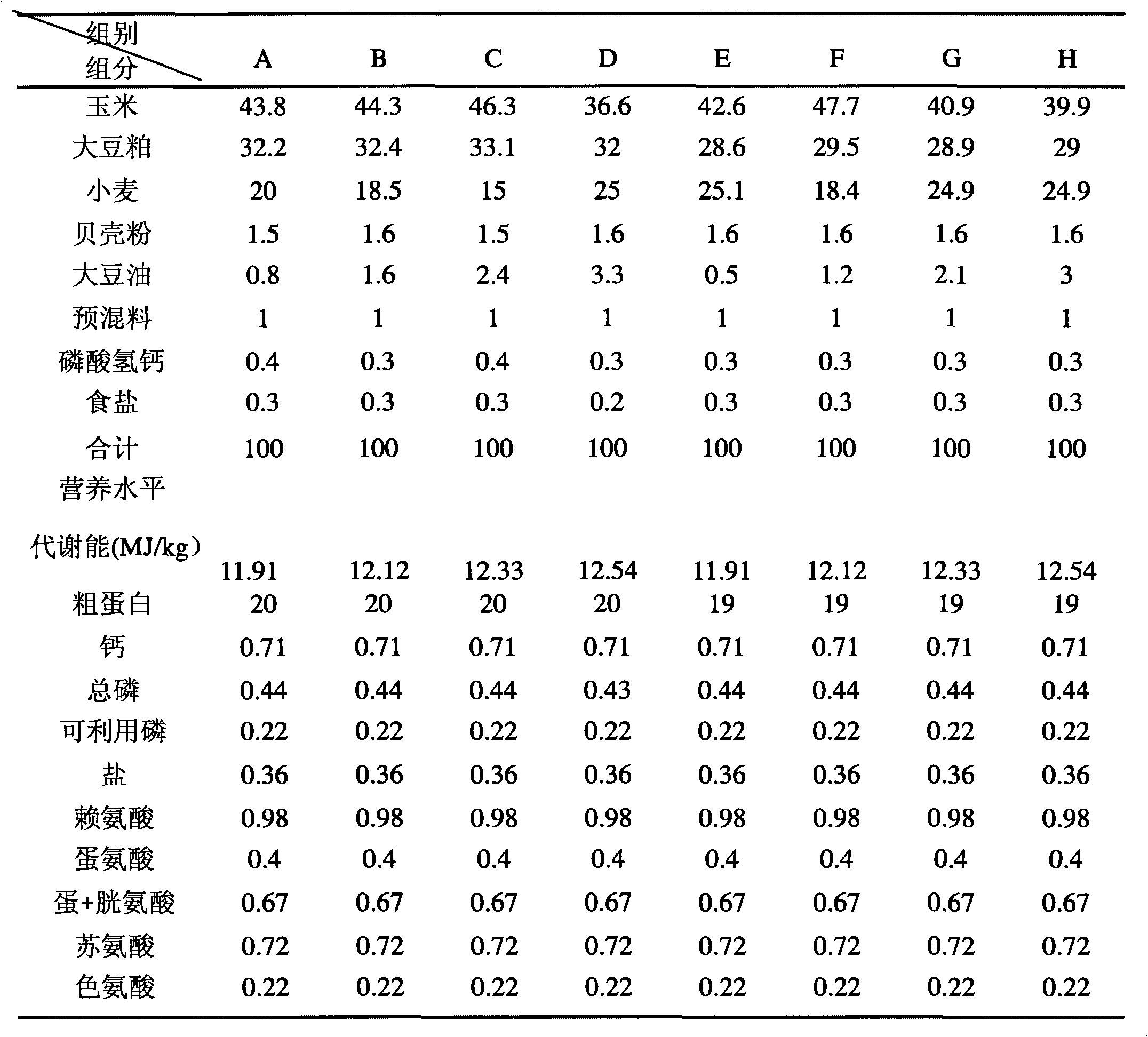

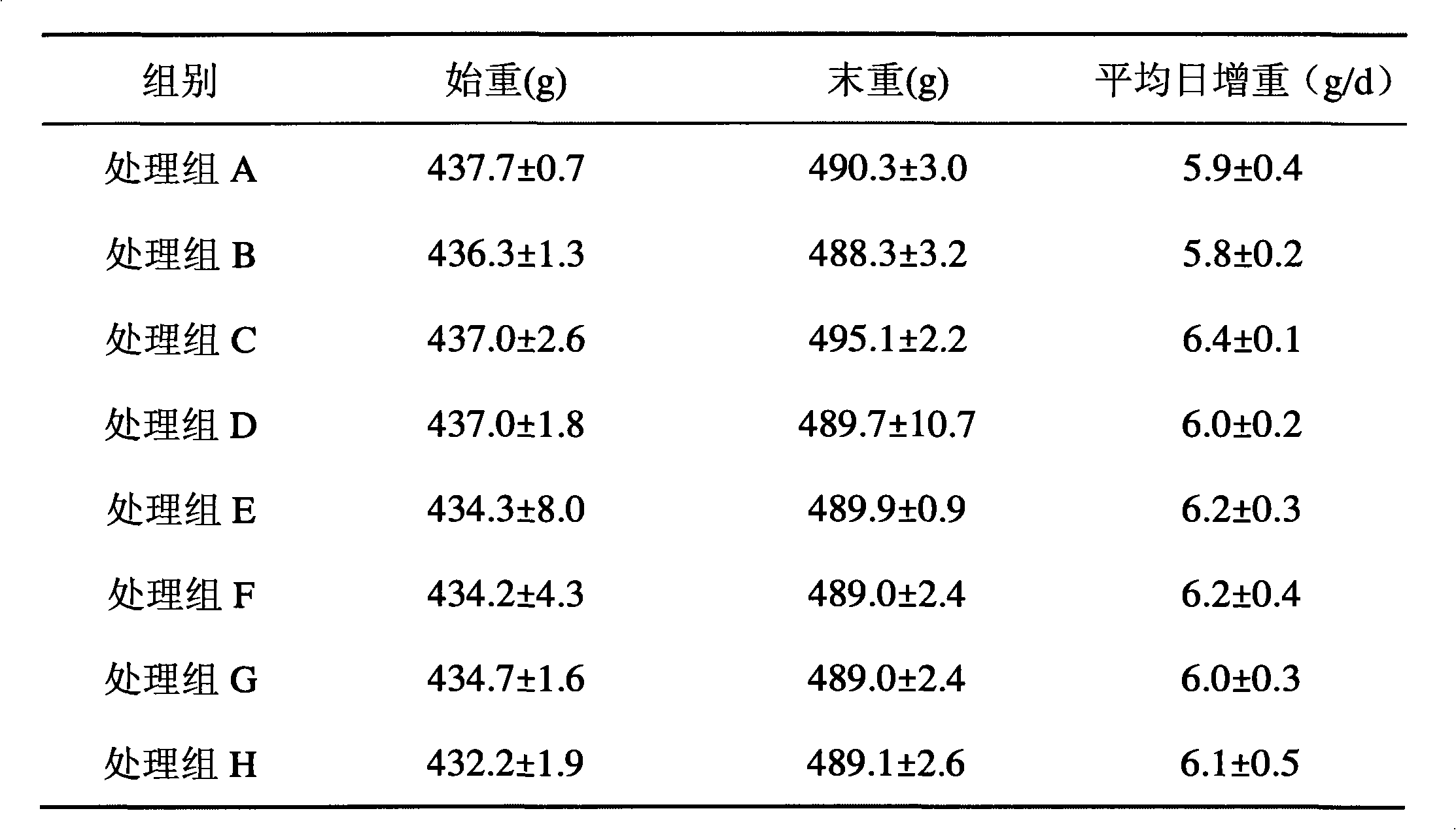

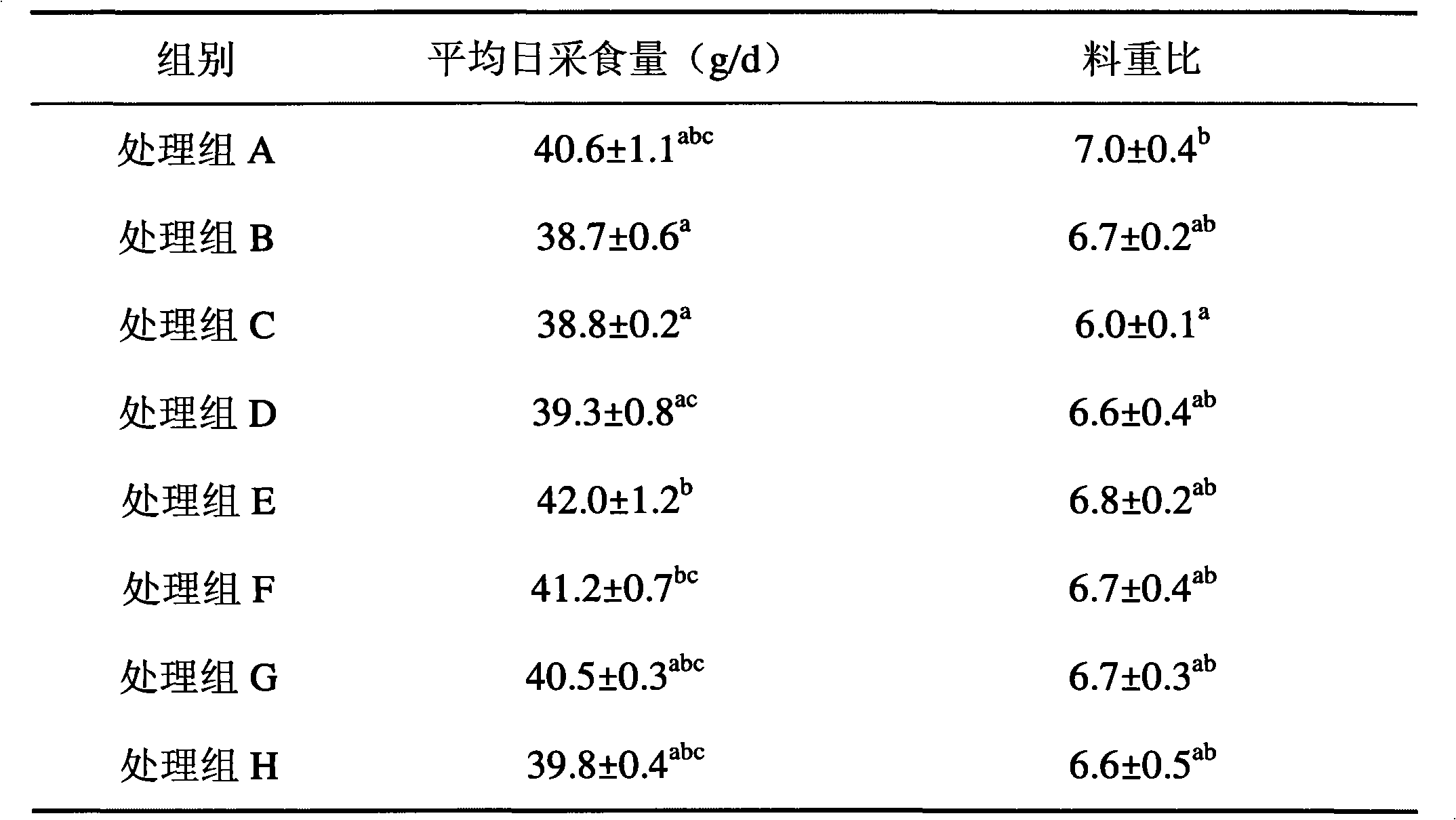

[0020] In order to explore the optimal protein level and energy level of fattening meat pigeon compound feed and test its effect on the growth of meat pigeons, experiments were carried out at the breeding base of Beiled Economic Development Co., Ltd. in Zhaoqing City, Guangdong Province. In the experiment, 1152 22-day-old healthy pigeons were randomly divided into 8 treatment groups, each treatment group had 3 replicates, and each replicate had 48 pigeons. The test adopts 2×4 factorial design, that is, the crude protein level is 19% and 20%; the metabolizable energy is 11.91MJ / kg, 12.12MJ / kg, 12.33MJ / kg, and 12.54MJ / kg respectively. , A-H represent 8 treatment groups respectively, the test period is 9 days, and the average daily gain, average daily feed intake and feed-to-weight ratio are counted after the test.

[0021] The present invention is further explained below in conjunction with the examples, but the examples do not limit the present invention in any form.

[0022] ...

Embodiment 2

[0037] Weigh the following raw materials in kilograms: corn 115.8, soybean meal 82.8, wheat 37.5, shell powder 3.8, soybean oil 6, premix 2.5, calcium hydrogen phosphate 1, salt 0.75; the premix provides per kilogram of compound feed: VA 2700~3240IU, VD 3 400~480IU, VE 10~12, VK 0.5~0.6mg, VB 1 1.8~2.2mg, VB 2 7.2~8.6mg, pantothenic acid 10~12mg, niacin 27~32.4mg, pyridoxine 3~3.6mg, biotin 0.15~0.18mg, choline 1300~1560mg, folic acid 0.55~0.66mg, VB 12 0.009~0.01, copper 8~9.6mg, iron 0.35~0.42mg, manganese 60~72mg, zinc 40~48mg, selenium 0.15~0.18mg. After the above raw materials are weighed, put them into a large crushing and mixing equipment for crushing and mixing. The premixed material is added after mixing other raw materials for a period of time to make powdery compound feed for fattening meat pigeons, and then extruded at a temperature of 85°C. Dry the feed pellets at a temperature of 80°C and pack them after cooling.

Embodiment 3

[0039] Weigh the following raw materials in kilograms: corn 91.5, soybean meal 80, wheat 62.5, shell powder 4, soybean oil 8.25, premix 2.5, calcium hydrogen phosphate 0.75, salt 0.5; the premix provides per kilogram of compound feed: VA 2700~3240IU, VD 3 400~480IU, VE 10~12, VK 0.5~0.6mg, VB 1 1.8~2.2mg, VB 27.2~8.6mg, pantothenic acid 10~12mg, niacin 27~32.4mg, pyridoxine 3~3.6mg, biotin 0.15~0.18mg, choline 1300~1560mg, folic acid 0.55~0.66mg, VB 12 0.009~0.01, copper 8~9.6mg, iron 0.35~0.42mg, manganese 60~72mg, zinc 40~48mg, selenium 0.15~0.18mg. After the above raw materials are weighed, put them into a large crushing and mixing equipment for crushing and mixing. The premixed material is added after mixing other raw materials for a period of time to make powdery compound feed for fattening meat pigeons, and then extruded at a temperature of 85°C. Dry the feed pellets at a temperature of 80°C and pack them after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com