Pulse clarification tank

A clarifier and pulse technology, applied in sedimentation tanks, chemical instruments and methods, separation methods, etc., can solve the problems of small rising flow rate of clean water, large tank area, low sludge concentration, etc., to improve hydraulic load and simple maintenance. , the effect of reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

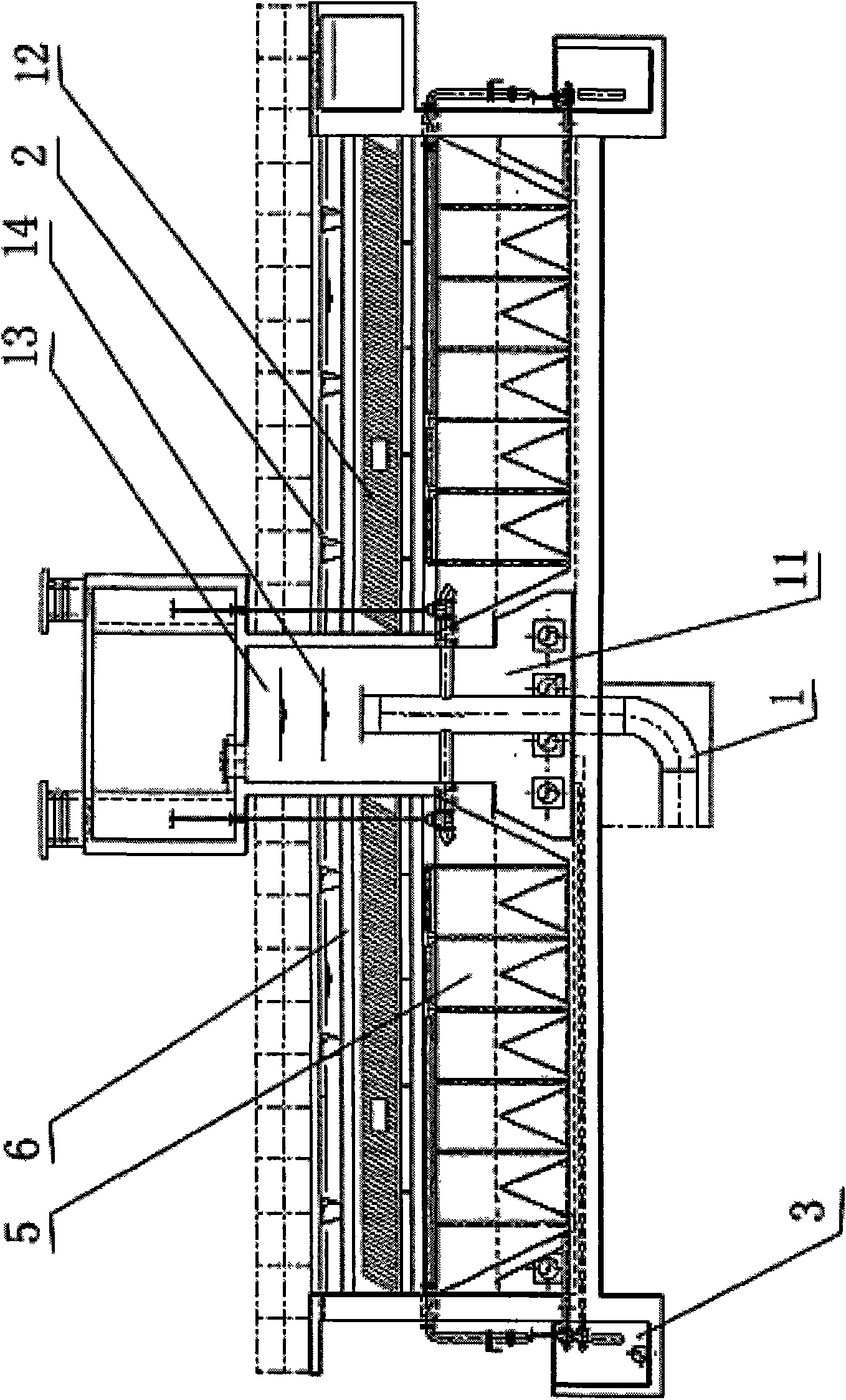

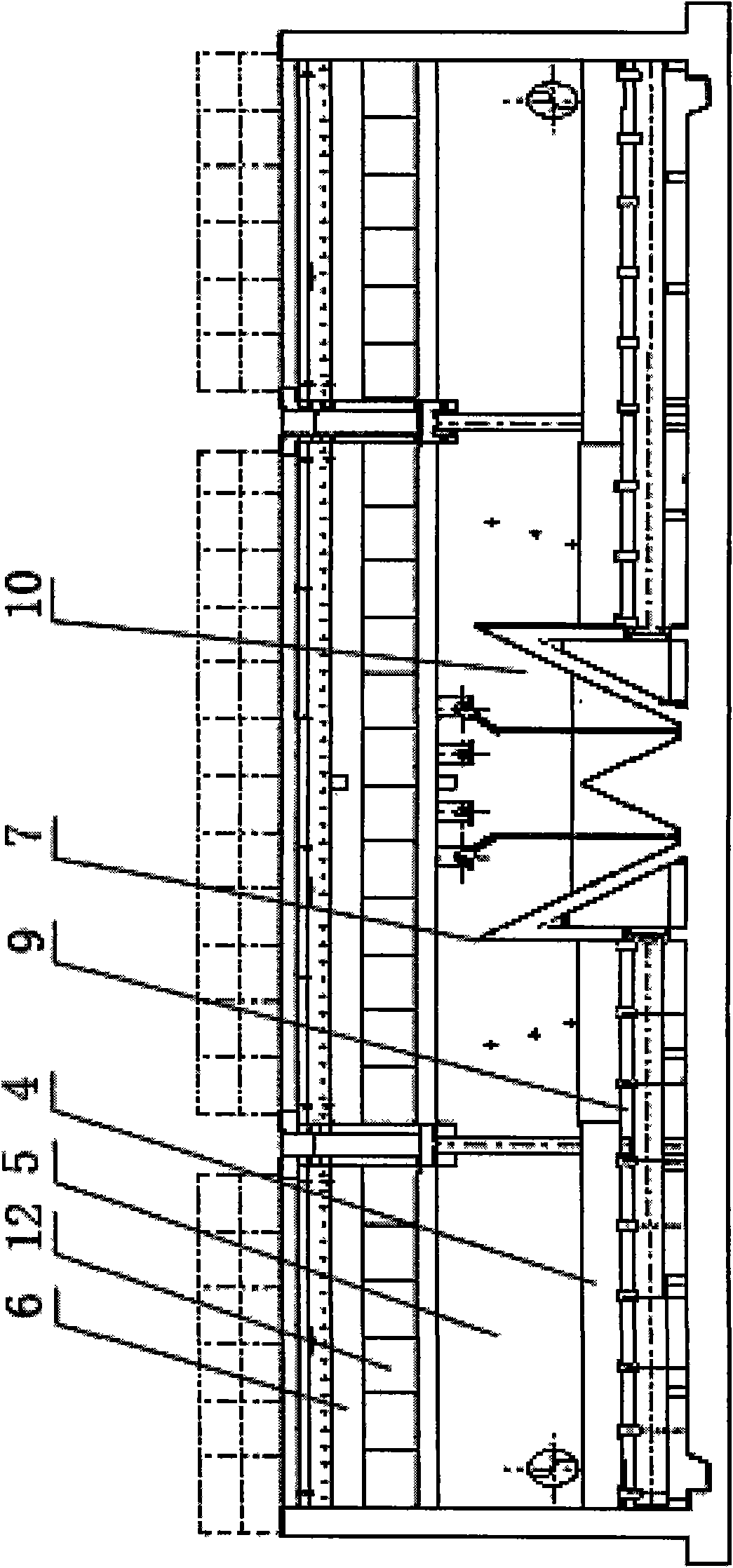

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

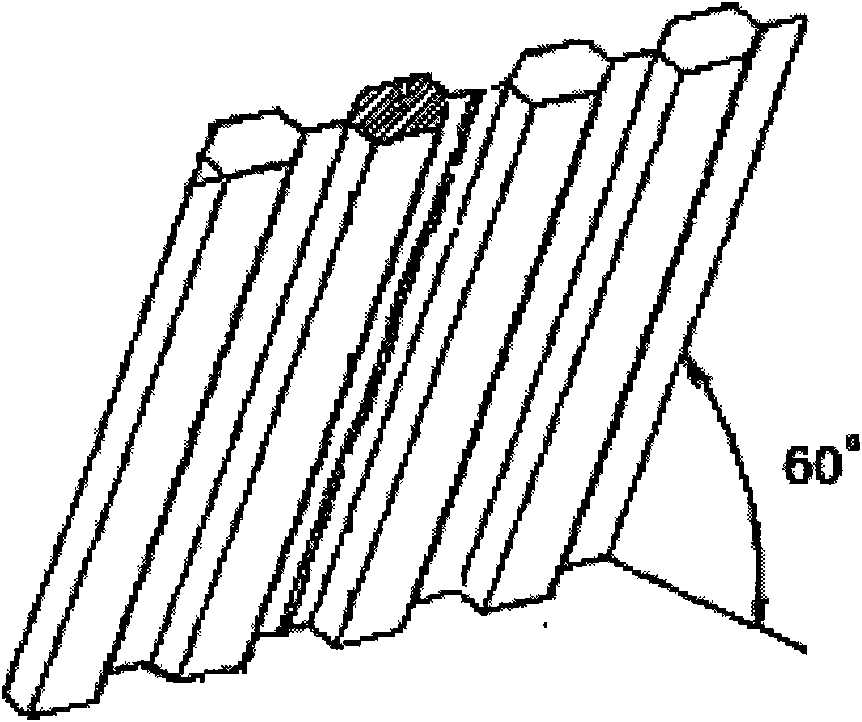

[0021] Such as Figure 1-Figure 3 As shown, the present invention includes a pulse generator made up of a raw water inlet pipe 1, a water inlet chamber, a blower, and a vacuum breaking valve, and a raw water distribution pipe 9, a clarified water collection tank 2, a mud discharge ditch 3, a rectifying plate 4, and a clarifying The pool body composed of the pool and the sludge thickening chamber 10. The clarifiers are arranged in square, circular or rectangular shapes. The water inlet chamber is divided into an upper vacuum chamber 13 and a raw water distribution chamber 11 at the bottom. The top of the water inlet chamber is provided with a vacuum breaking valve (electric or pneumatic), and the top of the vacuum chamber 13 is provided with a blower connected to the outside atmosphere. The water inlet chamber is provided with a liquid level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com