Synchronous implanting mechanism and method of commutator megohmits

A technology of mica sheets and commutators, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of unsynchronized insertion of mica sheets, affecting the quality and speed of commutator assembly, and improve quality and speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

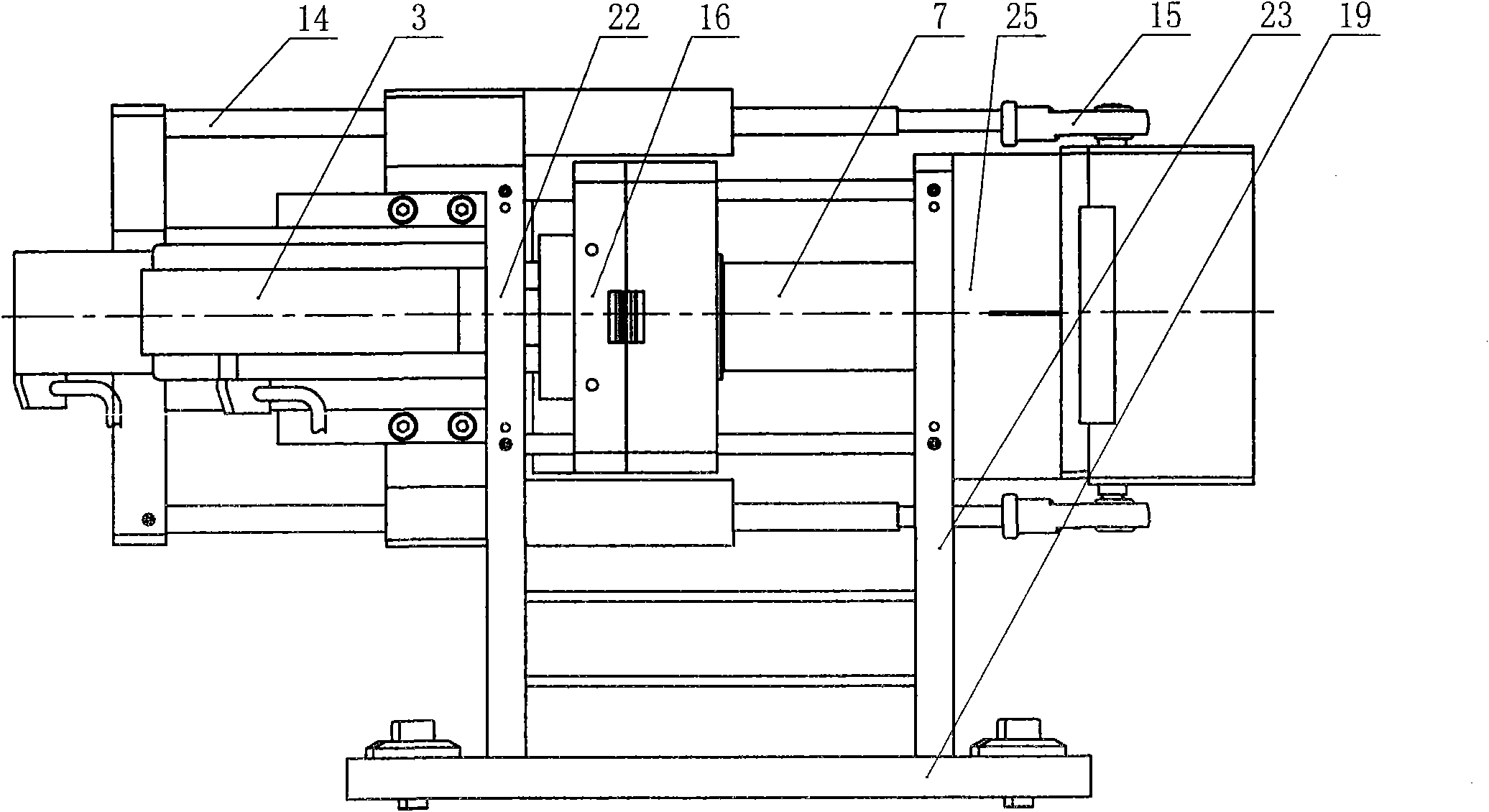

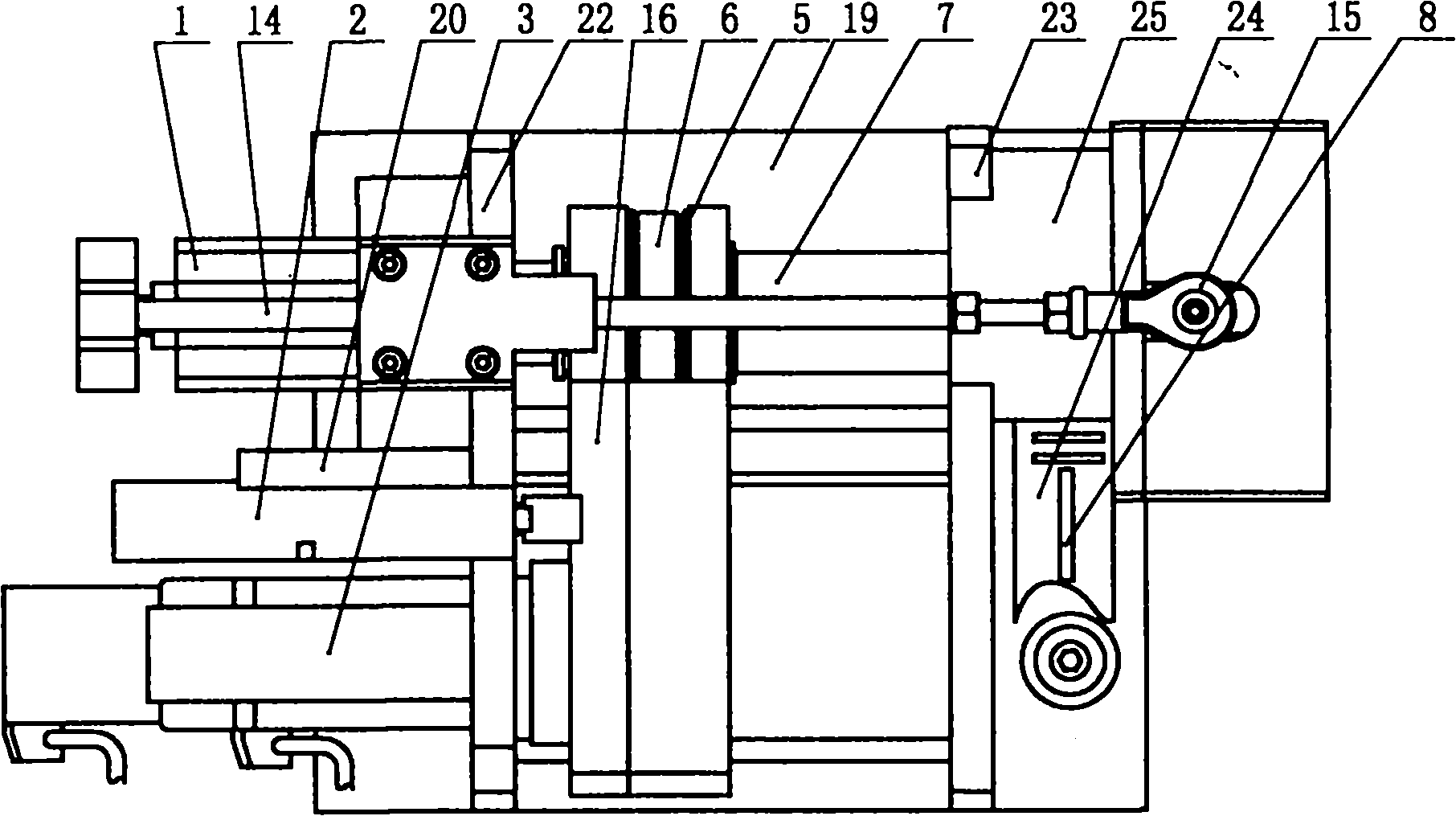

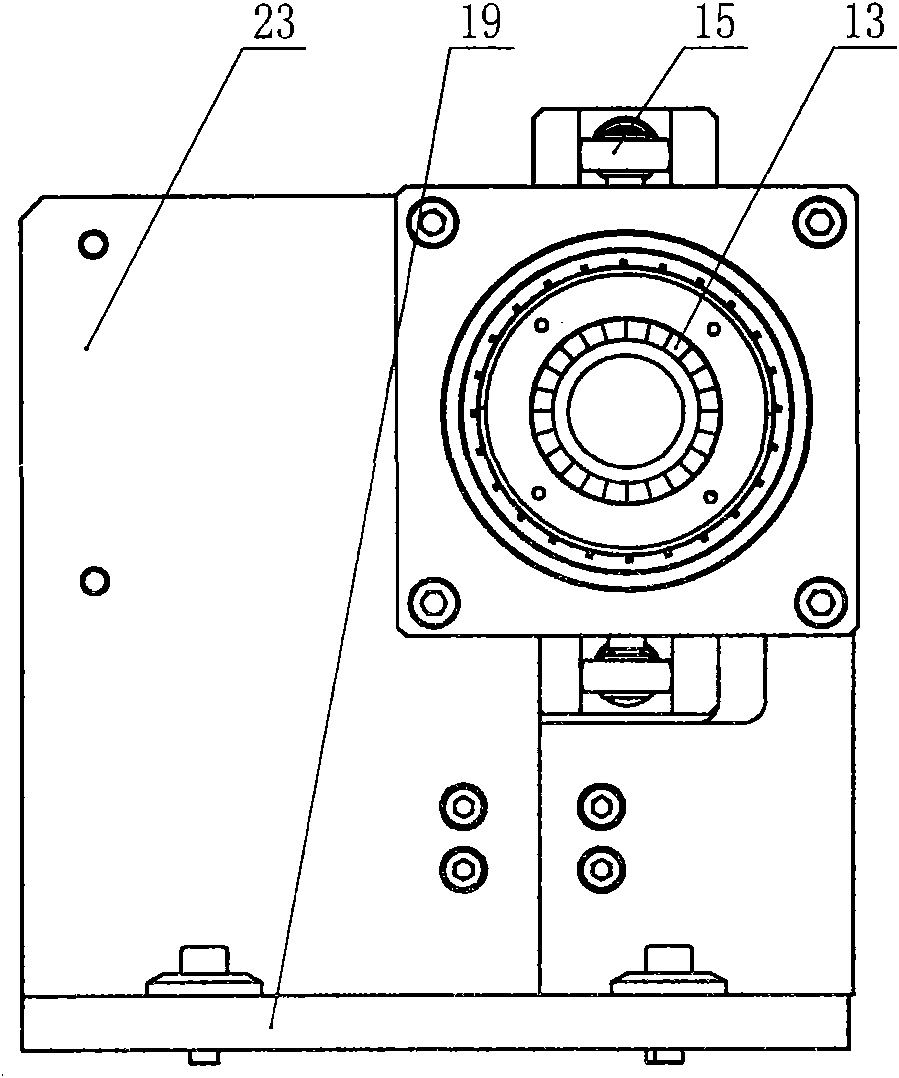

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0017] like Figure 1 to Figure 4 As shown, the present invention is applied to the synchronous implantation mechanism of the commutator mica sheet of the commutator mica sheet assembly machine, including a motor 3 (for a servo motor), a motor mount 16, and one end of the motor mount 16 is installed Slide bar 4 is arranged, and slide bar 4 overcoats have equal parts waiting for cover device 7, wait for cover device synchronous wheel 5 to be housed on equal parts cover device 7, wait for cover device synchronous wheel 5 to pass through synchronous belt 6 and motor synchronous wheel 17 on the motor Connected, the motor mounting base 16 is connected with the propulsion cylinder 2; the other end of the slide rod 4 is equipped with a combined sleeve 13, and the combined sleeve 13 is sequentially equipped with a sliding sleeve 9 and a pressure wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com