Radio identification label making device

A technology for wireless identification and production of devices, applied to record carriers, instruments, computer parts and other directions used in machines, and can solve problems such as unstable transmission, damage to IC chips, antenna parts, sheet parts, and printing penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

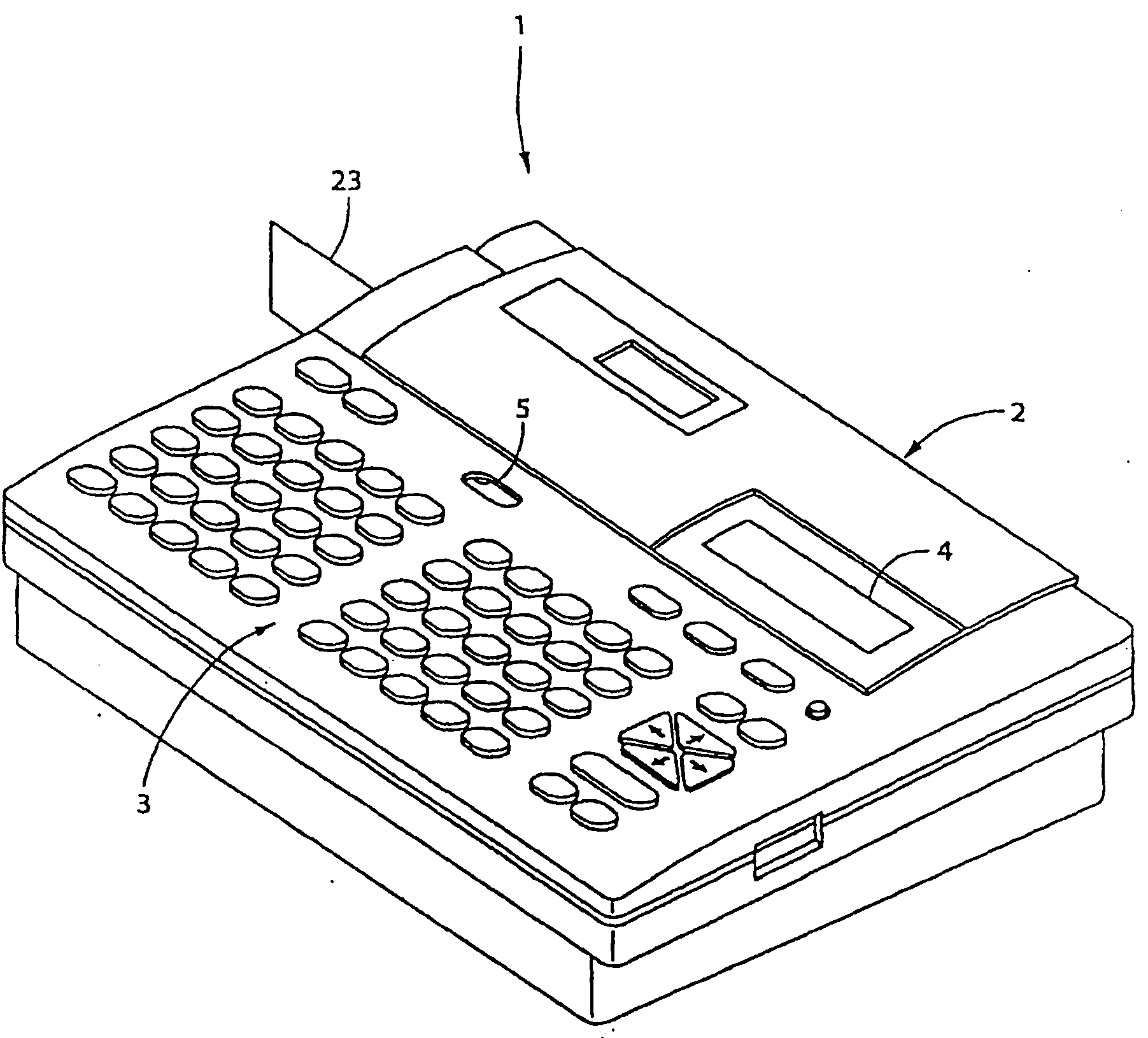

[0073] figure 1 It is a perspective view showing the whole of the wireless identification tag manufacturing apparatus 1 for manufacturing a wireless identification tag 70 called a wireless tag or the like.

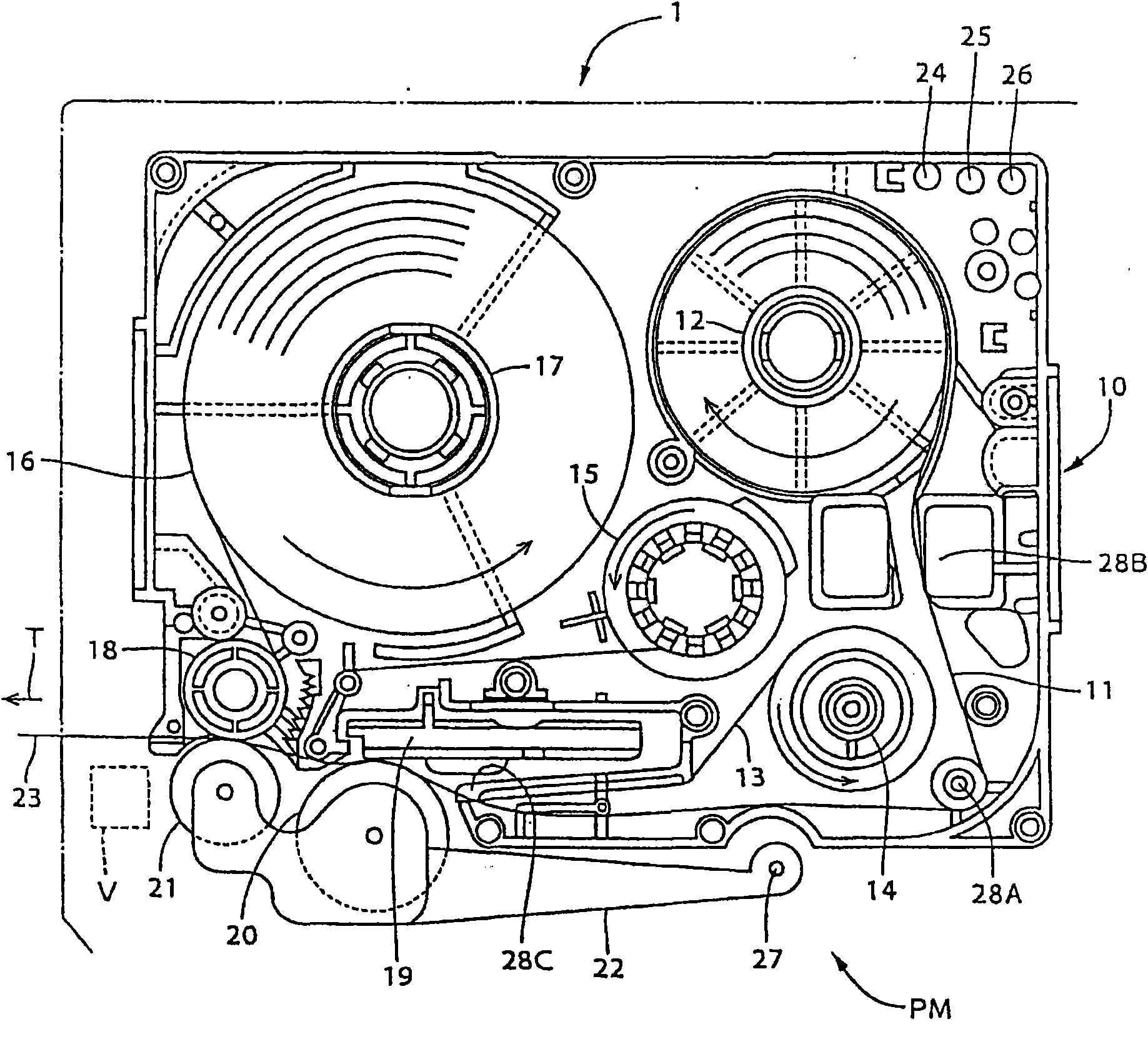

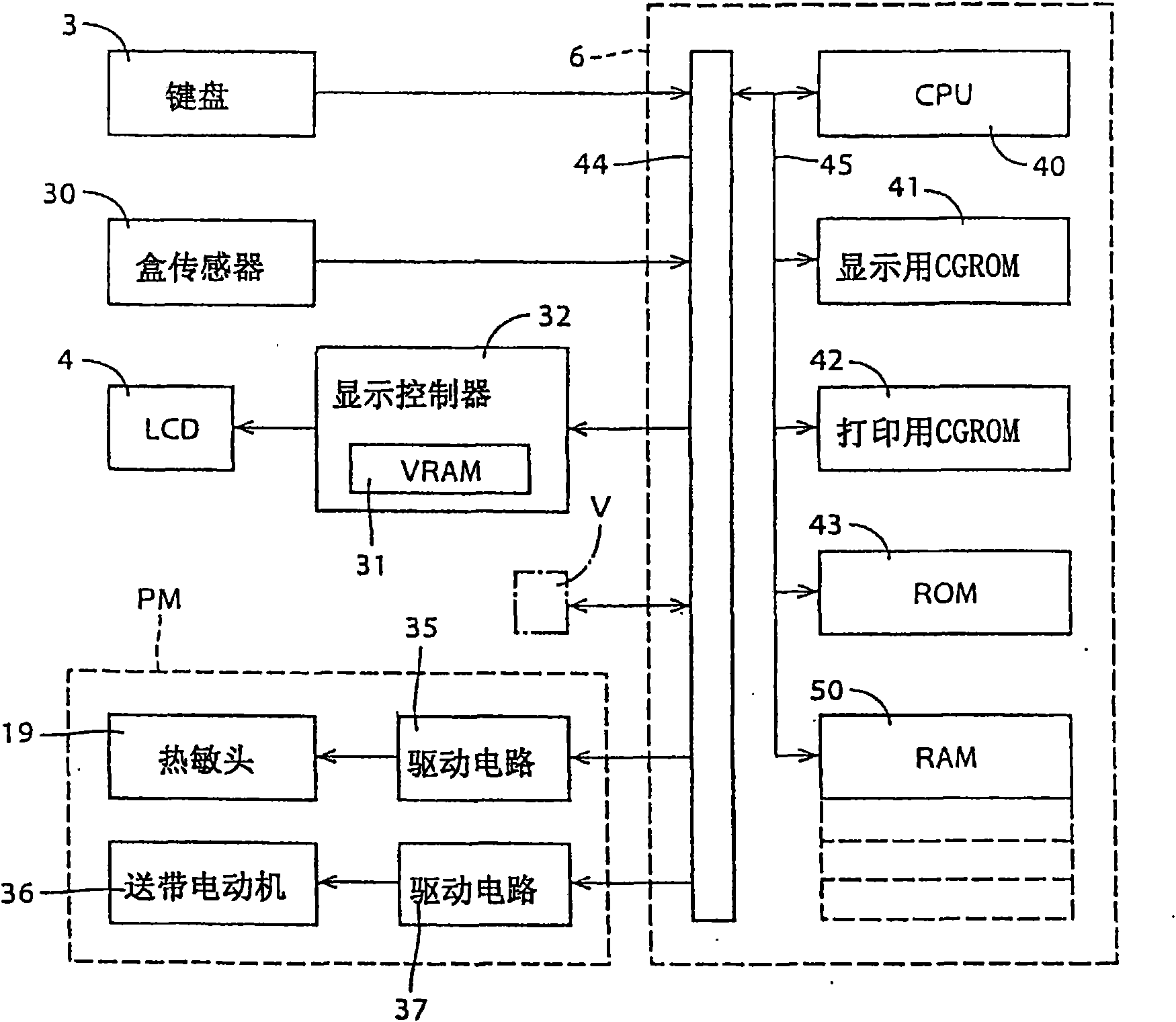

[0074] exist figure 1 Among them, a keyboard 3 is arranged at the front of the wireless identification label making device 1, and a thermal printing mechanism PM corresponding to the image forming unit of the present invention is arranged inside the wireless identification label making device 1 behind the keyboard 3 (refer to figure 2 ). And, on the rear side of the keyboard 3 there is a figure 2 The illustrated box 10 is provided as an openable and closable cover case 2 , and a display 4 such as a liquid crystal display (LCD) for displaying input characters, symbols, and the like is arranged in the cover case 2 . Furthermore, an operation knob 5 for opening and operating the cover 2 is arranged between the cover 2 and the keyboard 3 .

[0075] Keyboard 3 is provided...

no. 2 approach

[0119] Next, other embodiments of the present invention will be described. In addition, in the following description, the same reference numerals are assigned to the same parts as those of the above-mentioned embodiment, and the description thereof will be omitted.

[0120] Figure 7 (A) is a side sectional view of the wireless identification tag 70 using the laminated tape 11 of another form. Should Figure 7 The wireless identification tag 70 shown is the same as that described above (refer to Figure 4 and Figure 5 ) The wireless identification tag 70 differs only in the laminated tape 11 used to make the wireless identification tag 70 .

[0121] Figure 7 The laminated tape 11 of the embodiment of (A) is not a simple transparent film, but contains a coupler prepared in such a way that the heated portion is colored by local heating on the side of the tape-shaped sheet member 16 to be bonded. , and has a heat-sensitive layer 11A, so that the partial coloration is a pr...

no. 3 approach

[0154] Figure 11 It shows a case in which a square or rectangular sheet member 16 or a wireless identification tag 70 is housed in a box P as a package shown by a dotted line for single product sales of the strip-shaped sheet member 16 . At this time, each tape is peeled off one by one and conveyed, and the wireless identification tag 70 is manufactured sequentially. Even in this case, the image printed on the wireless identification tag 70 can be kept in good condition without damaging the IC chip 64 and the like inside the wireless identification tag 70 .

[0155] In addition, in the thickness direction, between the adjacent sheet members 16 or RFID tags 70, the IC chips 64 are staggered and arranged in the plane direction, so that the box P can be reduced in size, or it can be accommodated in boxes P of the same size. There are many sheet members 16 or wireless identification tags 70 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com