Process for producing shielding case

A production process and shielding technology, applied in the field of mold production technology, can solve the problems of low production efficiency and poor shielding effect, and achieve the effects of high production efficiency, good flatness and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A production process of a shielding cover, the production process comprises the following steps in sequence:

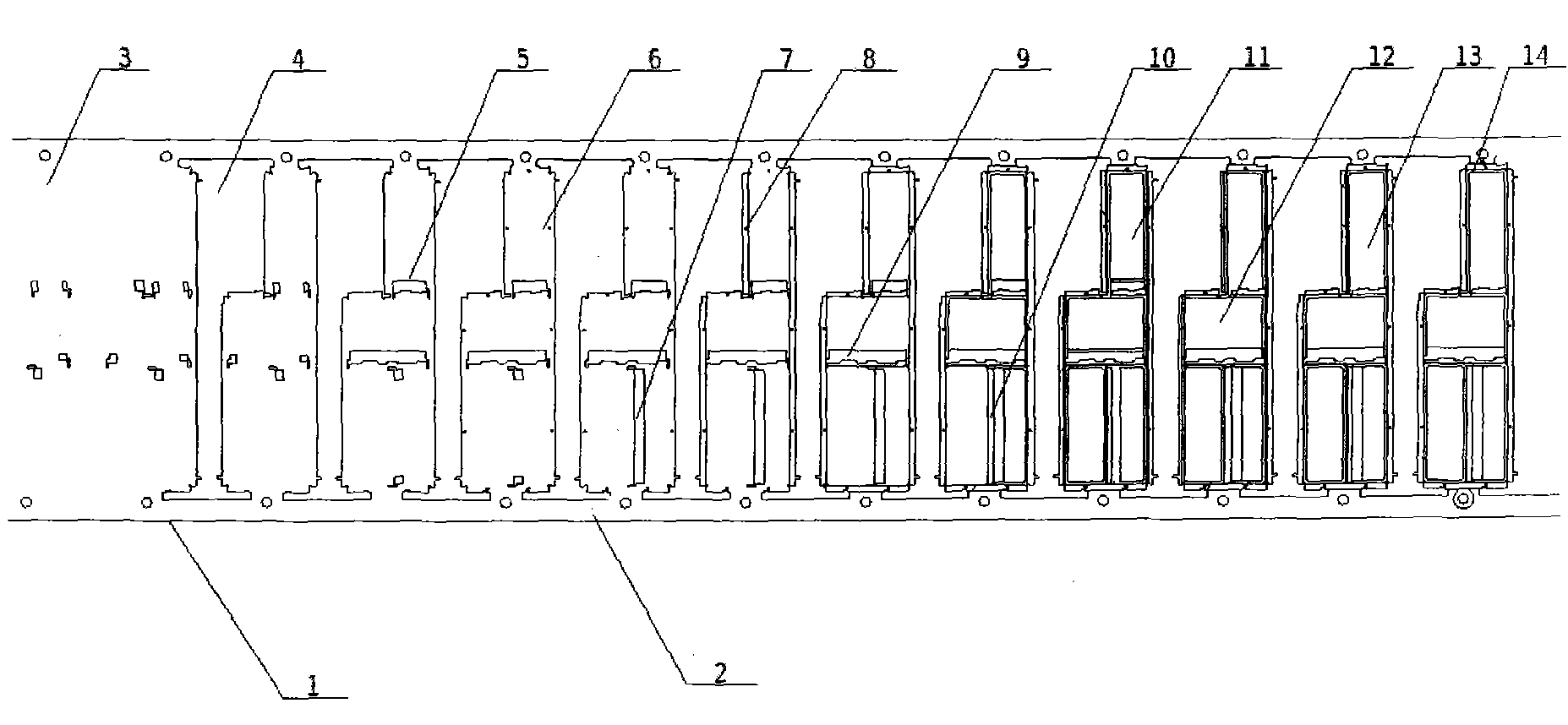

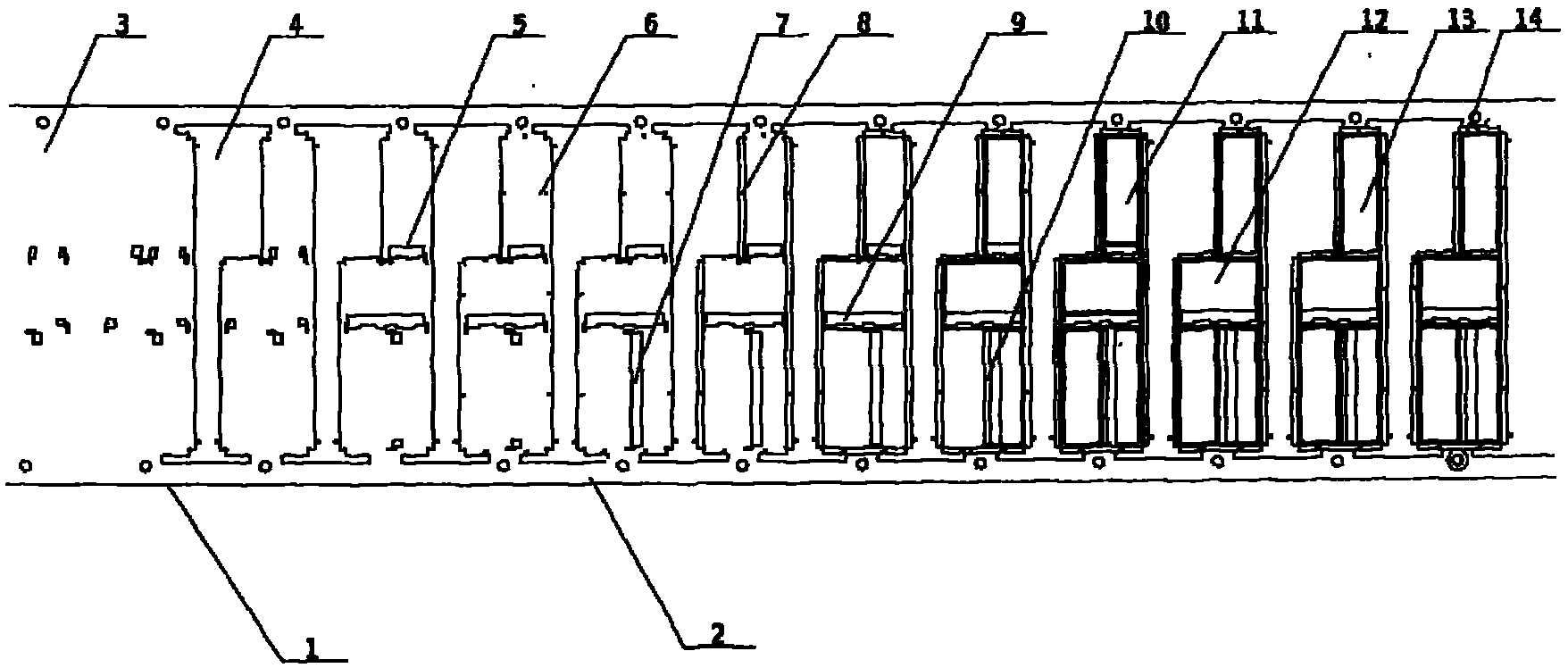

[0031] Step 1: firstly connect the punching machine to the lower die base, and then fix the lower template on the other side of the lower die base, and then set the pre-punching module, the flash module, the middle punching module, the punching module on the lower template in sequence. Bump module, bottom punching module, three-side folding module, one-side folding module, two-side folding module, upper punching module, empty module, leveling block and two-side folding module;

[0032] Step 2: Put the raw material on the lower template first, then start the machine, and then pre-punching the raw material through the pre-punching module, and then process the periphery of the material by the flashing module to form a shielding cover blank;

[0033] The third step: first punch the middle part of the shield blank by the middle punching module to form a cavity in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com