Lubricating oil cooling device of single-stage high-speed centrifugal fan

A high-speed centrifugal and cooling device technology, applied in the components of the pumping device for elastic fluid, mechanical equipment, non-variable-capacity pumps, etc., can solve the problems of secondary pollution, poor climate adaptability of air cooling, etc. The effect of high cooling efficiency and low sensitivity to ambient temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

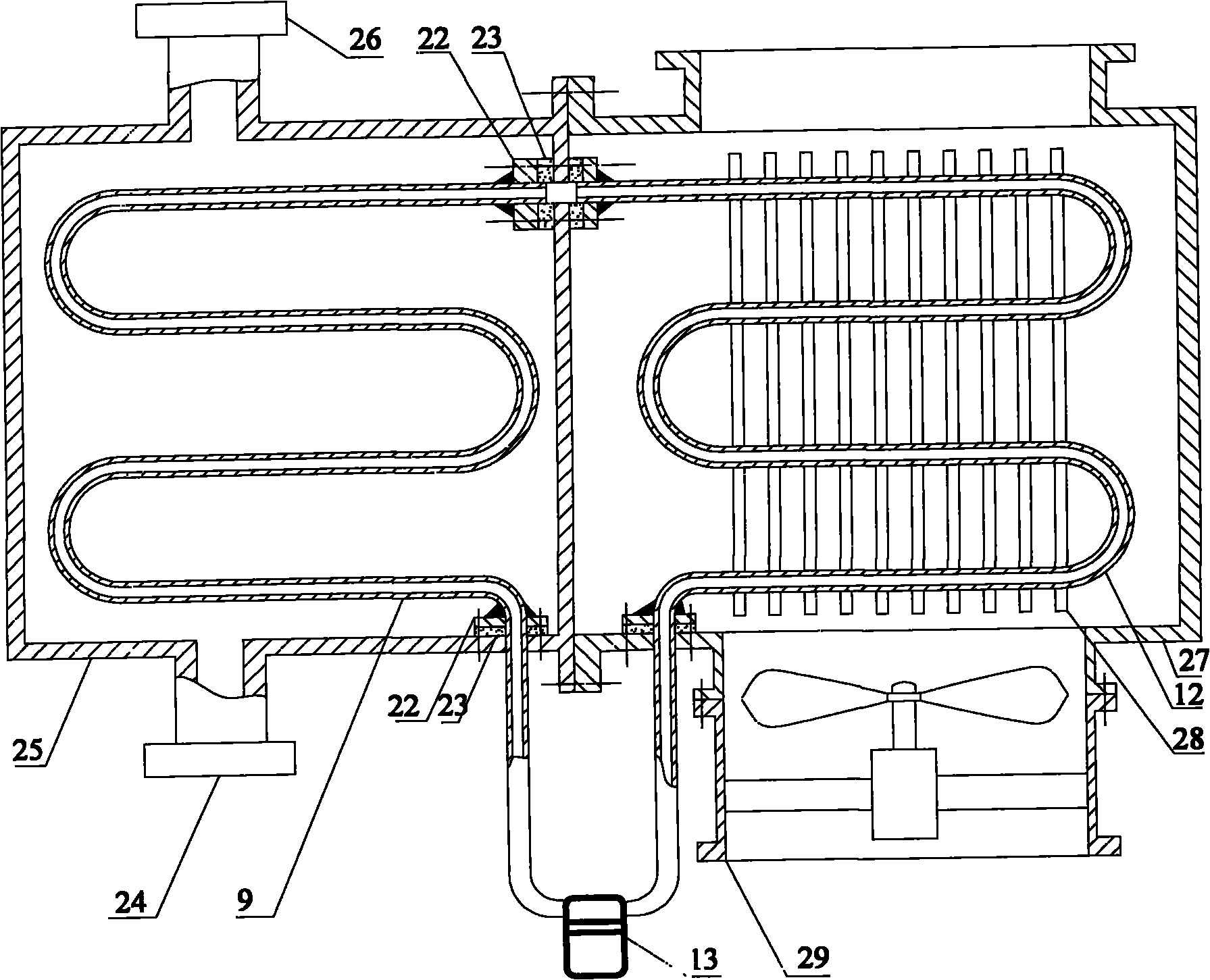

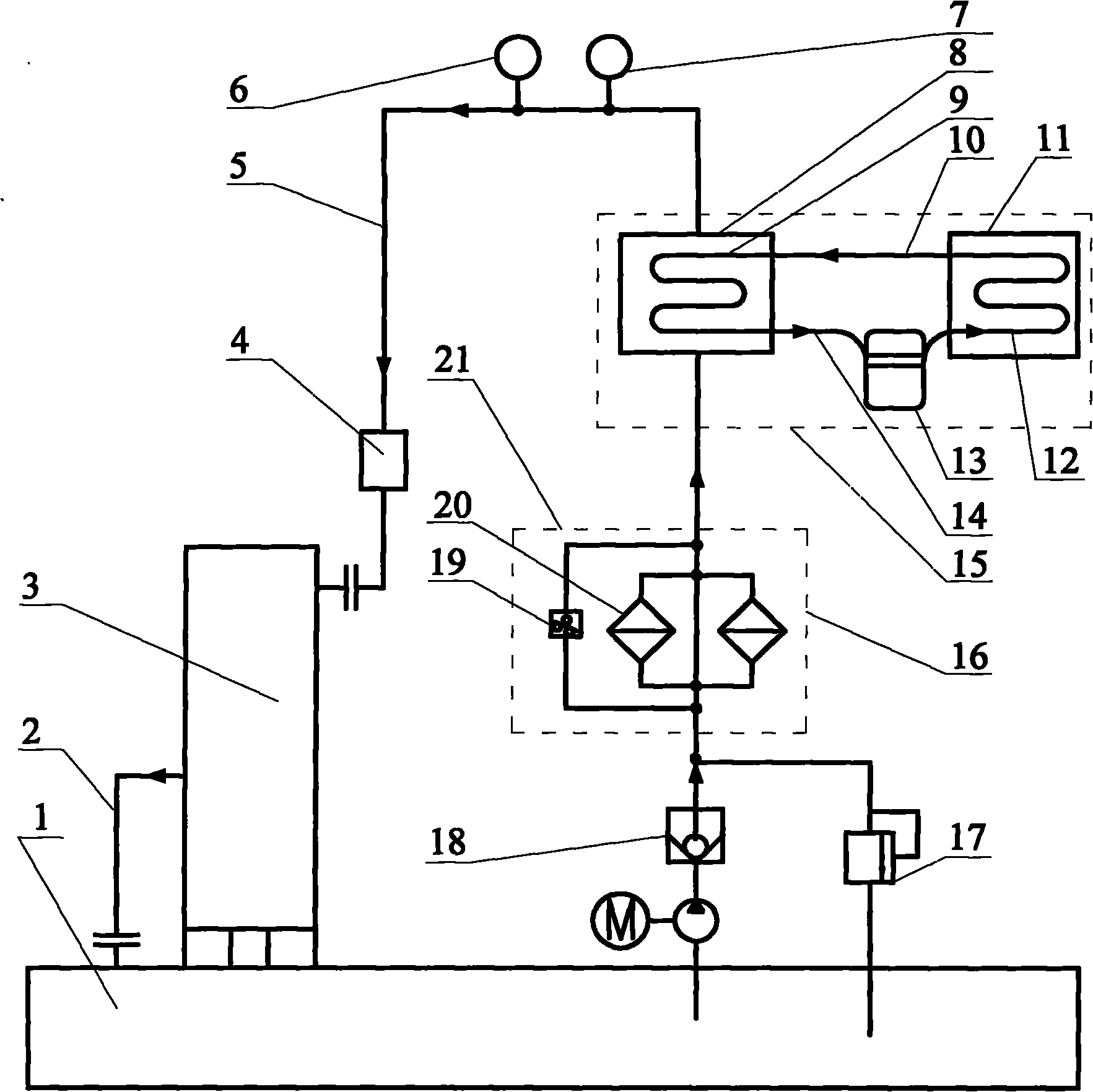

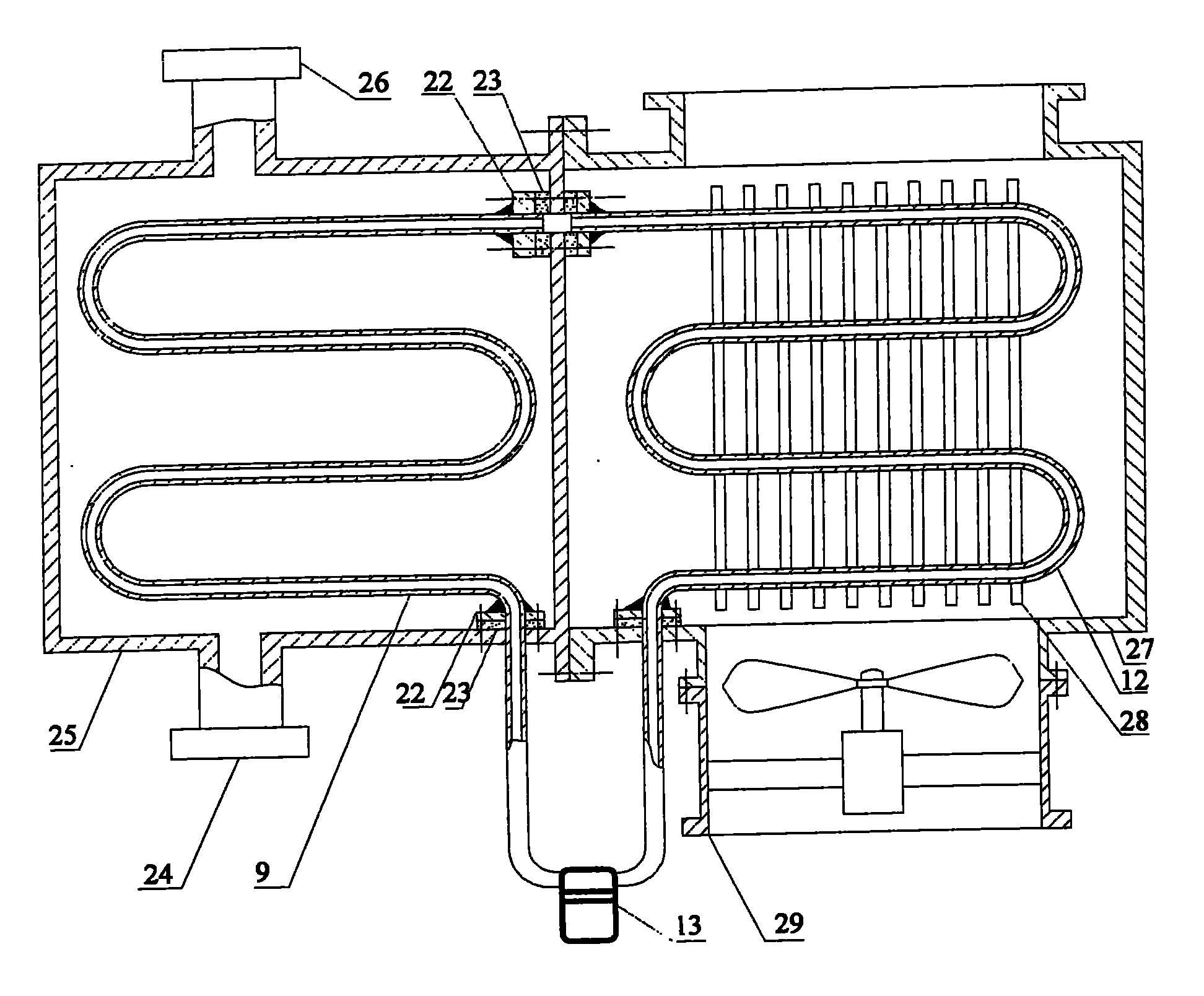

[0012] A single-stage high-speed centrifugal fan lubricating oil cooling device includes a cooler, the cooler includes a heat exchanger, a radiator, and a compressor, the heat exchanger has a heat exchanger box, and an evaporation tube is arranged in the heat exchanger box. The evaporating tube is connected to the heat exchanger box through a pipe joint, and a sealing gasket is set between the pipe joint and the heat exchanger box. The heat exchanger box is provided with an oil inlet and an oil outlet; the radiator has a radiator The box body, the radiator box is equipped with a heat dissipation pipe, the heat dissipation pipe is connected with the radiator box through a pipe joint, a sealing gasket is provided between the pipe joint and the radiator box, a heat sink is provided on the heat dissipation pipe, and a heat sink is provided on one side of the heat dissipation pipe. Cooling fan; the heat exchanger box and the radiator box are respectively provided with connecting fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com