Mechanical processing device and method of ceramic-based complex curved surface parts with wave transmissivity

A complex curved surface and mechanical processing technology, which is applied in the field of mechanical processing, can solve the problems of scrapped parts, broken parts, etc., and achieve the effect of simple processing, good product quality and improved processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

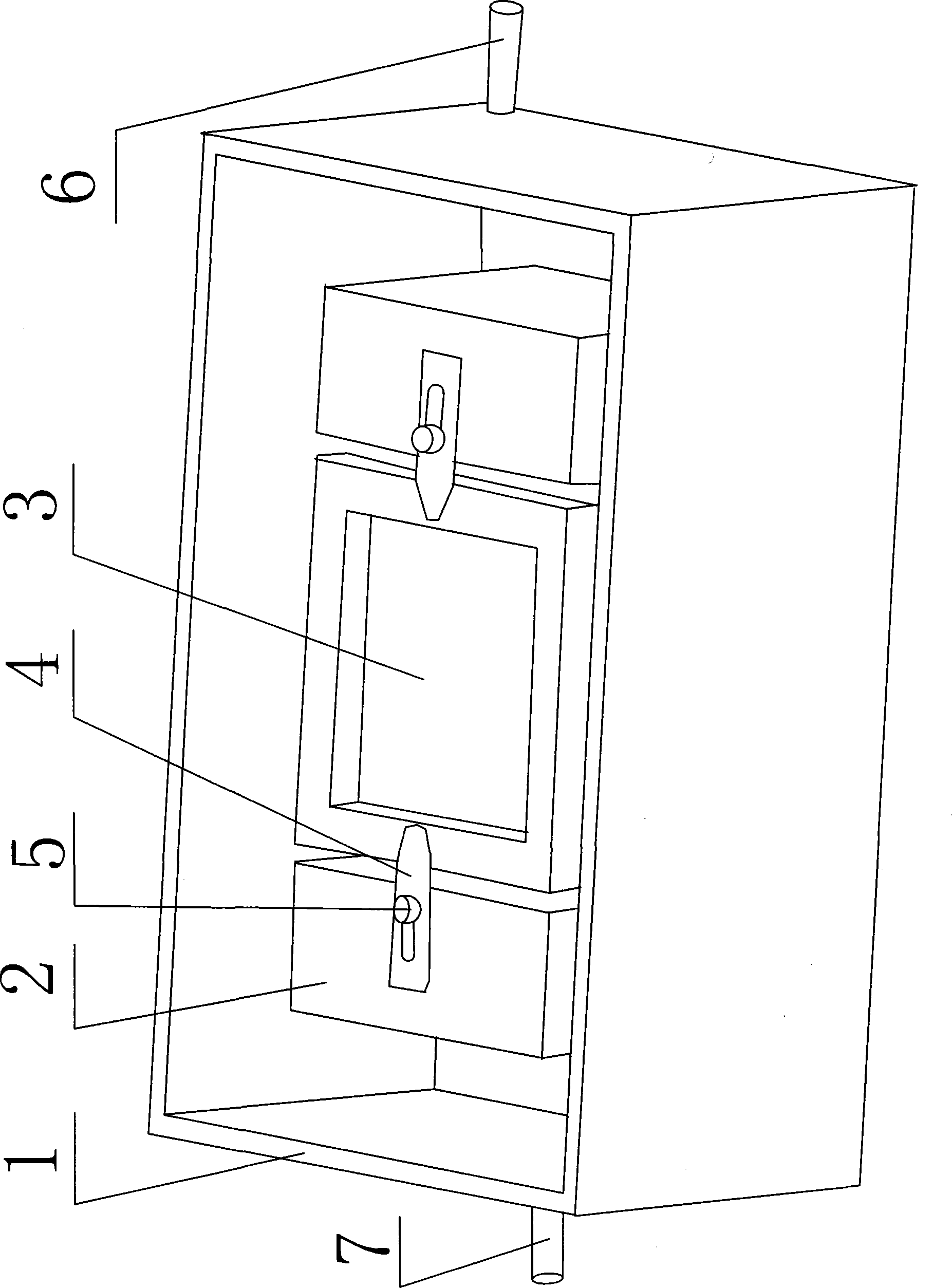

[0027] A mechanical processing device for a ceramic-based complex curved surface part with wave-transmitting performance, its composition includes: a water storage tank 1 used for a ceramic-based complex curved surface part with wave-transparent performance, the water storage tank 1 is equipped with a pad 2, and the pad The workpiece 3 is installed in the middle of the block 2, and the tongs 4 with oblong holes are installed on the described cushion block 2, and the described tongs 4 are fixed on the cushion block 2 with bolts 5 when pressing the workpiece, and the described water storage tank 1 A water outlet 6 is installed below the outer side, and a water inlet 7 is installed above the outer side of the water storage tank 1 .

Embodiment 2

[0029] The mechanical processing device of the wave-transmissive radome described in Embodiment 1, the ceramic-based complex curved surface part with wave-transmissive performance, for example, the size of the wave-transparent radome includes external dimensions and inner cavity dimensions, and the external dimensions include The size of the lower frame and the size of the upper boss, the size of the lower frame includes the length, the size of the radome includes the outer dimension and the inner cavity size, the outer size includes the length of the lower frame 130± 0 0.02 mm, width 120± 0 0.02 mm, the height of the lower frame is 16±0.1mm, and the length of the upper boss is 120± 0 0.02 mm, the width of the upper boss is 110± 0 0.02 mm; the inner cavity size includes, the inner cavity length is 100±0.1mm, and the width is 90±0.1mm. 0 0.15 mm.

[0030] The tolerance level of the size of the wave transparent radome is IT5; the size range of the workpiece processed by ...

Embodiment 3

[0033] Embodiment 1 The mechanical processing method of a ceramic-based complex curved surface part with wave-transmitting performance, the processing method: first formulate the rough machining thickness, then rough the shape and inner cavity, and then finish the inner cavity surface, and then carry out Finishing the outer surface and finally drilling, the coolant used in the above-mentioned processing process should use pure water, the said cooling liquid is not allowed to contain ions, and no metal is allowed in the above-mentioned processing process The powder is in contact with the workpiece, and the water storage tank is filled with pure water during the above-mentioned processing, so that the workpiece is immersed in the water, that is, submerged processing.

[0034] The processing method of the ceramic-based complex curved surface part with wave-transmitting performance:

[0035] (1). Rough machining thickness: Since the raw material of the radome is sintered, the mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com