Method for producing hollow suppository by utilizing rotary mold

A rotating mold and hollow technology, which is applied in the direction of making medicines into special physical or ingestible devices, can solve problems such as material waste, achieve the effects of reducing costs, saving materials, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

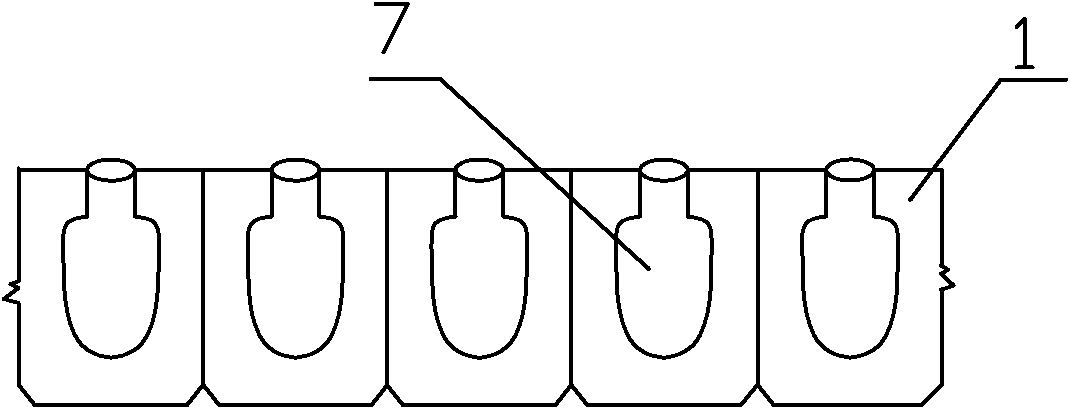

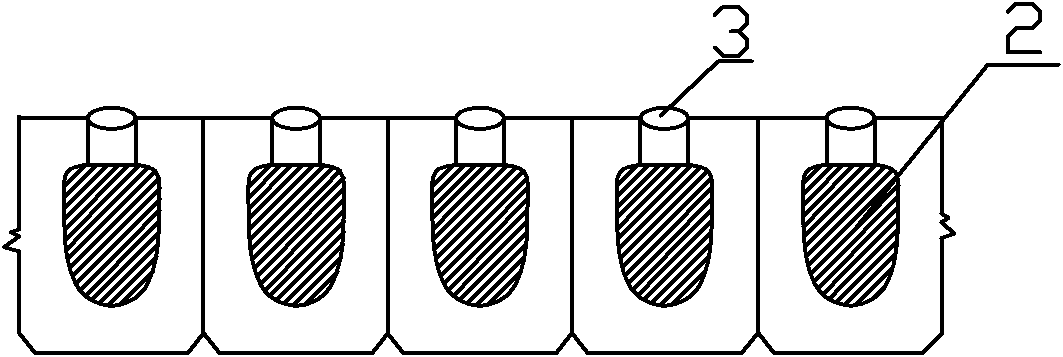

[0030] (1), perfusion: Utilize existing suppository filling machine, the fat-soluble matrix or water-soluble matrix that melts is poured in each cavity 7 of suppository shell 1, see figure 1 , figure 2 ;

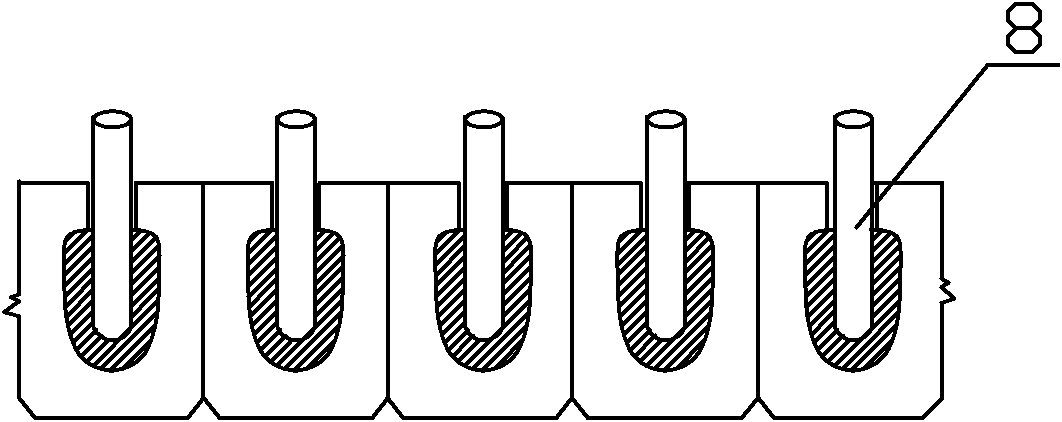

[0031] (2), rotary mold forming hole: insert rotary mold 8 in each capsule cavity 7 of suppository shell before matrix solidifies completely, rotary mold 8 is driven by power unit to rotate in matrix, until the matrix in suppository shell capsule cavity is completely After solidification, the rotary mold is lifted to form a hollow cavity 4 in the matrix of the suppository shell cavity.

[0032] Rotary mold 8 rotating speed control is when rotating mold is extracted from the suppository shell that contains matrix, does not adhere on the rotary mold, or very little adhesion matrix is a standard, and now the rotating speed is 100~200 revolutions per minute.

[0033] The rotary mold 8 is a cylinder rotating along the axis, and the end of the cylinder is in the shape of a sp...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, the difference is that the rotary mold 8 is a solid cylinder rotating along the axis, there is no cold air blind hole inside, and the end of the cylinder is spherical. In the hole forming process of the rotary mold, after the matrix is completely solidified, insert the rotary mold driven by the power device at a speed of more than 7,000 revolutions per minute into the cavity of the suppository shell. During the hole forming process, the rotary mold rotates at high speed while extending into the solidified matrix, and after the matrix in the cavity of the suppository shell forms a hollow cavity, lift the rotary mold. No waste matrix is generated during this process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com