Internal combustion engine

An internal combustion engine, gas technology, applied in the direction of internal combustion piston engine, combustion engine, fuel system, etc., to achieve the effect of improving service life, reducing temperature load, and improving maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

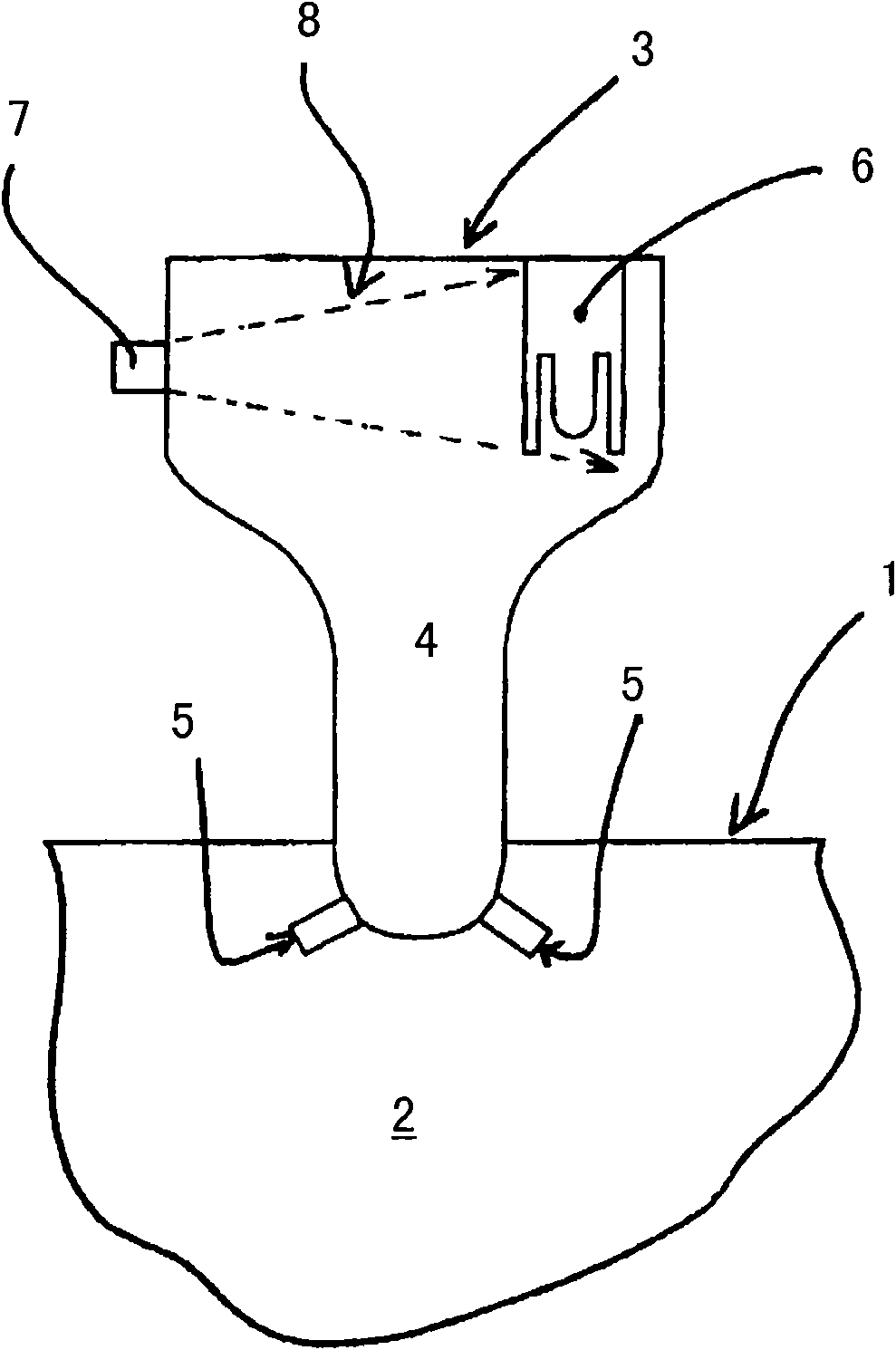

[0018] figure 1 A partial schematic diagram of a preferred exemplary embodiment of the internal combustion engine according to the invention is shown. The internal combustion engine is preferably designed as an Otto gas engine, this part being the region of the cylinder head 1 of the internal combustion engine, which delimits the main combustion chamber 2 of the internal combustion engine. according to figure 1 , a component 3 is arranged on the cylinder head 1 of the internal combustion engine. Said component is preferably screwed into the cylinder head 1 , wherein the component 3 delimits a pre-combustion chamber 4 . The pre-combustion chamber 4 is separated from the main combustion chamber 2 and connected to the main combustion chamber 2 through at least one opening 5 .

[0019] The ignition device 6 protrudes into the pre-combustion chamber 4 . The ignition device preferably has at least one ignition electrode and is designed as a spark plug. Gas can be injected into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com