Preparation method of high-selectivity absorbing coating of solar vacuum tube

An absorbing coating and high-selectivity technology, which is applied in the field of preparation of selective absorbing coatings for solar vacuum tubes, can solve the problems of limited use, high cost of gold and silver, and shortage of gold and silver, and achieve sputtering rate improvement, low and low temperature emissivity, The effect of low heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

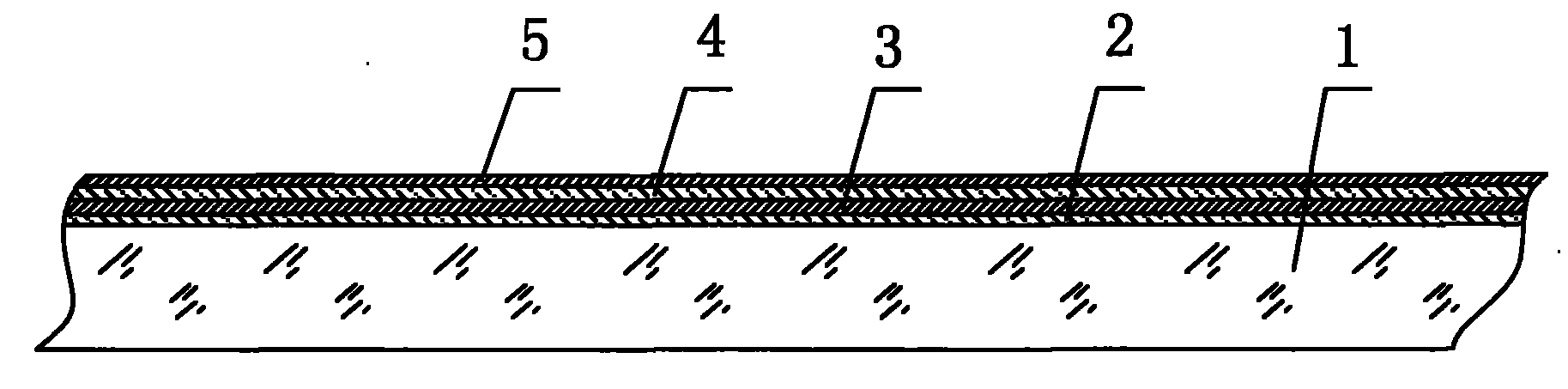

[0018] The method of the present invention is described in detail below with reference to the accompanying drawings.

[0019] The preparation method of the solar vacuum tube highly selective absorption coating of the present invention requires a three-target magnetron sputtering coating machine, three magnetron sputtering cylindrical targets of titanium, stainless steel and aluminum, two sputtering power supplies, one set Composed of high vacuum system and planetary turret system. During the preparation of the film layer, the workpiece is installed on the turret, and the workpiece rotates while revolving. The automatic program controls the operation of the sputtering coating process, and the workpiece is taken out after the process is completed.

[0020] The preparation process is as follows:

[0021] The preparation method of the film belongs to the magnetron reactive sputtering method, the sputtering gas is argon, the reaction gas is high-purity nitrogen and carbon tetraflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com