Module for testing dielectric strength of automotive relay

An automotive relay and electric strength technology, applied in circuit breaker testing and other directions, can solve the problems of easy omission and error, low flexibility, low production efficiency, etc., and achieve the effect of flexible and efficient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

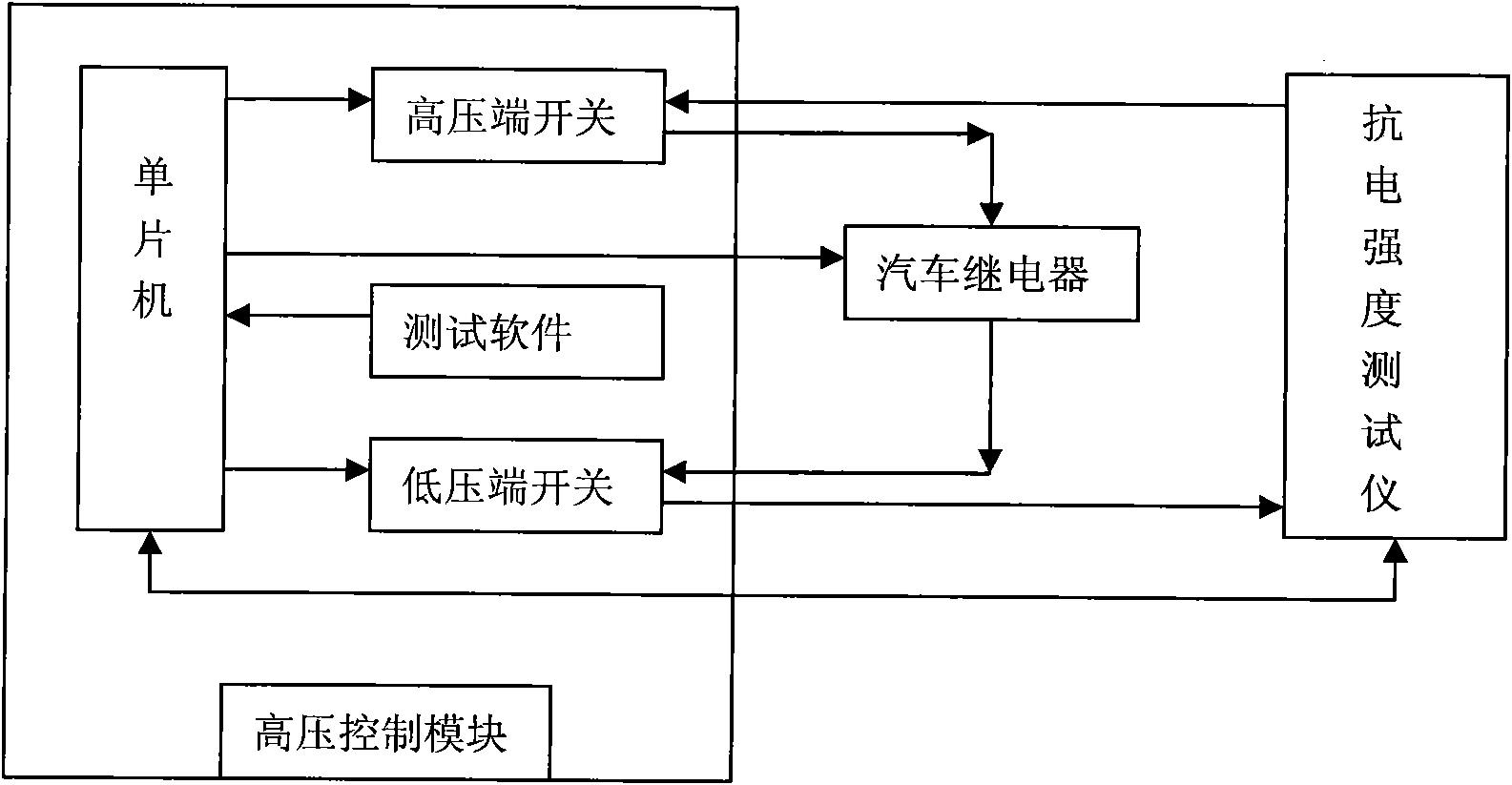

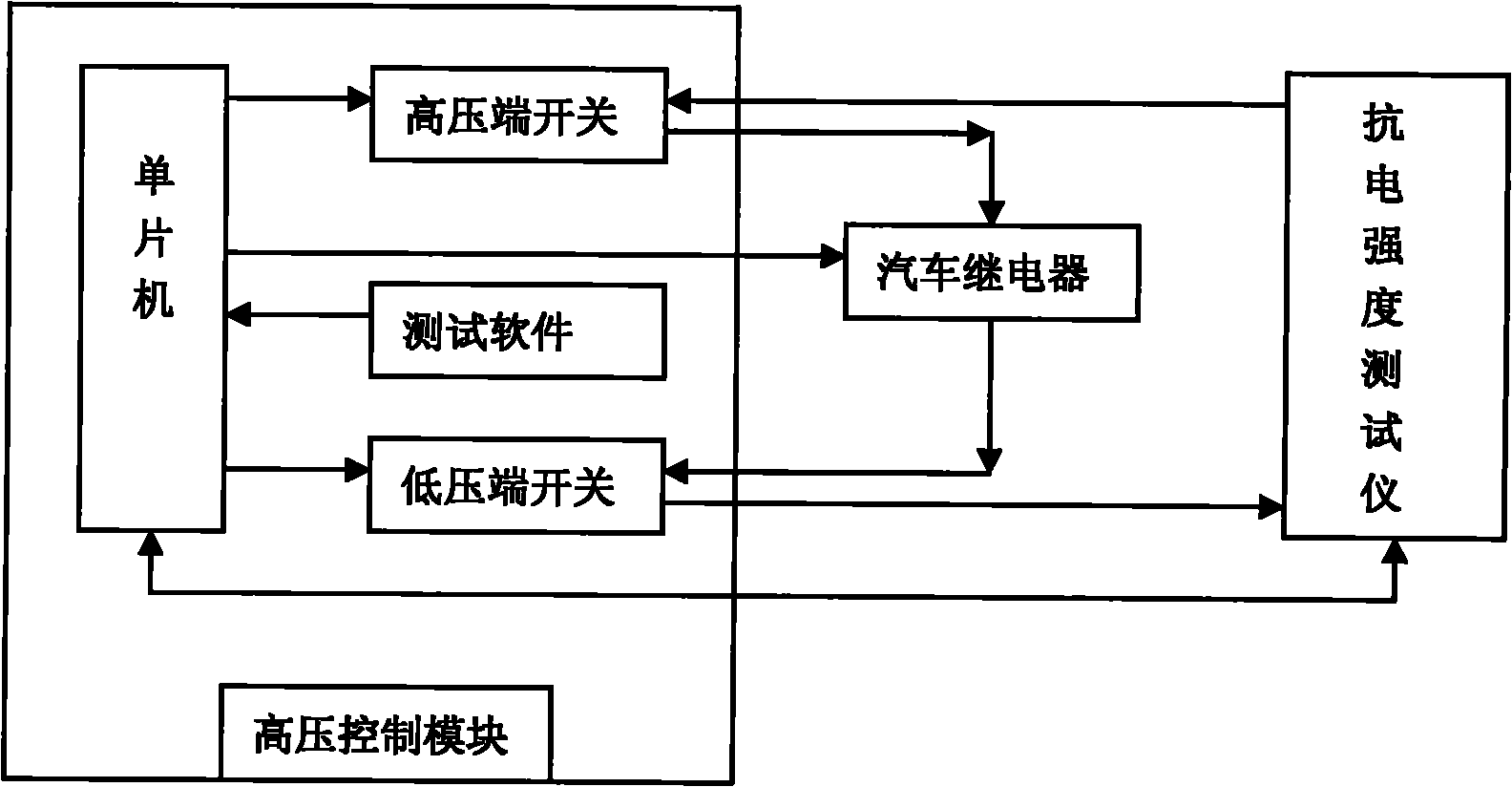

[0012] As shown in the figure, the working process of the module of the present invention is as follows, the hardware part: the output high voltage of the electric strength tester returns to the output low voltage end of the electric strength tester through the high-voltage end switch, the automobile relay, and the low-voltage end switch; Control of switches, automotive relays, low-voltage side switches and dielectric strength tester; software part: MCU first starts the high-voltage output of the dielectric strength tester, controls the high-voltage side switch and low-voltage side switch to complete the dielectric strength of different connection parts of the automotive relay Testing requirements. After the test is completed, cut off the high voltage output of the electric strength tester, and cut off the high voltage end switch and the low voltage end switch. Finally, what is the test result of the dielectric strength tester? For the different connection modes of different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com