Flexible waist for robot

A robot and flexible technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of inflexible movement, poor controllability, and few degrees of freedom, and achieve the effect of expanding the scope of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

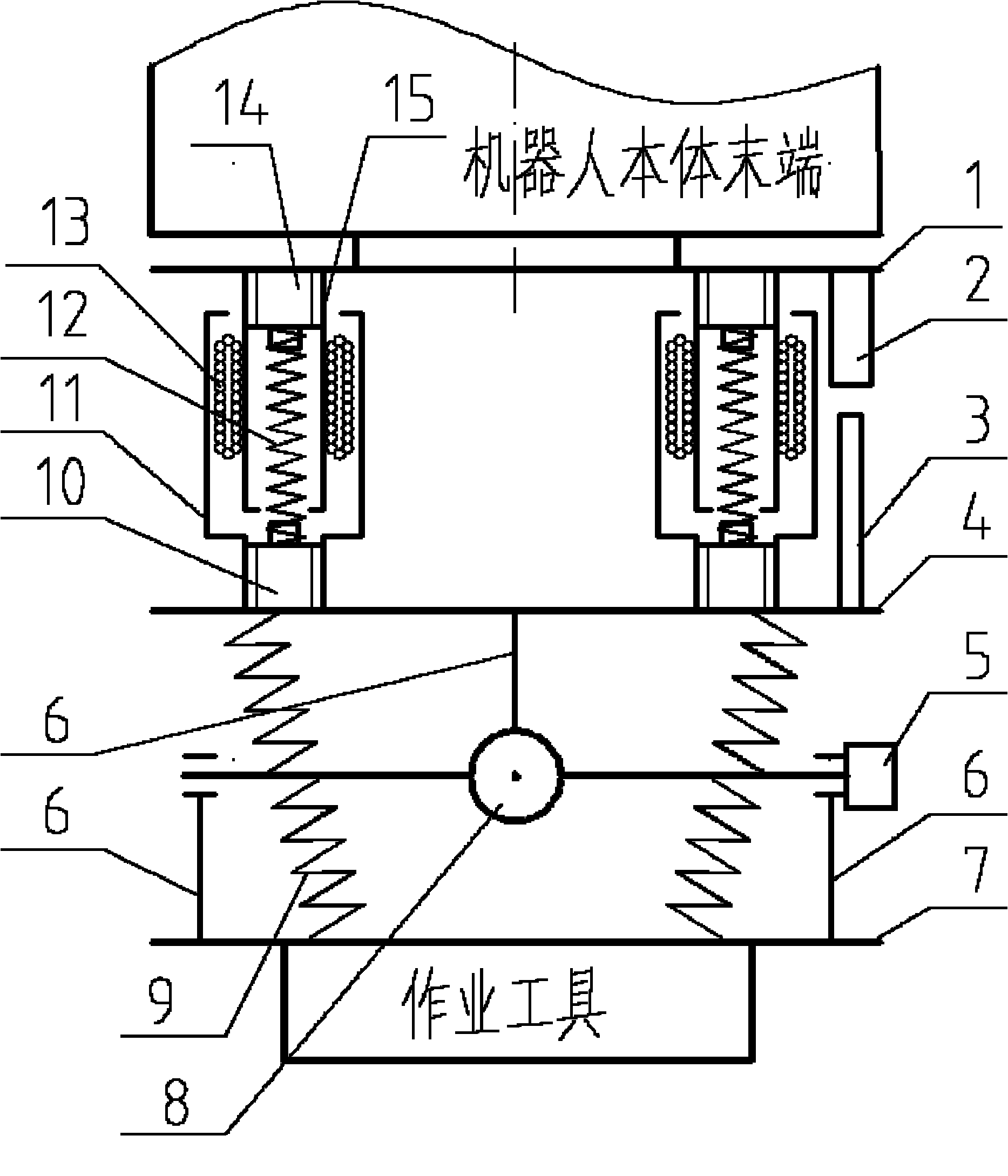

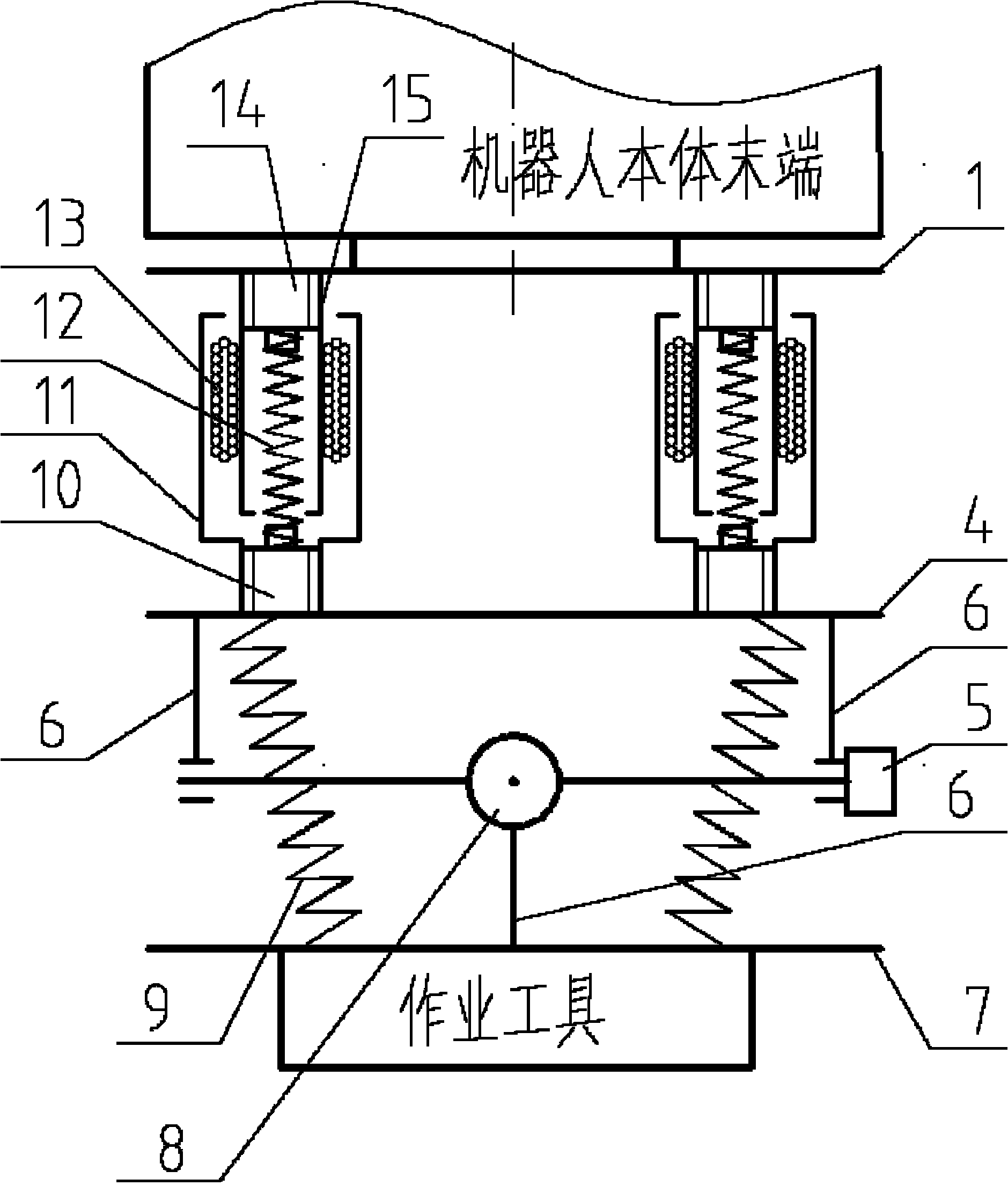

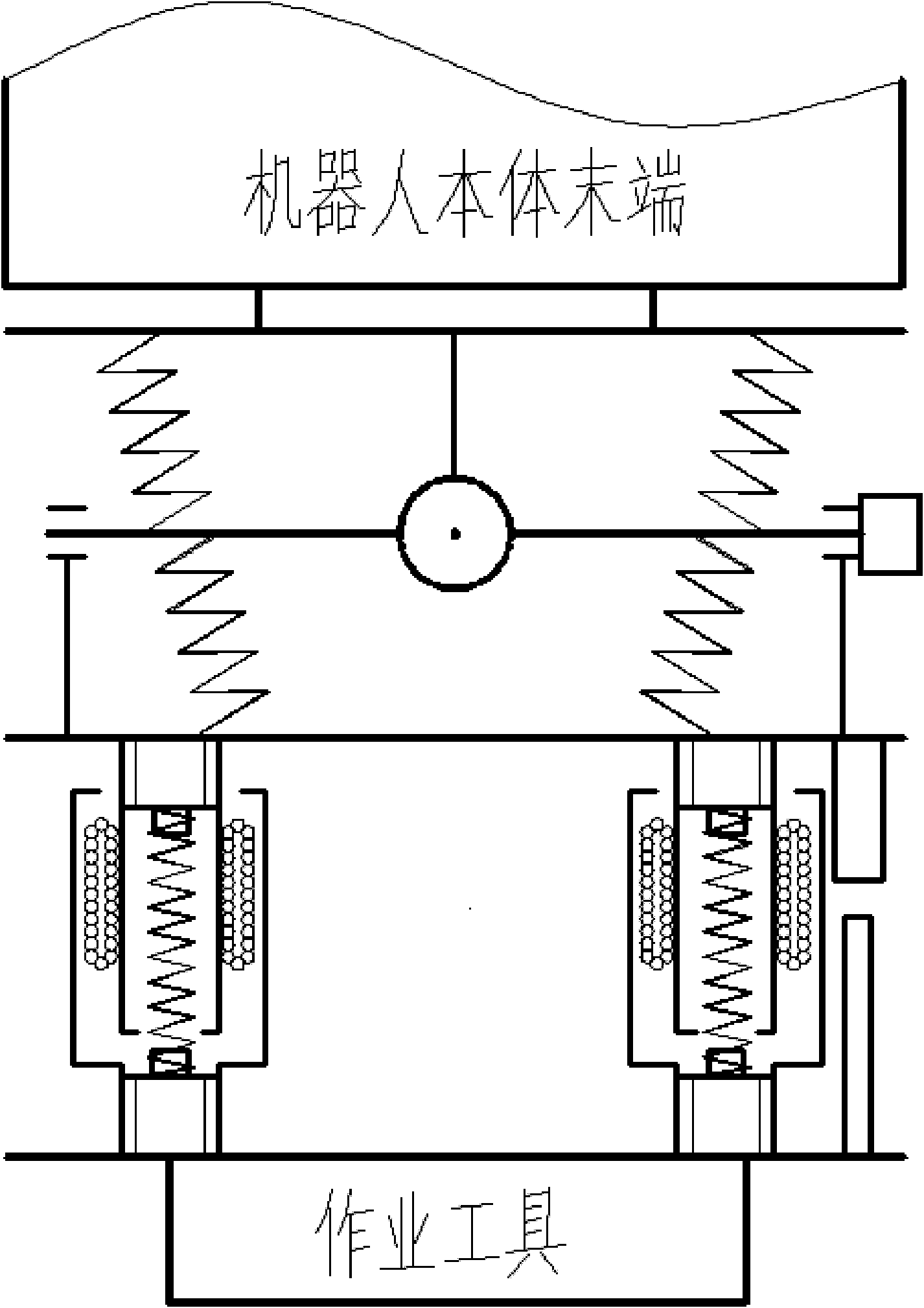

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The wrist of the present invention includes a swing part, a moving part, a fixed plate, a connecting plate, a mounting plate, a displacement sensor and an angle sensor, and it has three degrees of freedom, wherein the moving part can move in one direction, The swinging part can realize swinging in two directions, and the specific structure is as follows: figure 1 , figure 2 as shown, figure 1 and figure 2 The cross-sectional diagrams of the wrist in the front view and the left view are respectively.

[0028] The moving part has a supporting sleeve structure, and the supporting sleeve structure has an upper supporting sleeve 15 , a lower supporting sleeve 11 , a linear bearing 13 , adjusting screw plugs 14 , 10 and a spring 12 . The fixed plate 1 is fixed at the end of the robot body, the upper support sleeve 15 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com