Two-stage horizontal type mixing device with multiple dispersion system and method thereof

A technology of a dispersing system and a mixing device, which can be used in mixing methods, mixers with rotary stirring devices, mixers, etc., can solve problems such as the generation of agglomerates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] A two-stage horizontal mixing device includes the following parts:

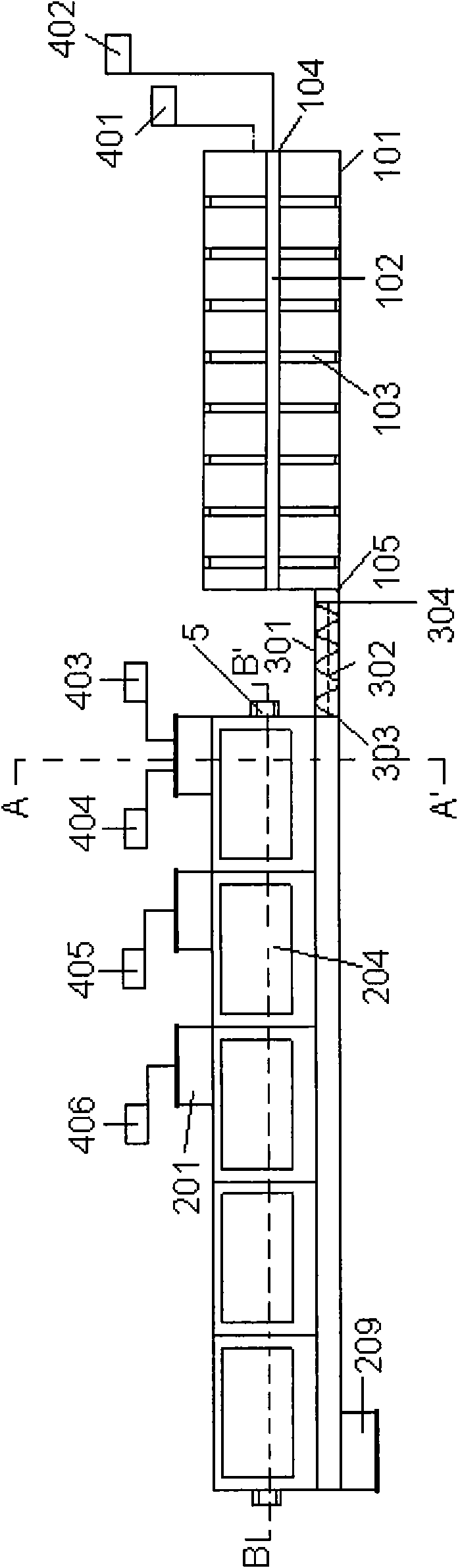

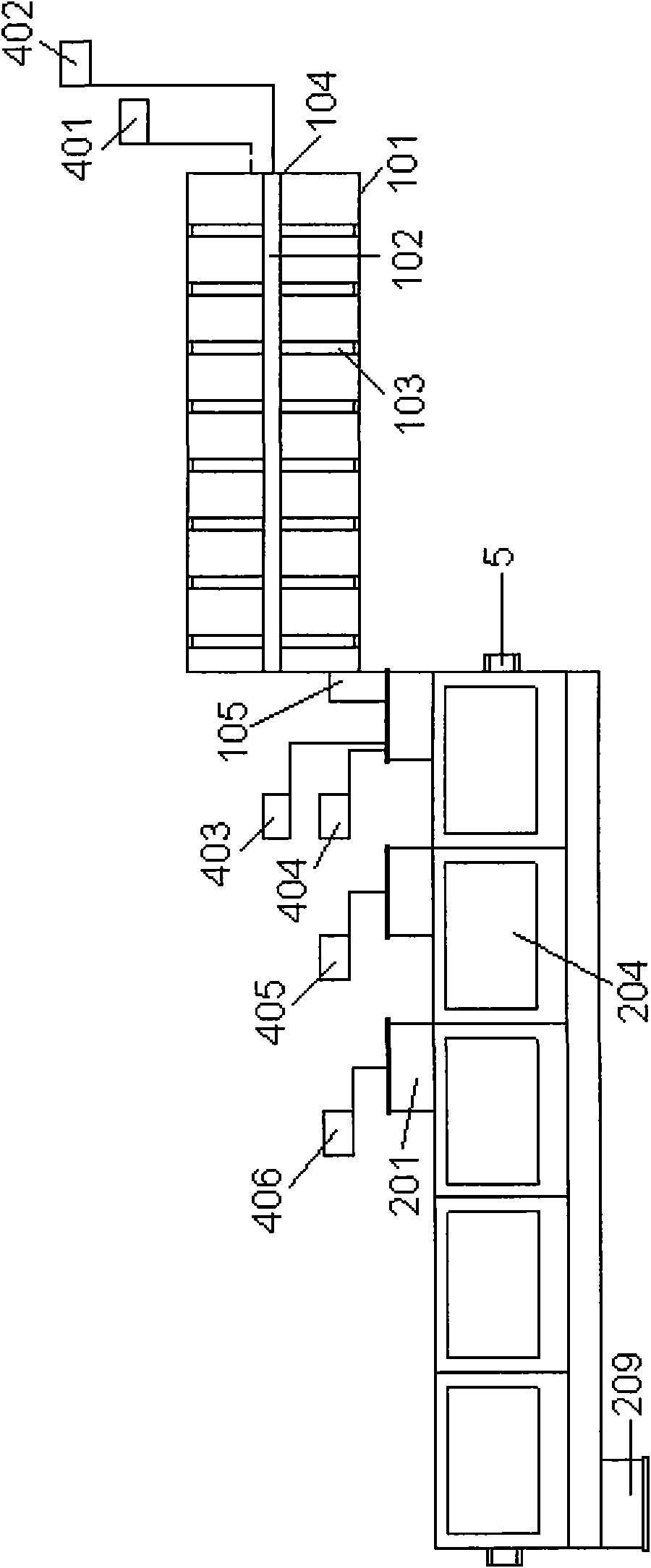

[0110] according to Figure 1a and Figure 1b :

[0111] The two-stage horizontal mixing device includes a premixing system 1 , a mixing system 2 , a packing system 4 , a shaft system 5 , a first stirring system 6 , a second stirring system 7 and a propulsion system 10 .

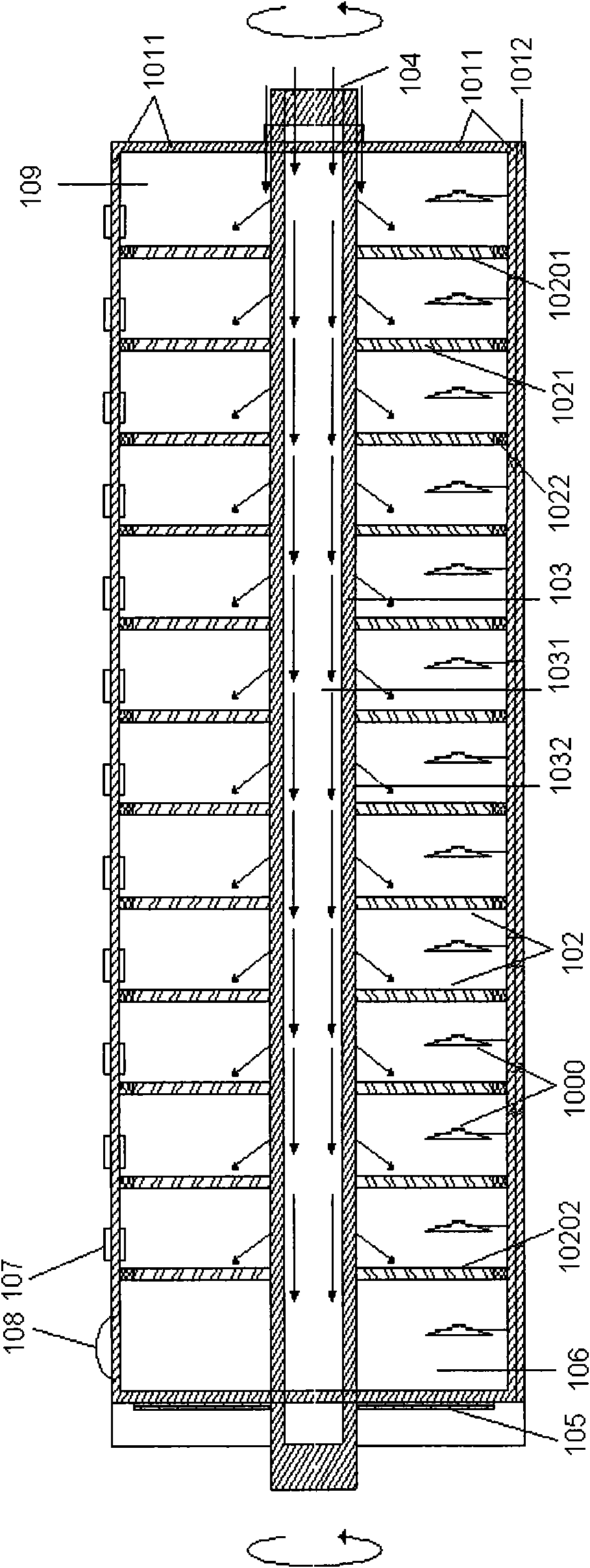

[0112] The pre-mixing system 1 is connected to the mixing system 2 through the delivery system 3, or directly connected to the mixing system 2. according to figure 2 and image 3 :

[0113] The premixing system 1 is a cylindrical horizontal premixing device formed by a housing 101 and centered on a horizontal rotating shaft 103, which contains a group of trays connected to the rotating shaft 103 and rotating therewith. The trays are further divided into a first tray group and a second tray group.

[0114] The trays of the first tray group and the second tray group are distributed alternately, and a separate mixing chamber is f...

Embodiment 2

[0203] Adopt following technical parameter to improve embodiment one:

[0204]The ratio of the radii of the housing 101 , the first cavity shell 202 and the second cavity shell 203 is 5:1:1.

[0205] The radius ratio of the first chamber shell 202 and the second chamber shell 203 is 1:1.5.

[0206] The speed ratio of the first rotating shaft 501, the second rotating shaft 502 and the rotating device 703 is 2:1:1.5

Embodiment 3

[0208] Adopt following technical parameter to improve embodiment one:

[0209] The ratio of the radii of the housing 101 , the first cavity shell 202 and the second cavity shell 203 is 6:1:1.

[0210] The radius ratio of the first chamber shell 202 and the second chamber shell 203 is 1:2.

[0211] The rotational speed ratio of the first rotating shaft 501 , the second rotating shaft 502 and the rotating device 703 is 4:1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com