Blowout preventer turning system

A blowout preventer and flip frame technology, which is applied in the field of flip systems, can solve problems such as difficulty in ensuring safety and reliability, failure to ensure construction safety, time-consuming and laborious flipping, etc., to save flipping time, occupy a small area, and save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

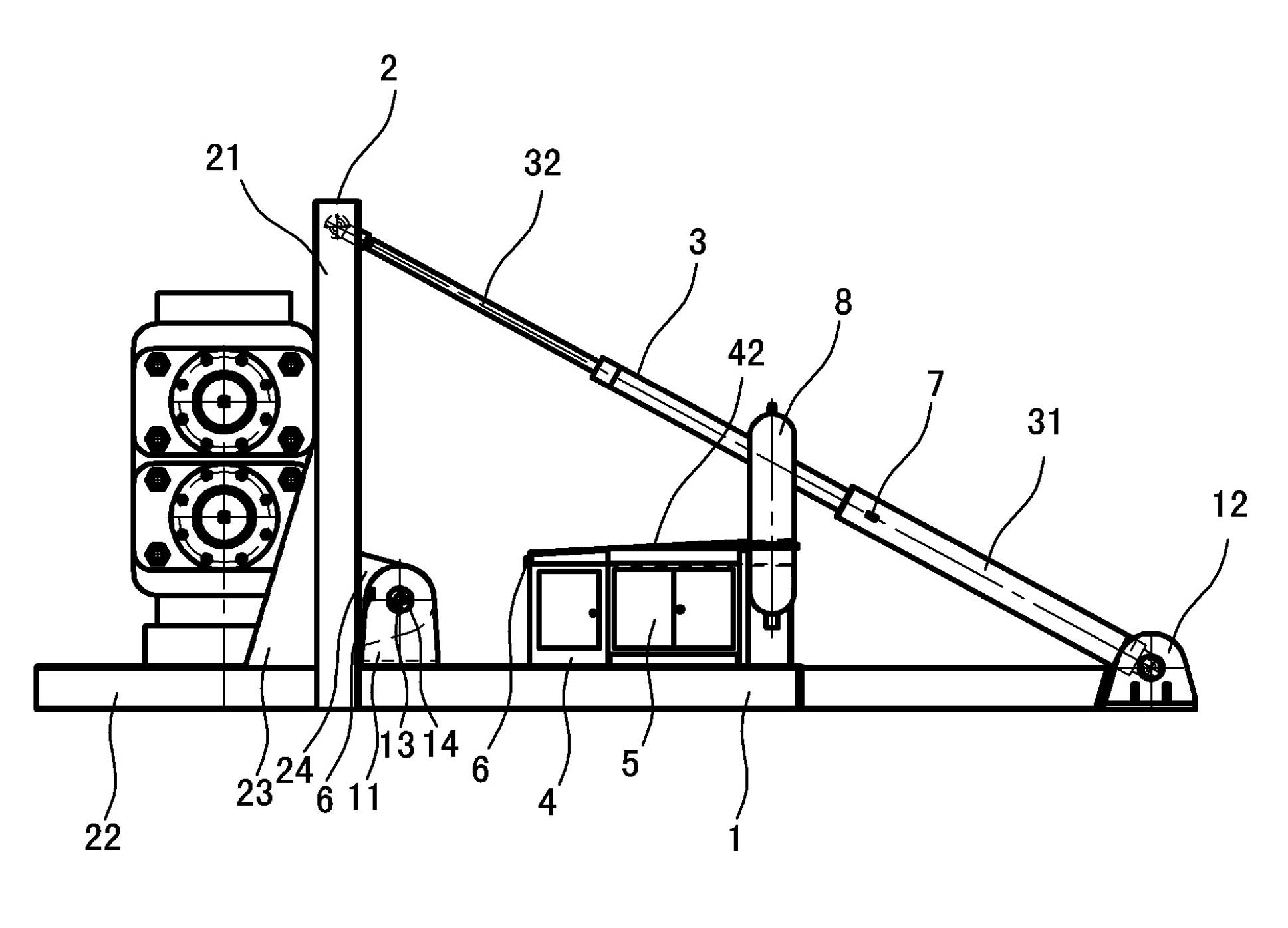

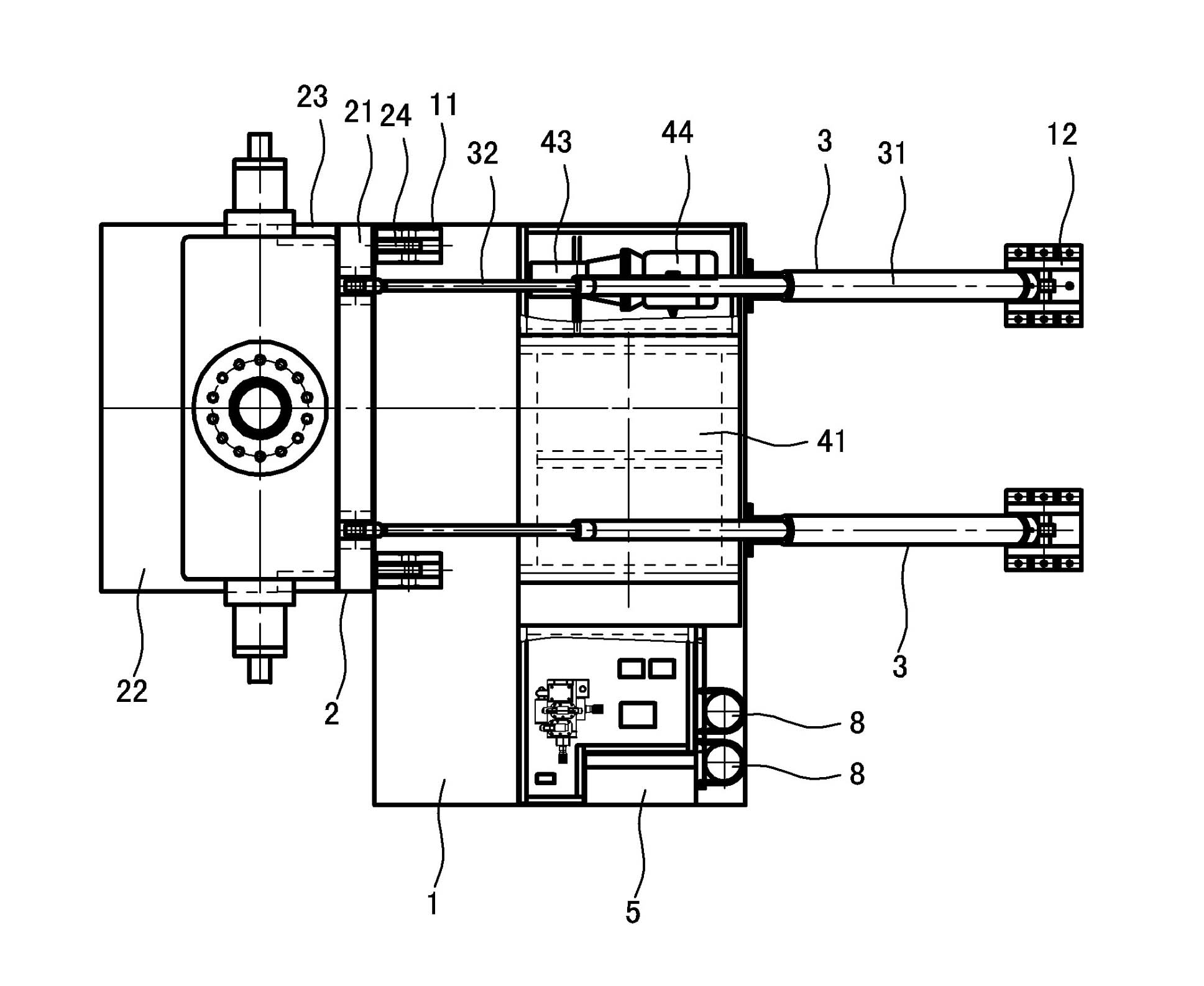

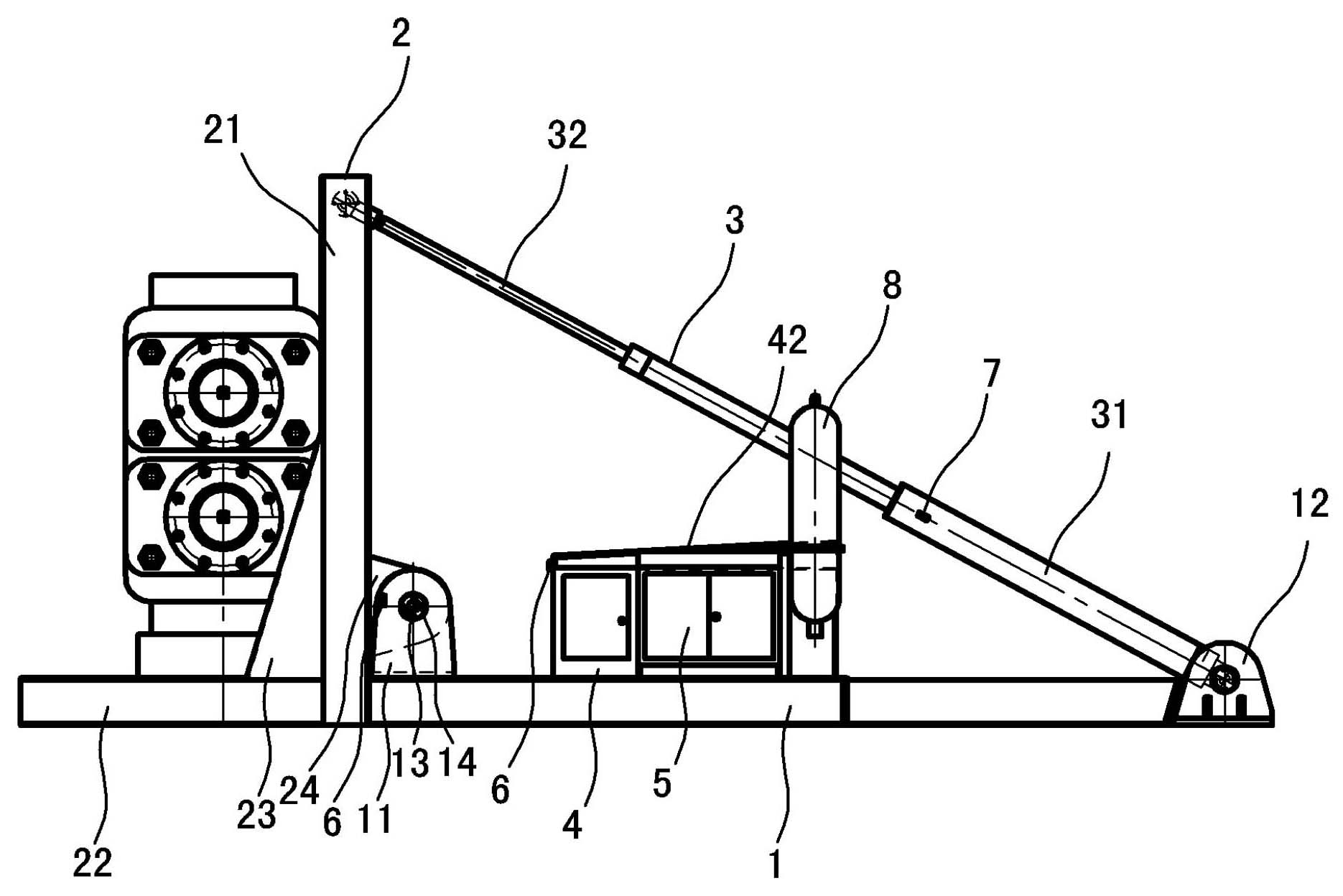

[0011] Such as figure 1 , figure 2 As shown, it includes a base 1, a load-bearing overturn frame 2, a hydraulic overturn cylinder 3, a hydraulic station assembly 4 and an electric control device 5, the load-bearing overturn frame 2 is horizontally hinged on the base 1, and the cylinder body 31 of the hydraulic overturn cylinder 3 is hinged on the On the base 1, the end of its piston rod 32 is hinged with the load-bearing overturn frame 2. The push-pull load-bearing overturn frame 2 turns over, and the hydraulic overturn cylinder 3 is connected with the hydraulic station assembly 4 through the high-pressure oil pipeline. The hydraulic station assembly 4 and the electric control Device 5 is connected.

[0012] The load-bearing overturn frame 2 is a cross-sectional L-shaped body formed by connecting the first load-bearing plate 21 and the second load-bearing plate 22 perpendicular to each other on one side. Ribs 23 are connected between the first bearing plate 21 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com