Automatic energy-saving online maintenance equipment and system for storage battery of power substation

A technology for maintaining equipment and substations, which is applied in the field of automatic energy-saving online maintenance equipment and systems to achieve the effect of improving system maintenance work safety and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

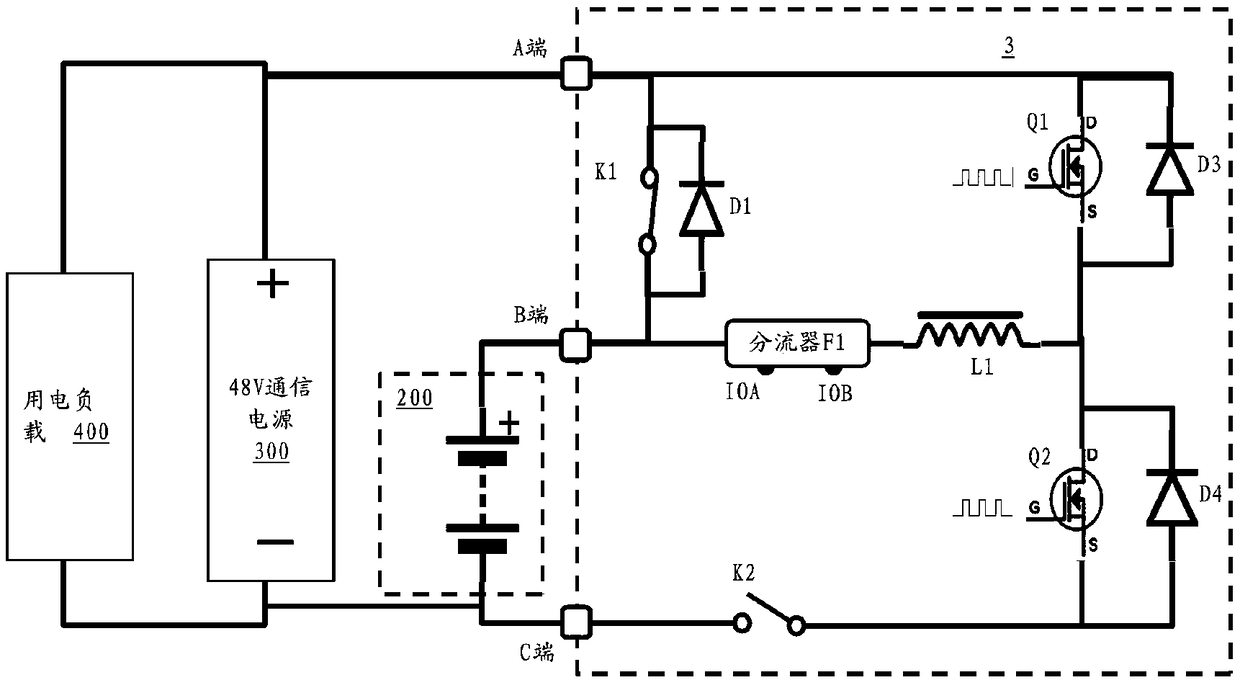

[0040] see figure 1 As shown, the power substation involved in the automatic energy-saving online maintenance equipment 100 of the present invention includes a storage battery pack 200, a communication power supply 300, and an electrical load 400. The load of various communication equipment on the network, figure 1 The communication power supply 300 is 48V as an example, but the present invention is not limited thereto.

[0041] The automatic energy-saving online maintenance device 100 of the present invention includes an MCU circuit unit 1, a drive control circuit 2, and an all-on-line charge and discharge and control circuit unit 3, and the all-on-line charge and discharge and control circuit unit 3 includes control input terminals O and A, The three terminals B and C, and the high-power diode D1, the negative pole of the high-power diode D1 is connected to the A terminal, the positive pole is connected to the B terminal, and the A terminal is connected to the positive pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com