Method for quickly forecasting cooling time in injection molding of plastics

A cooling time, injection molding technology, applied in instruments, biological neural network models, calculations, etc., can solve problems such as being unable to adapt to the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

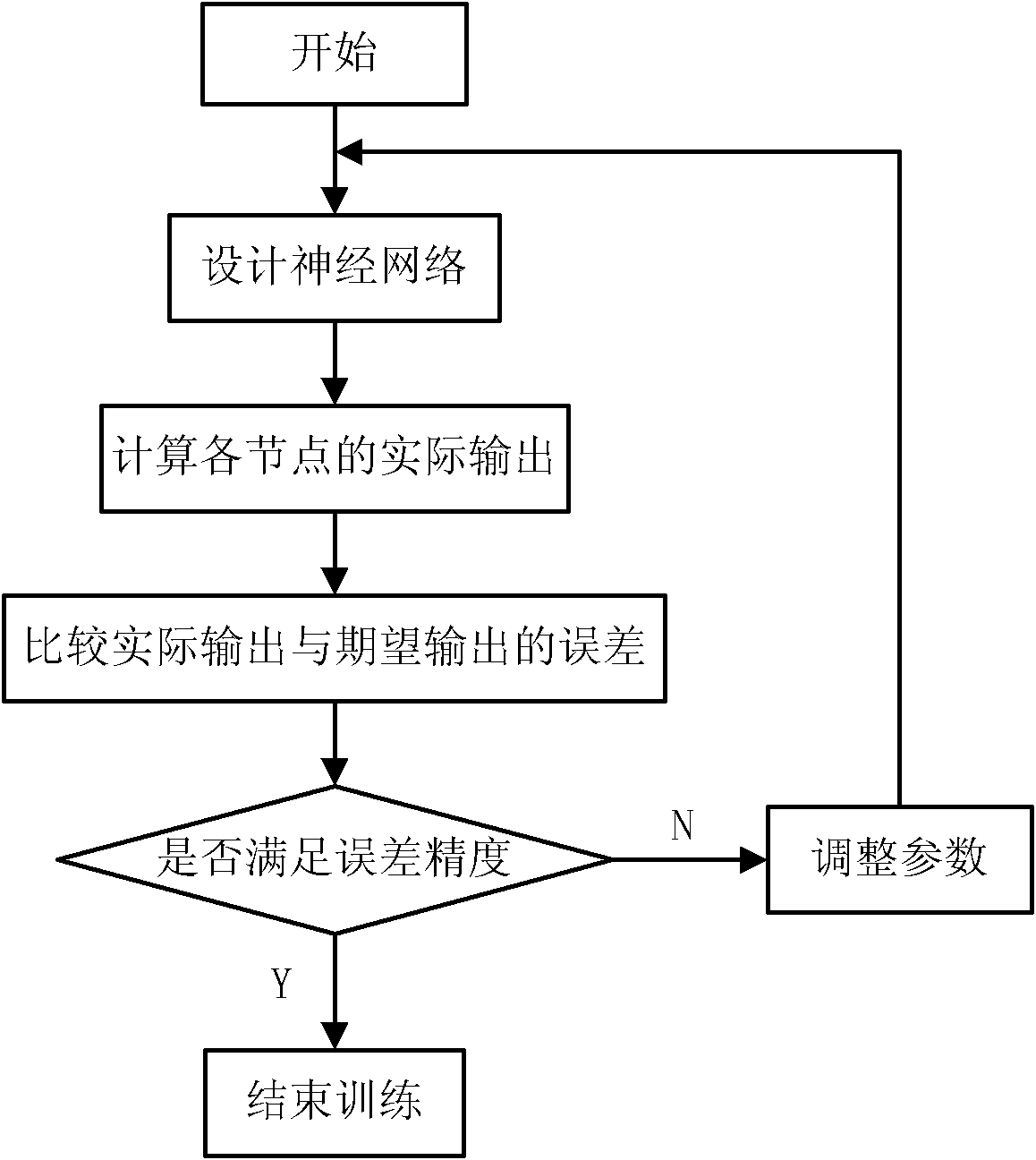

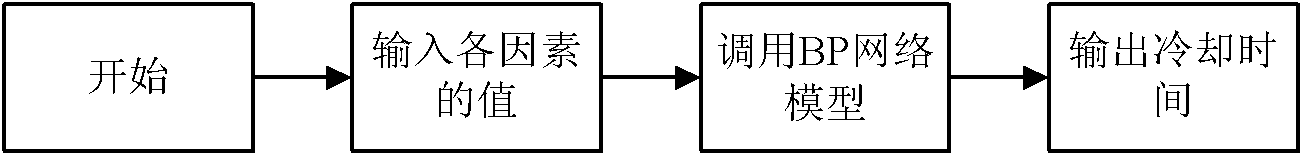

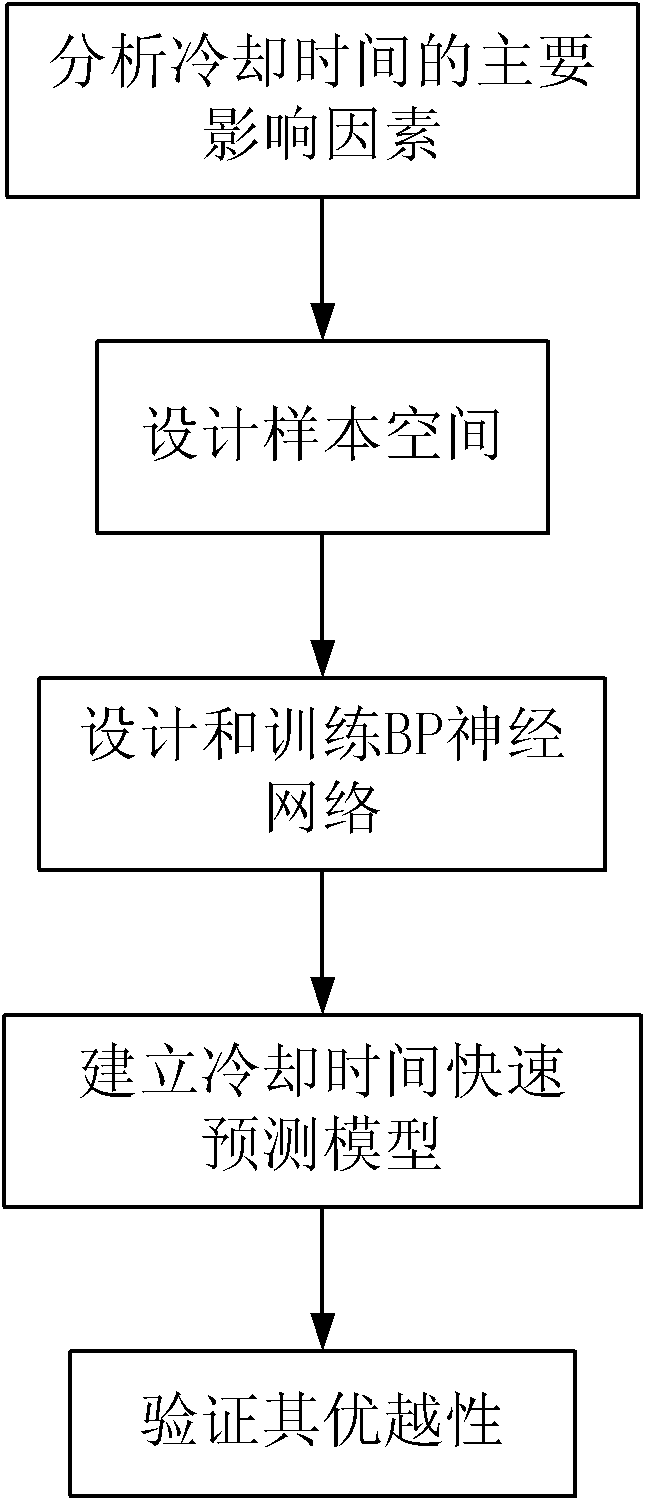

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0028] This paper is based on a flat part to study the rapid prediction method of cooling time in plastic injection molding.

[0029] (1) Determine the main influencing factor of the cooling time, that is, the temperature conductivity coefficient of the mold material α 1 、The thermal conductivity coefficient of plastic materials α 2 , Temperature ratio (Ti-Tc) / (Te-Tc), (where Ti is the injection temperature, Tc is the temperature of the cooling water, Te is the mold opening temperature), the thickness h of the product and the area S of the cooling system, and give each Three different levels of impact factors are set. The length of the selected product is 120mm, the width is 30mm, and the thickness is respectively taken as 3 levels of 2mm, 5mm, and 8mm. Other influencing factors and their levels are shown in Table 1. The size of the mold is 180mm×50mm×50mm.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com