Process for preparation of compound containing 6A group element using reductant

A technology for compounds and group elements, which is applied in the field of preparing compounds containing 6A group elements using reducing agents, can solve the problems of deterioration of physical properties of the absorption layer, high production costs, and reduced uniformity of the InSe compound layer, and achieves excellent dispersion and coating. performance, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

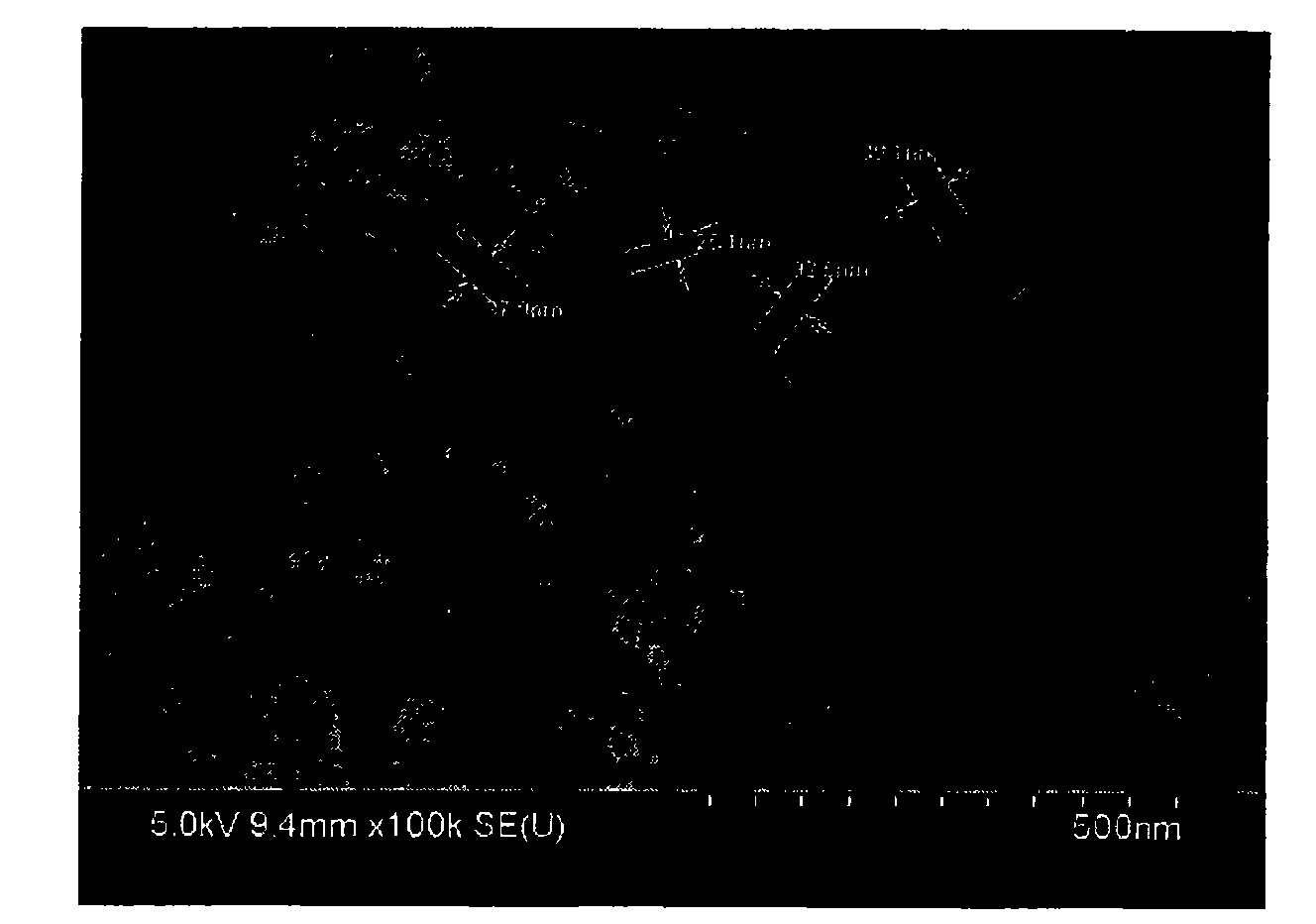

[0054] 10 mmol of indium nitrate aqueous solution and 10 mmol of selenous acid were dissolved in ethylene glycol, mixed together, and heated to 150° C. for reaction. A solution of 10 mmol of copper(II) nitrate and 20 mmol of selenous acid was added to the reaction mixture, followed by the addition of 100 mmol of hydrazine as a reducing agent at room temperature. After reacting for 1 hour, the reaction product was centrifuged and purified to prepare a reaction complex in the form of a core-shell with a size of 50-100 nm, wherein the indium selenide particles were coated with copper selenide.

Embodiment 2

[0056]10 mmol of indium nitrate aqueous solution and 10 mmol of selenous acid were dissolved in 1,4-butanediol, mixed together, and heated to 140° C. for reaction. A solution of 10 mmol of copper(II) sulfide and 30 mmol of selenous acid was added to the reaction mixture, followed by the addition of 100 mmol of hydrazine as a reducing agent at room temperature. After reacting for 3 hours, the reaction product was centrifuged and purified to prepare a reaction complex in the form of a core-shell with a size of 20-100 nm, wherein the indium selenide particles were coated with copper selenide.

Embodiment 3

[0058] 10 mmol of indium nitrate aqueous solution and 15 mmol of selenous acid were dissolved in water, mixed together, and heated to 60°C. 90 mmol of ascorbic acid was added as a reducing agent to the mixture and stirred for 1 hour. A solution of 10 mmol of copper(II) chloride and 20 mmol of selenous acid was added to the reaction mixture, followed by the addition of 100 mmol of hydrazine as another reducing agent. After reacting for 1 hour, the reaction product was centrifuged and purified to prepare a reaction complex in the form of a core-shell with a size of 20-80 nm, wherein the indium selenide particles were coated with copper selenide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com