High-efficiency double-layer internal-reflecting fluorescent tube

A fluorescent tube and double-layer technology, applied in the field of fluorescent tubes, can solve the problems of low lifespan and low luminous flux, and achieve the effects of increasing lifespan, increasing luminous flux, and improving the utilization rate of luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

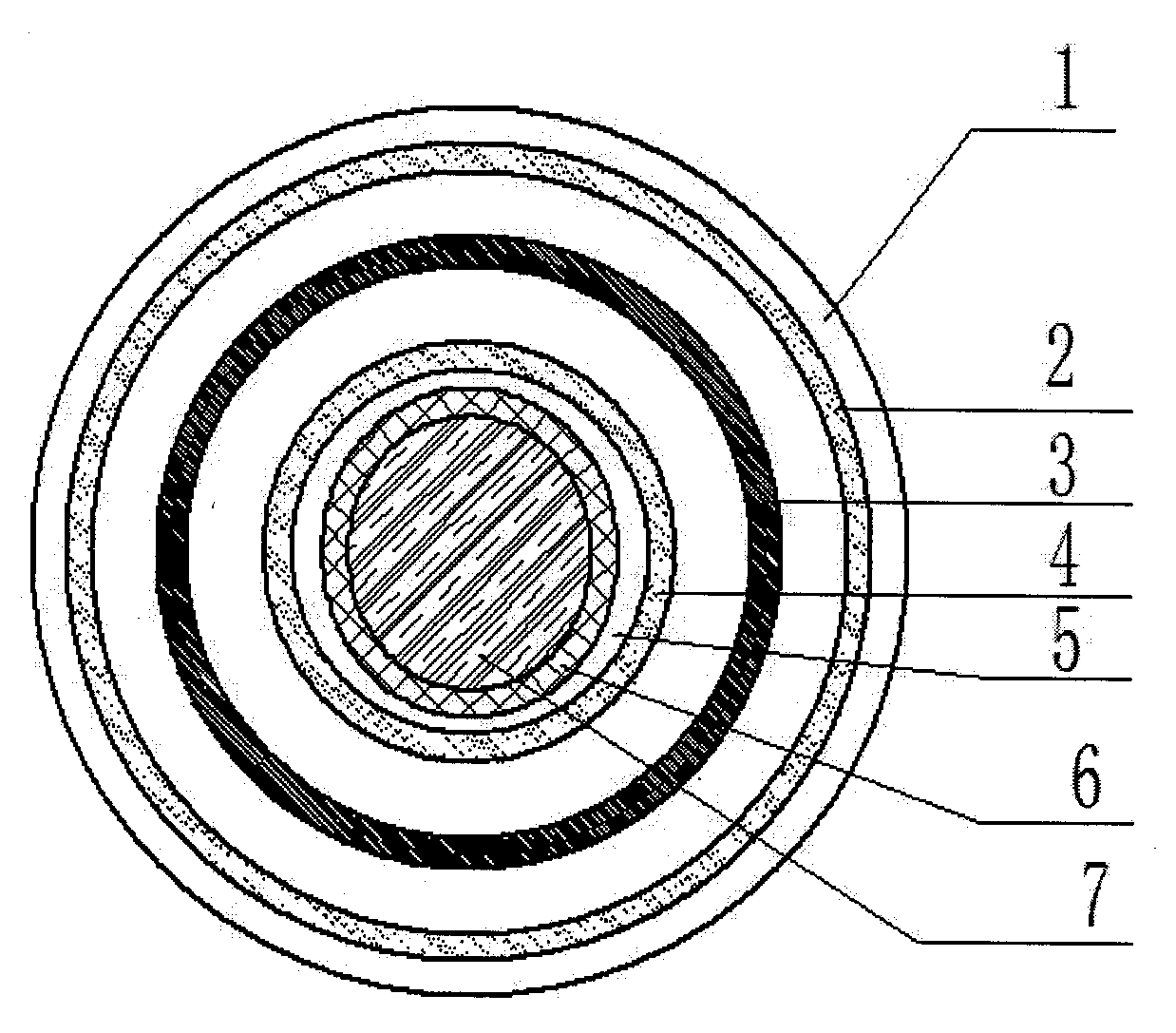

[0006] according to figure 1 The present invention shown is composed of double-layer lamp tubes, the outer wall of the inner glass tube and the inner wall of the outer glass tube are coated with pure tricolor phosphor powder, and the effective luminous area is increased by 50%. The evacuated space of the fluorescent tube is the inner wall of the outer layer and the outer wall of the inner layer. The space is reduced, the power is reduced, and the current is also proportionally reduced, and the light efficiency is increased by about 30%. The light cannot be emitted, which reduces the luminous flux. If the thickness of the powder coating on the inner wall of the outer lamp tube is reduced by half, the light transmittance will increase, and the corresponding luminous flux will also increase. The inner glass tube is equipped with thermal insulation material, which can ensure the temperature of the fluorescent tube and avoid the power increase of the fluorescent tube due to the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com