Discharge test device for distributed full online storage battery pack

A battery pack and discharge testing technology, applied in battery circuit devices, measuring electricity, current collectors, etc., can solve the problems of interruption accident, high risk and high cost, and achieve flexible and safe use, high degree of intelligence, and wide range of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

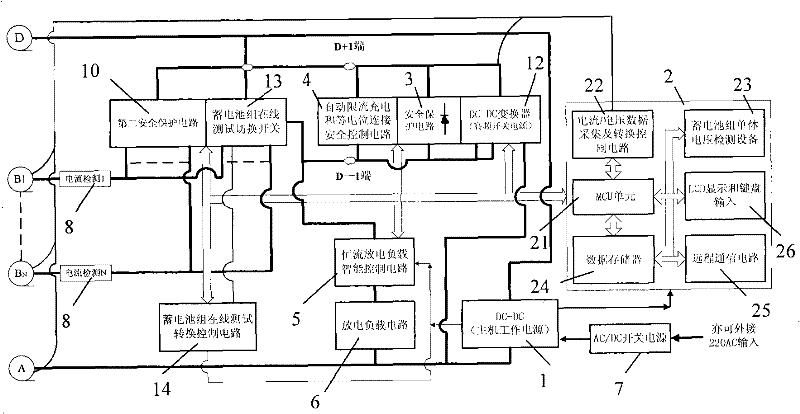

[0041] see figure 1 As shown, a distributed full-line battery pack discharge test equipment includes: a DC-DC host power supply 1, a control unit 2, a safety protection circuit 3, an automatic current-limited charging and equipotential connection safety control circuit 4 , a constant current discharge load intelligent control circuit 5, a discharge load circuit 6, a second safety protection circuit 10, a DC-DC converter 12, a battery pack online test switching switch 13, a battery pack online test conversion control circuit 14 . The control unit 2 further includes an MCU unit 21, and a current / voltage data acquisition and conversion control circuit 22 connected to the MCU unit 21, a battery unit voltage detection device 23, a data memory 24, and a remote communication circuit. 25. LCD display and keyboard input 26;

[0042] The safety protection circuit 3, the automatic current-limiting charging and equipotential connection safety control circuit 4, and the DC-DC converter 1...

Embodiment 2

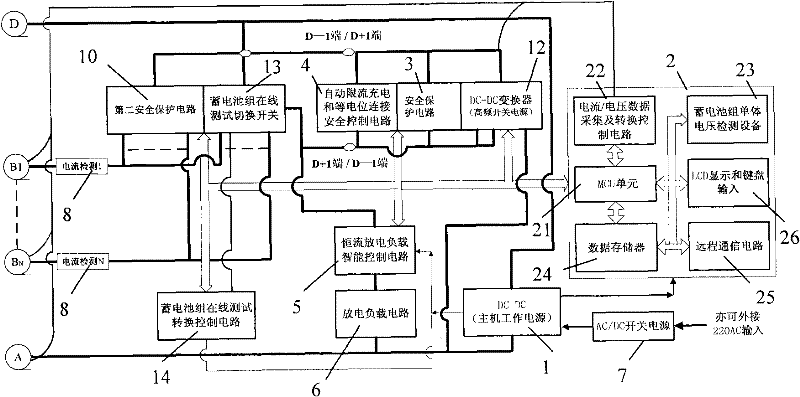

[0061] Such as figure 2 As shown, the distributed all-on-line battery pack discharge test equipment of this embodiment 2 is basically the same as the structure and connection terminals of the above-mentioned embodiment 1. The difference between the two is that in this embodiment 2, the DC-DC converter 12. DC-DC host power supply 1. The constant current discharge load intelligent control circuit 5 has the characteristics of forward and reverse polarity power supply. It can realize the best and safe operation mode, and is suitable for the discharge maintenance test of different positive and negative communication power supply online battery packs. Regardless of whether the working power supply is positive or negative grounding, when the device performs online maintenance tests, it only needs to operate the working ground terminal of the power supply connected to the side of the battery pack, which avoids the risk of short-circuiting the operation and grounding, and has the abil...

Embodiment 3

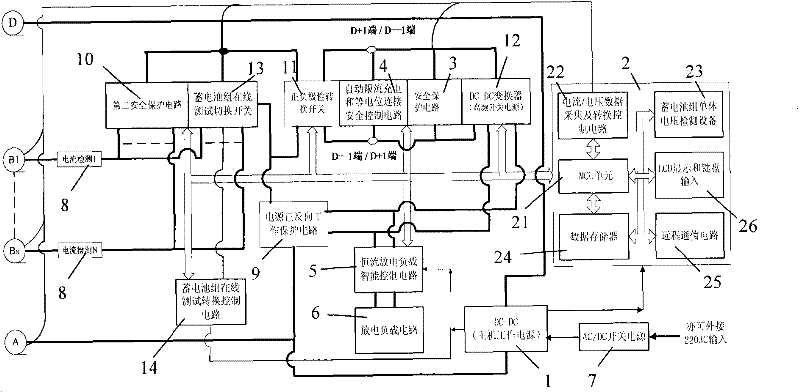

[0064] see image 3 , the third embodiment is a transformation of the second embodiment. Compared with the second embodiment, the difference between the two is that the distributed all-on-line battery pack discharge test equipment of the third embodiment also includes a forward and reverse power supply Polarity work protection circuit 9, after the output of the forward and reverse polarity work protection circuit 9 of the power supply is connected in series with the described constant current discharge load intelligent control circuit 5 and discharge load circuit 6, then connect the DC-DC converter 12, All the other structures are the same as in Embodiment 2.

[0065] Explanation: The power input distributed in the DC-DC converter 12, the constant current discharge load intelligent control circuit 5 and the DC-DC host power supply 1 in the second embodiment all have the function of forward and reverse polarity work protection circuit, and The third embodiment is to supply the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com