A universal electric strength detection device

A technology of electric strength and detection device, applied in the direction of testing dielectric strength, etc., can solve the problems of easy occurrence of electric shock, affecting production progress, time-consuming and laborious, etc., and achieves a simple and smooth detection process, improved work efficiency, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

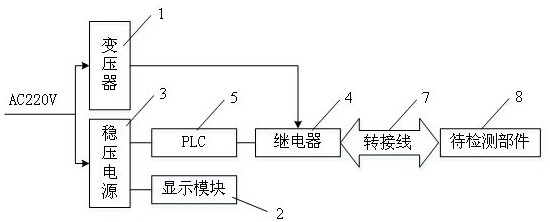

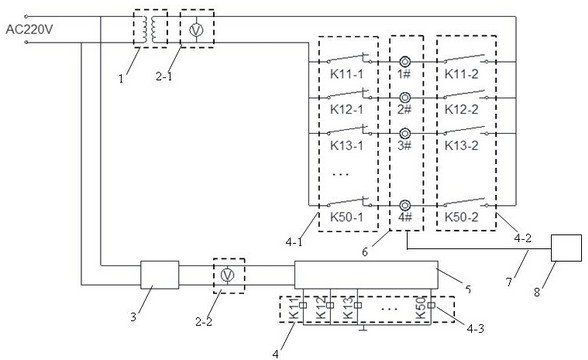

[0012] Now, the technical solutions in the embodiments of the present invention will be clearly and completely described in conjunction with the accompanying drawings. The accompanying drawings are simplified schematic diagrams and only schematically illustrate the basic structure of the present invention.

[0013] like figure 1 As shown, the present invention includes a relay group 4, an input end of the relay group 4 is connected with a transformer 1 that can convert the mains AC220V and output a standard detection voltage of AC500V; the other input end of the relay group 4 It is connected with a programmable controller PLC5 which can control the electrical signal of the relay group 4; the output terminal of the relay group 4 is connected to the component to be detected 8 through the transfer line 7; The programmable controller PLC5 provides a regulated power supply 3 of working voltage; it also includes a display module 2 for displaying the voltage at the output terminal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com