Welding fixture tool of aluminum alloy battery tank body for electric automobile

A technology for electric vehicles and tooling, applied in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficulty, welding deformation, and inability to install batteries, achieve high positioning accuracy, reduce deformation, and ensure welding accuracy. and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

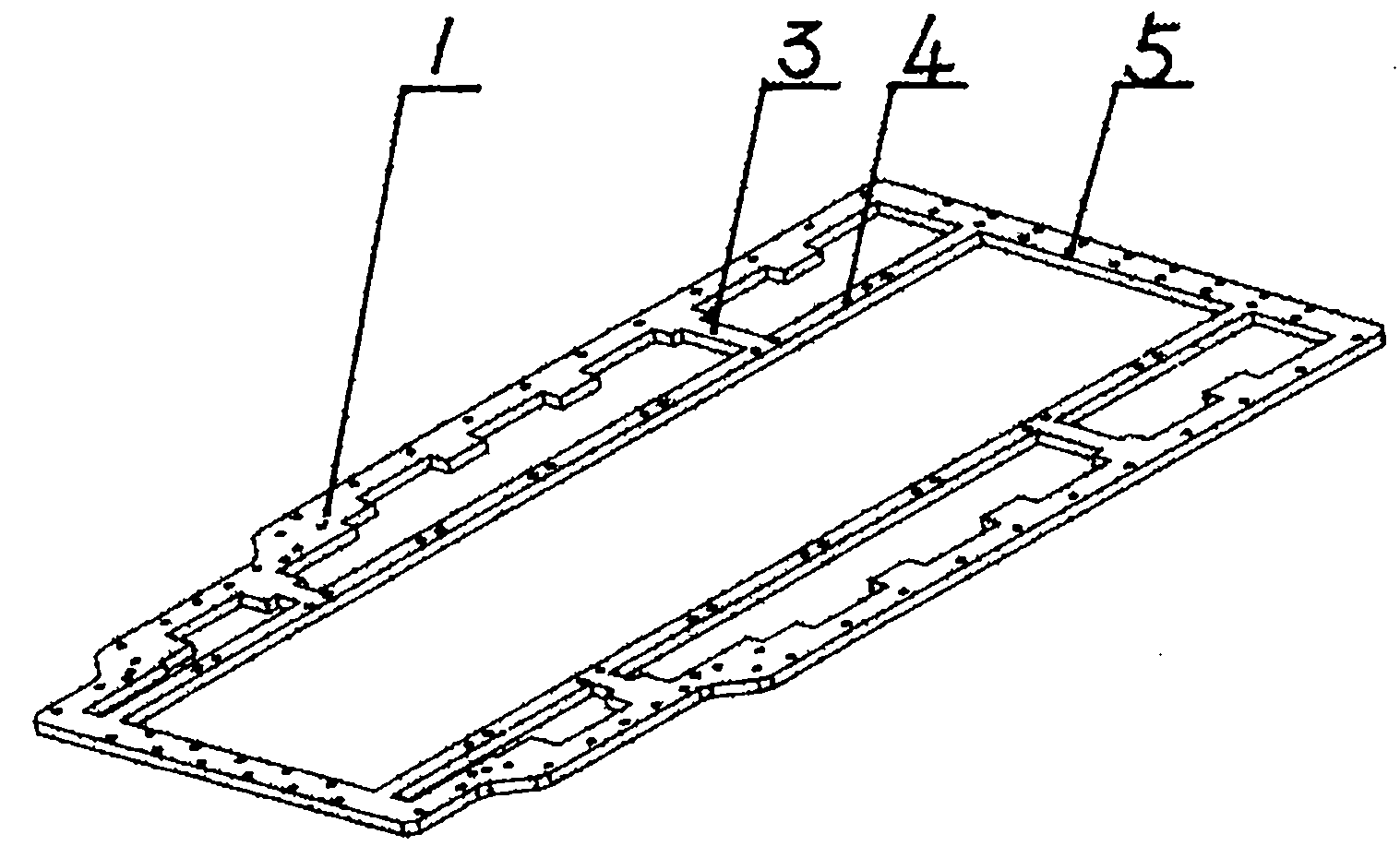

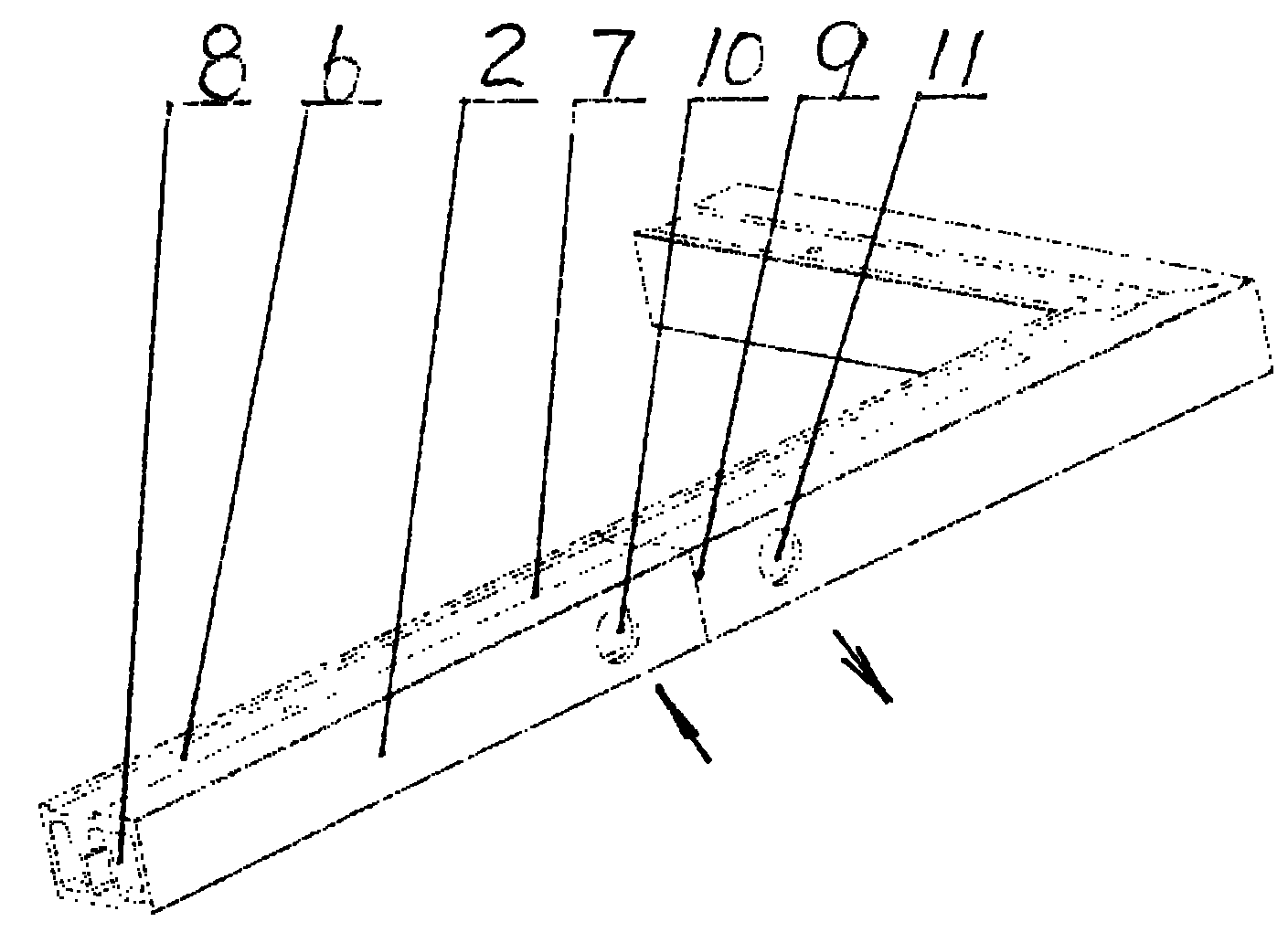

[0008] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are cited hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to Figure 1-Figure 5 .

[0009] like Figure 1-Figure 3 As shown: the present invention includes an upper tooling frame 1 and a lower tooling frame 2, and the upper tooling frame 1 is provided with a cross brace 3, a longitudinal beam 4, and an A threaded hole 5, and the cross brace 3 and the longitudinal beam 4 are integrated with the upper tooling frame 1 ; The lower tooling frame 2 is provided with a mounting groove 6, a B threaded hole 7, a cooling channel 8, a baffle plate 9, a cooling water inlet 10 and a cooling water outlet 11; the lower tooling frame 2 is provided with a cooling channel 8 composed of three cavities The baffle plate 9 arranged on one side of the lower tooling frame 2 divides the annular cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com