Battery pole piece, preparation method thereof and secondary battery comprising the same

A technology for battery pole pieces and secondary batteries, which is applied in the direction of secondary batteries, electrode manufacturing, battery electrodes, etc. It can solve the problems of excessive dressing, uneven surface of pole pieces, and restrictions, and achieve high surface density and increase capacity and cycle performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

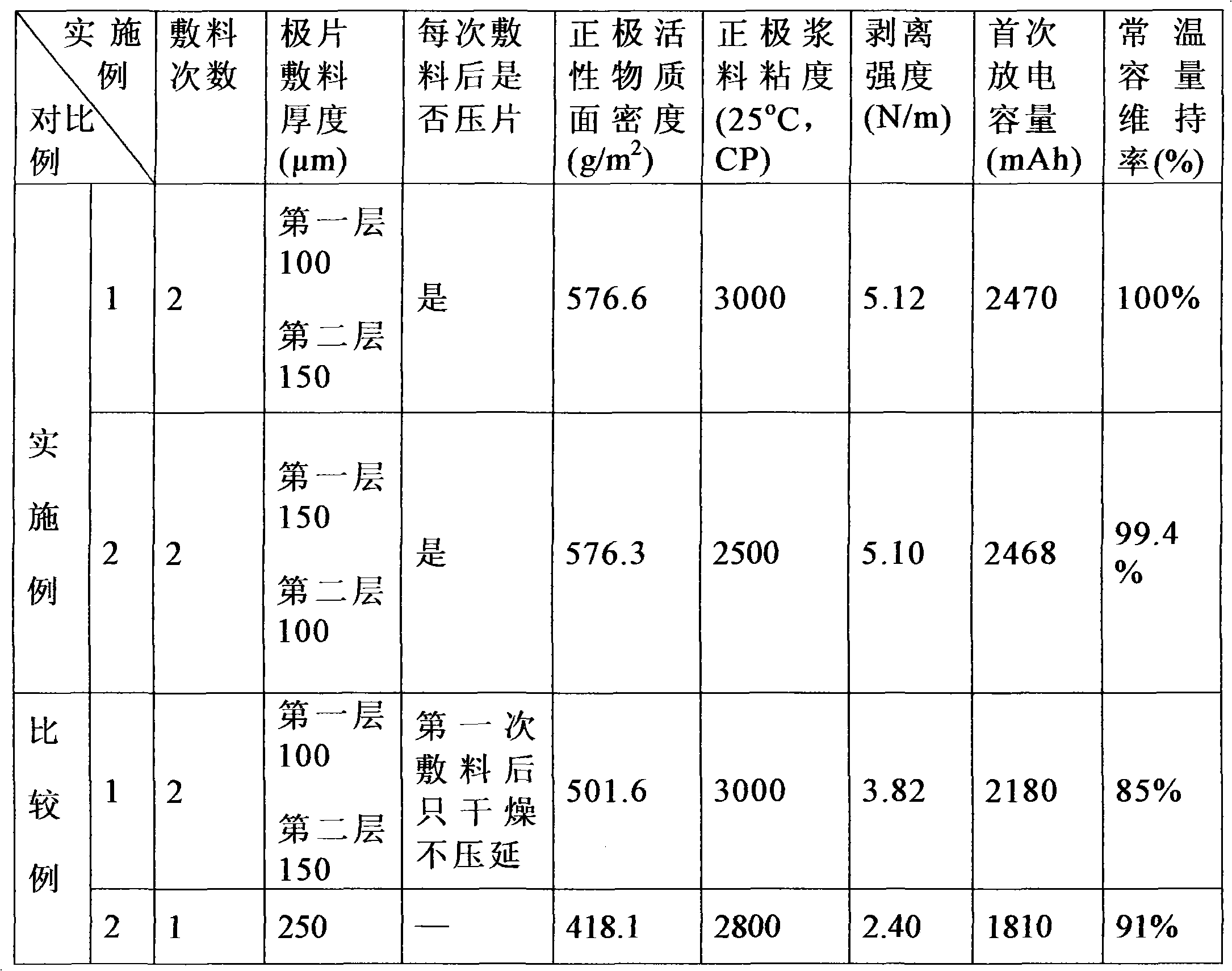

Examples

preparation example Construction

[0011] The specific embodiment of the present invention then provides a method for preparing the above-mentioned battery pole piece, which includes the following steps: firstly apply and / or fill the slurry containing the electrode active material on the current collector substrate, then dry and calender to obtain Pole pieces of electrode material;

[0012] Then repeat the following operation at least once to make a battery pole piece: coating and / or filling the slurry containing the electrode active material on the pole piece coated with the electrode material, then drying and calendering.

[0013] The battery pole piece obtained by the above method is made into a battery pole piece by completing the process of dressing→drying→calendering several times, so the electrode material on the current collector has at least two layers. Specifically, several times of dressing → Drying → calendering operation, there are several layers of electrode materials on the current collector. Mo...

Embodiment 1

[0047] 1. Preparation of lithium-ion secondary battery cathode sheet:

[0048] Preparation of positive electrode slurry: the positive active material lithium iron phosphate (LiFePO 4 ): Adhesive PVDF: Additive Carbon black is added to 700 grams of solvent N, N-dimethylpyrrolidone (NMP) in a mass ratio of 92:4:4, and mixed evenly to make a positive electrode slurry with a viscosity of 3000CP. LiFePO 4 , Adhesive, carbon black, solvent (NMP) consumption are respectively 9200 grams, 400 grams, 400 grams, 700 grams.

[0049] Primary dressing: Coat the positive electrode slurry obtained in the previous step on both surfaces of a 16 μm thick aluminum foil (positive current collector), then dry at 120°C for 0.5 hours, and finally roll it with a tablet machine to obtain a primary dressing the positive plate. The thickness of the positive electrode material on the positive electrode sheet of the first coating obtained after calendering (that is, the thickness of the double-sided coa...

Embodiment 2

[0056] According to the method of Example 1, the difference is that the thicknesses of the first and second dressings are 150 μm and 100 μm respectively, and correspondingly, the thicknesses of the first single-sided dressing and the second single-sided dressing are 75 μm and 50 μm respectively. The content of the positive electrode active material on each positive electrode sheet is 18.5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com