A spring type tire deceleration brake device

A brake device, spring-type technology, applied in vehicle parts, transportation and packaging, brakes, etc., can solve the problems of easily damaged brakes, waste, irregular replacement of brakes, etc., to achieve precise structure, reasonable structure and convenient production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment, further illustrate the present invention.

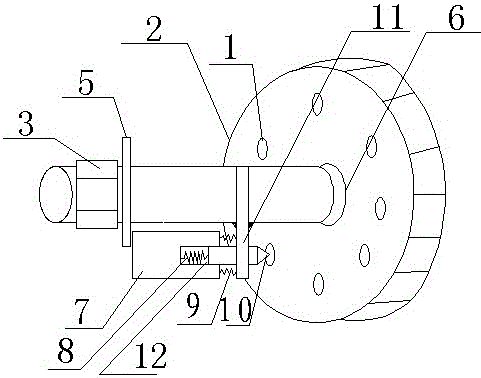

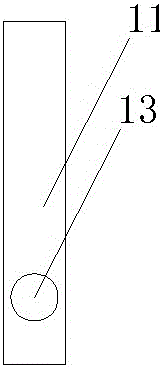

[0019] see figure 1 , the present invention comprises a tire 2 and a wheel shaft 3, the tire 2 is provided with a groove 1, the wheel shaft is provided with a nut 3 capable of moving left and right, one end of the nut 3 is provided with a baffle 5, the wheel shaft One side is provided with a fixed shaft 11, the lower side of the fixed shaft 11 is passed through by the speed reduction pin 10, the lower end of the axle is provided with a sleeve 7, and one end of the sleeve 7 is provided with a notch 12, the notch An inner spring 8 is arranged in the mouth 12 , one end of the inner spring 8 is connected in the notch 12 , and the other end is connected with the speed reduction pin 10 .

[0020] The sleeve 7 is connected to the fixed shaft 11 through an outer spring.

[0021] The number of the grooves 1 is 8.

[0022] The nut 3 is sleeved on the axle through a threaded ring.

[0023] A circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com