Circulating fluidized bed sulfur fixation ash aerated concrete and preparation method thereof

A circulating fluidized bed and air-entrained concrete technology, which is used in the manufacture of tools, ceramic products, solid waste management, etc. environment, reducing large-scale stacking, and the effects of excellent finished product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

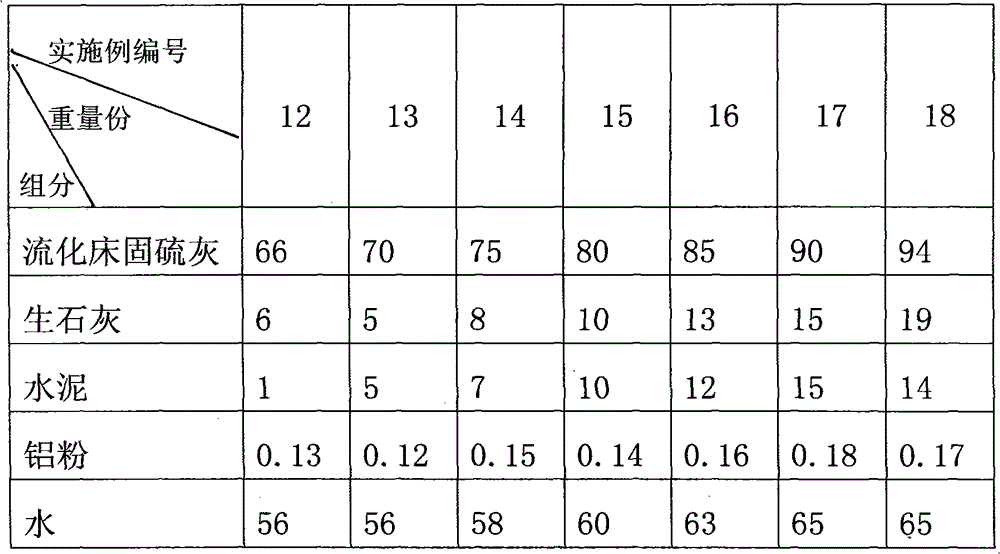

Examples

Embodiment 1

[0035] A method for preparing a circulating fluidized bed sulfur-fixed ash aerated concrete, comprising the following steps:

[0036] a. Grinding: Grinding the sulfur-fixed ash (equipment in the prior art such as ball mill, vibrating mill, jet mill, etc.) to a particle size of 0.08mm and a sieve residue of 4.3-7.9%, with a median particle size of 10.394-13.928um ;

[0037] B. Weighing: Weigh quicklime, air-entraining agent aluminum powder 0.14% (that is, the consumption of aluminum powder is 0.14% of other raw materials weight) by 12% of sulfur-fixed ash (percentage by weight, the same below), water and other raw materials The ratio by weight is 0.59; the total amount of powder prepared in this embodiment is 1010g, and the specific data are weighed as follows:

[0038] Fluidized bed sulfur-fixed ash 900g; quicklime 110g; aluminum powder 1.4g; water 595g;

[0039] c. Stirring: first put the sulfur-fixed ash and quicklime powder into the mixer and stir for 1mim. After the powd...

Embodiment 2

[0046] A circulating fluidized bed sulfur-fixed aerated concrete is composed of fluidized bed sulfur-fixed ash, quicklime, aluminum powder and water, and the specific data are weighed as follows:

[0047] Fluidized bed sulfur-fixed ash 900g; quicklime 110g; aluminum powder 1.3g; water 590g;

[0048] The preparation method and steps of the air-entrained concrete are the same as in Example 1;

[0049] Measure the strength of the present embodiment air-entrained concrete to be 4.18MPa, and the density is 623kg / m 3 .

Embodiment 3

[0051] A circulating fluidized bed sulfur-fixed aerated concrete is composed of fluidized bed sulfur-fixed ash, quicklime, aluminum powder and water, and the specific data are weighed as follows:

[0052] Fluidized bed sulfur-fixed ash 900g; quicklime 110g; aluminum powder 1.4g; water 590g;

[0053] The preparation method, steps and curing conditions of the air-entrained concrete are the same as in Example 1;

[0054] Measure the strength of the air-entrained concrete of this embodiment to be 3.81MPa, and the dry density is 617kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com