Energy-saving efficient pneumatic motor

An air motor and motor technology, applied in industrial and mining workplaces and in the field of air motors, can solve problems such as low work efficiency and energy waste, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

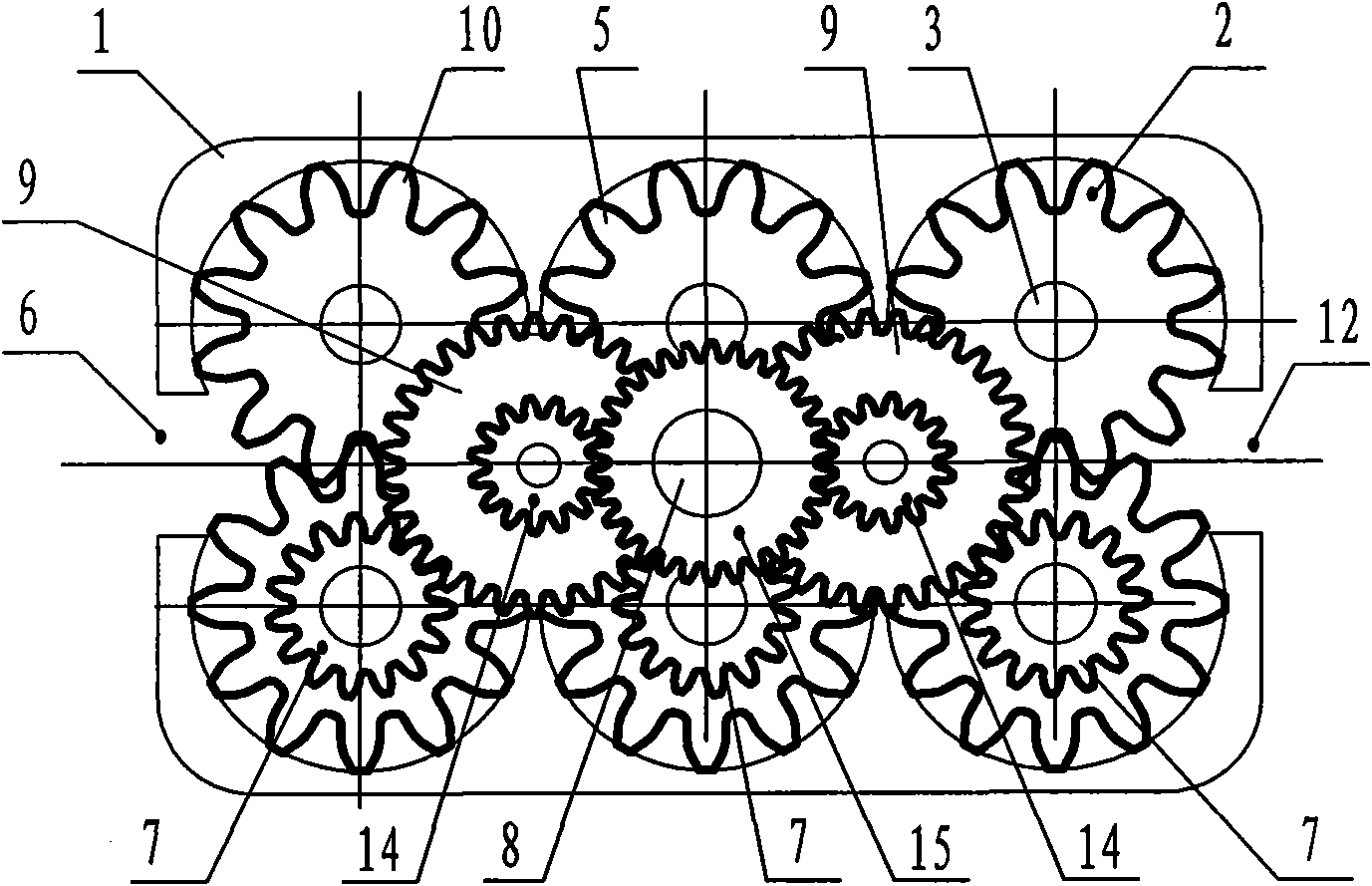

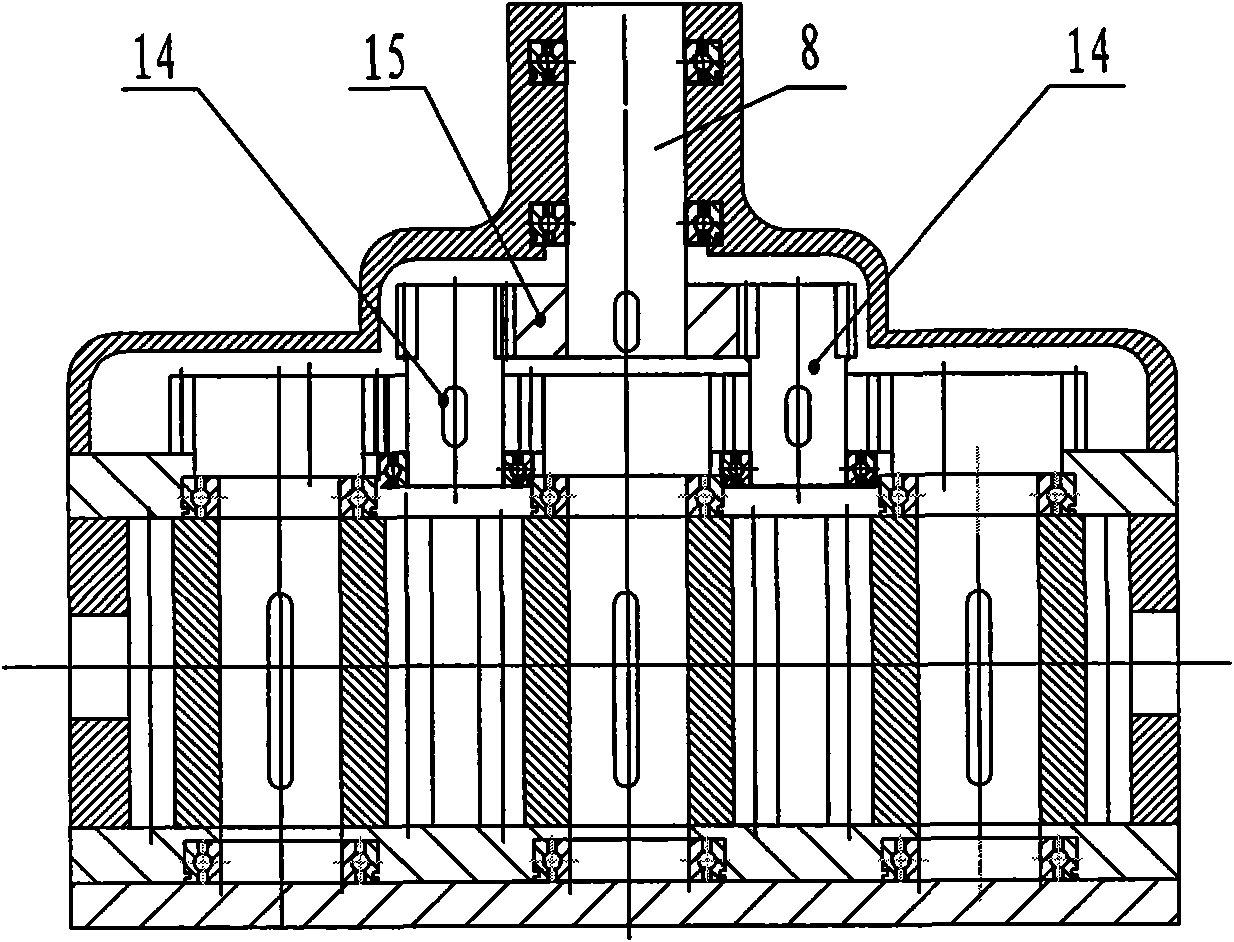

[0018] This example figure 1 , 2 As shown, the main body of the motor casing 1 is a strip shape, and one end of the motor casing 1 is provided with an air inlet 12 , and the other end is provided with an air outlet 6 . Three-stage motor gears are installed in the motor housing 1 , which are respectively a pair of first-stage motor gears 2 , a pair of second-stage motor gears 5 , and a pair of third-stage motor gears 10 . The modules from the first stage motor gear 2 to the third stage motor gear 10 increase step by step. Each motor gear is respectively installed in the motor housing 1 through the shaft 3, and the end of the shaft 3 of a motor gear of each stage of motor gear is fixed with a primary driving gear 7, and each primary primary driving gear 7 is connected to the primary stage. The passive gear 9 meshes, and the primary passive gear 9 is installed on the secondary driving gear shaft 14, the secondary driving gear shaft 14 meshes with the secondary passive gear 15, ...

Embodiment 2

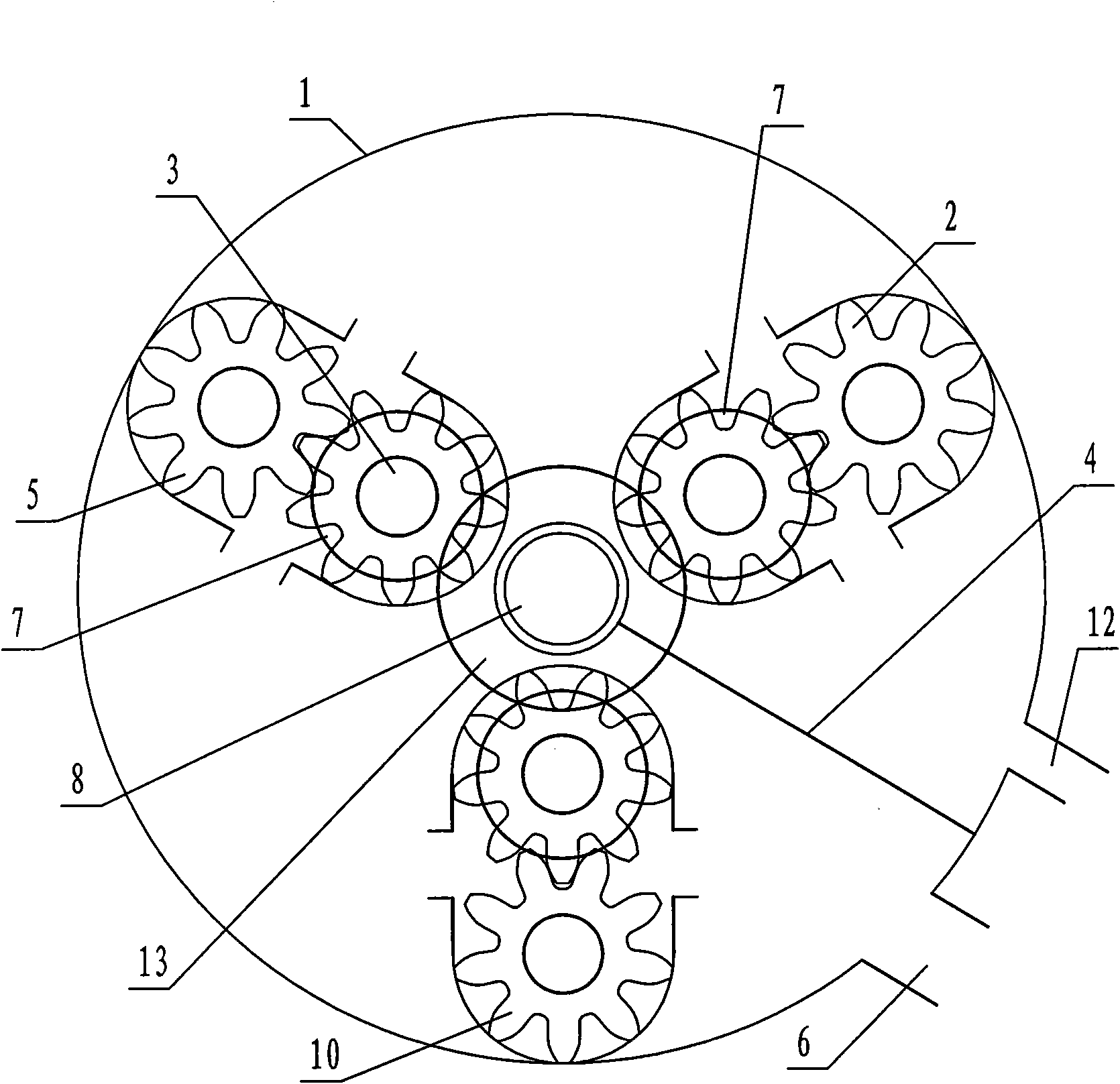

[0020] This example image 3 As shown, the main body of the motor housing 1 is circular, and three-stage motor gears are installed in the motor housing 1, which are respectively a pair of first-stage motor gears 2, a pair of second-stage motor gears 5, and a pair of third-stage motor gears. The modulus of the motor gear 10 increases step by step from the first stage motor gear 2 to the third stage motor gear 10 . Each motor gear is respectively installed in the motor housing 1 through the shaft 3. The center of the motor housing 1 is equipped with an output shaft 8, and each pair of motor gears surrounds the output shaft 8 in stages. Evenly distributed inside. The end of the shaft 3 of each motor gear is provided with a primary driving gear 7, and an output gear 13 is arranged on the output shaft 8. Each primary driving gear 7 meshes with the output gear 13 to form a linkage form. The output power is concentrated on the output shaft 8 for output. The air inlet 12 and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com