Power-collecting conversion power supply device

A power supply device and kinetic energy technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of fear of potential safety hazards, difficult production technology, huge collection device, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

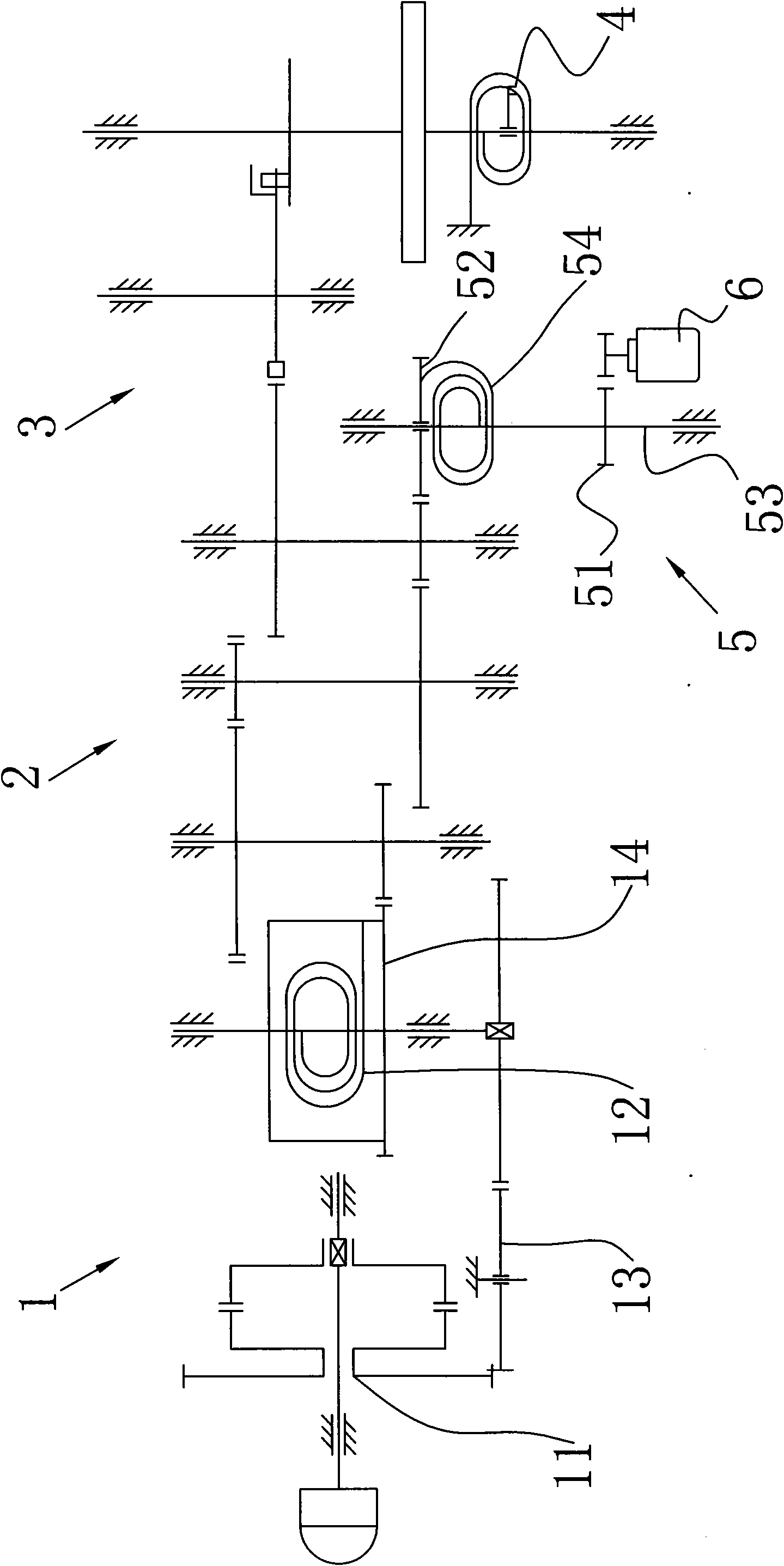

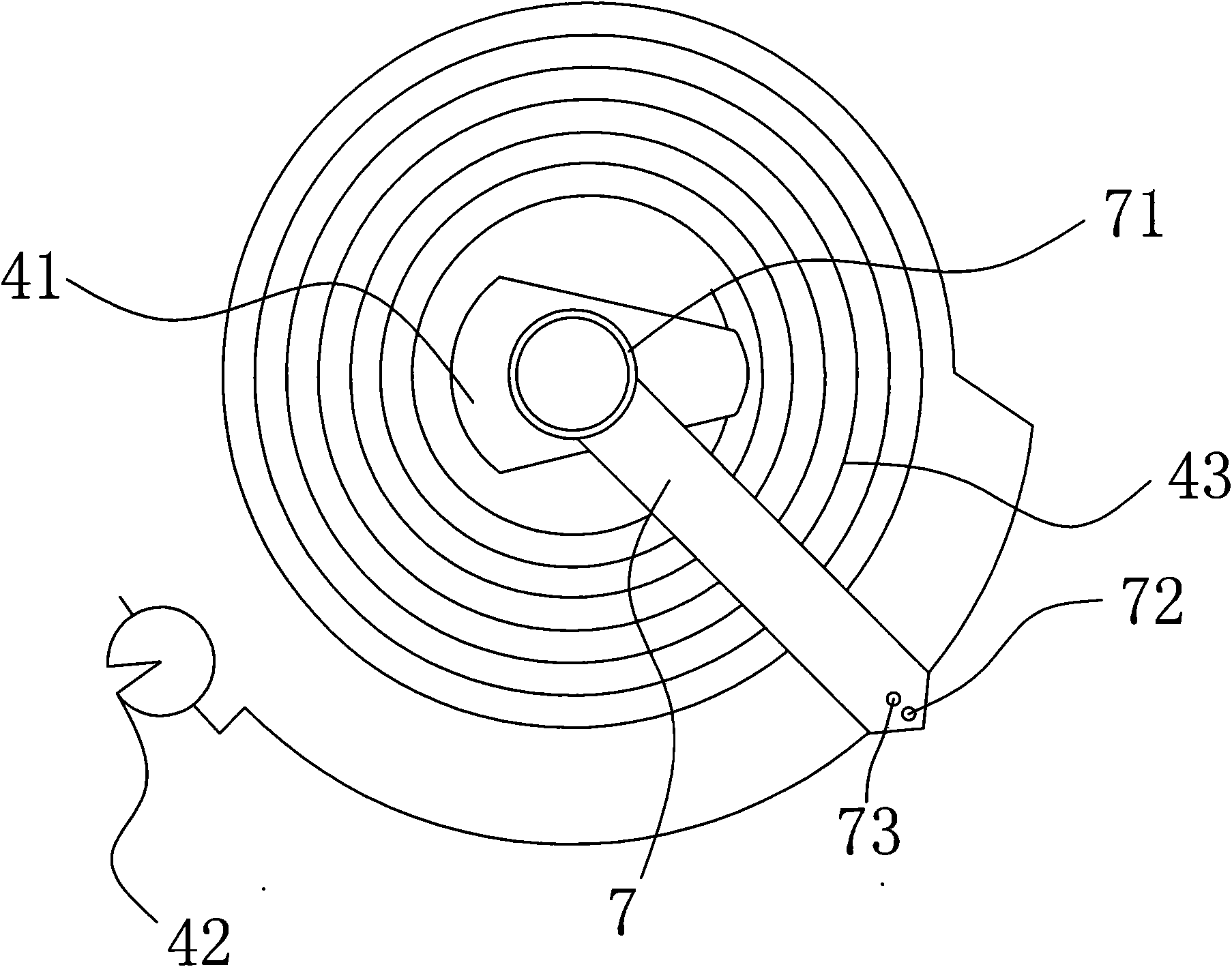

[0011] From figure 1 It can be seen that the present invention includes a kinetic energy collection and storage mechanism 1 , a transmission mechanism 2 , an escapement mechanism 3 , a speed regulating mechanism 4 , an incoherent kinetic energy collection and conversion mechanism 5 , and a generator 6 . The kinetic energy collection and storage mechanism 1, the transmission mechanism 2, the escapement mechanism 3, and the speed regulating mechanism 4 are connected sequentially, the input end of the incoherent kinetic energy collection and conversion mechanism 5 is connected with the transmission mechanism 2, and the output end of the incoherent kinetic energy collection and conversion mechanism 5 is connected to the generator 6, the non-coherent collection and conversion mechanism 5 includes a shaft 53, a sub-gear 51 fixed on the shaft 53, a rotatable female gear 52, and a hairspring 54. One end of the hairspring 54 is connected to the shaft 53, and the other end is connected t...

specific Embodiment 2

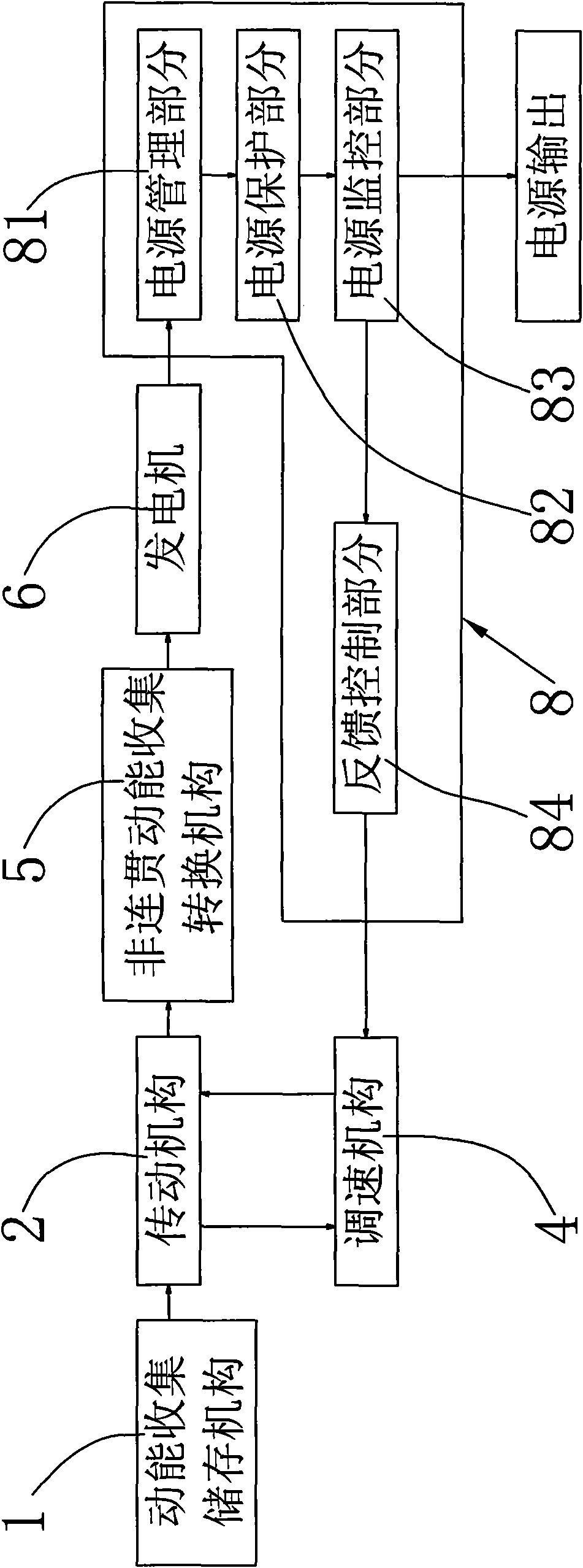

[0015] From image 3 It can be seen that the present invention can also connect a feedback control power supply system 8 at one end of the speed regulating mechanism 4 and the generator 6. This system mainly realizes the automatic adjustment of power. Through feedback control, the power consumption of the system can be adjusted in real time. , to achieve the effect of energy saving. The system includes a power management module 81, a power protection module 82, a power monitoring module 83 and a feedback control module 84 connected in sequence, the power management module 81 is connected with the generator 6, the feedback control module 84 is connected with the speed regulating mechanism 4, and the generator 6 The emitted power is output through the power monitoring module 83 . All the modules in the above-mentioned feedback control power supply system 8 can adopt modules in the prior art.

[0016] The main functions of the power management module 81 are rectification and vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com