Voltage-reducing and electricity-saving controller of motor

A power-saving controller, motor technology, applied in AC motor control, motor generator/starter, starter of a single multi-phase induction motor, etc., can solve the problems of low accuracy, narrow power range, waste, etc., Achieve the effect of ensuring accuracy, large power range and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

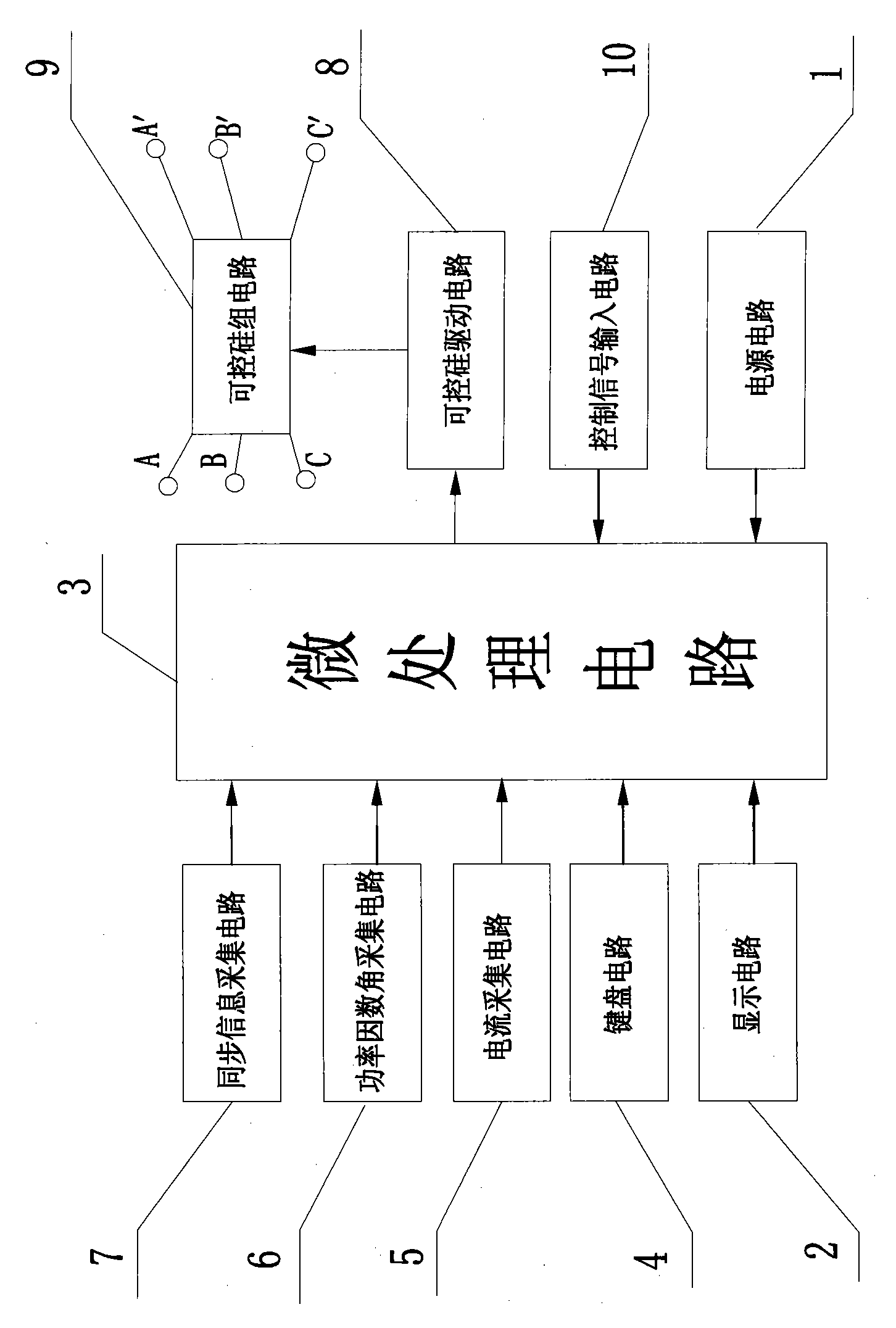

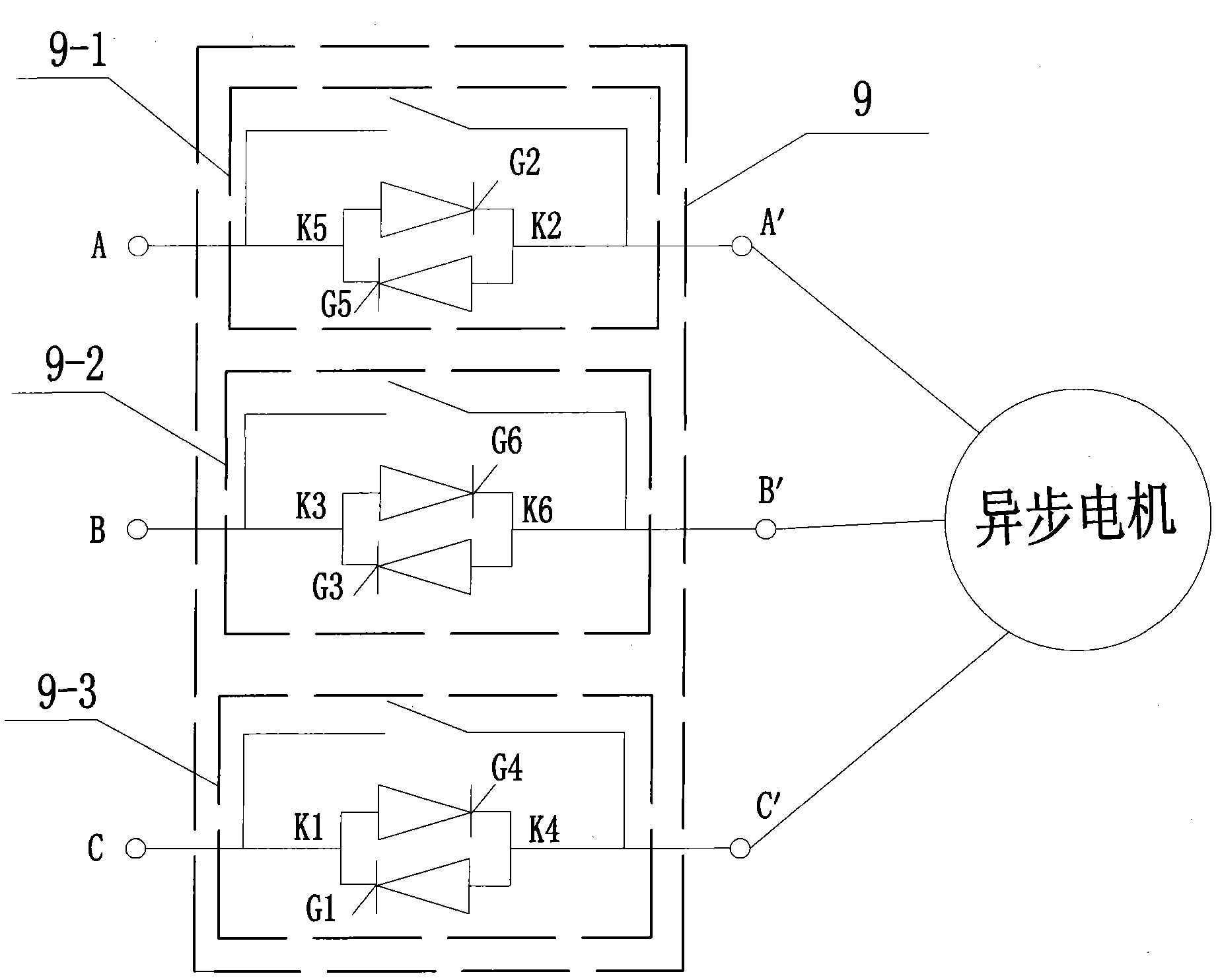

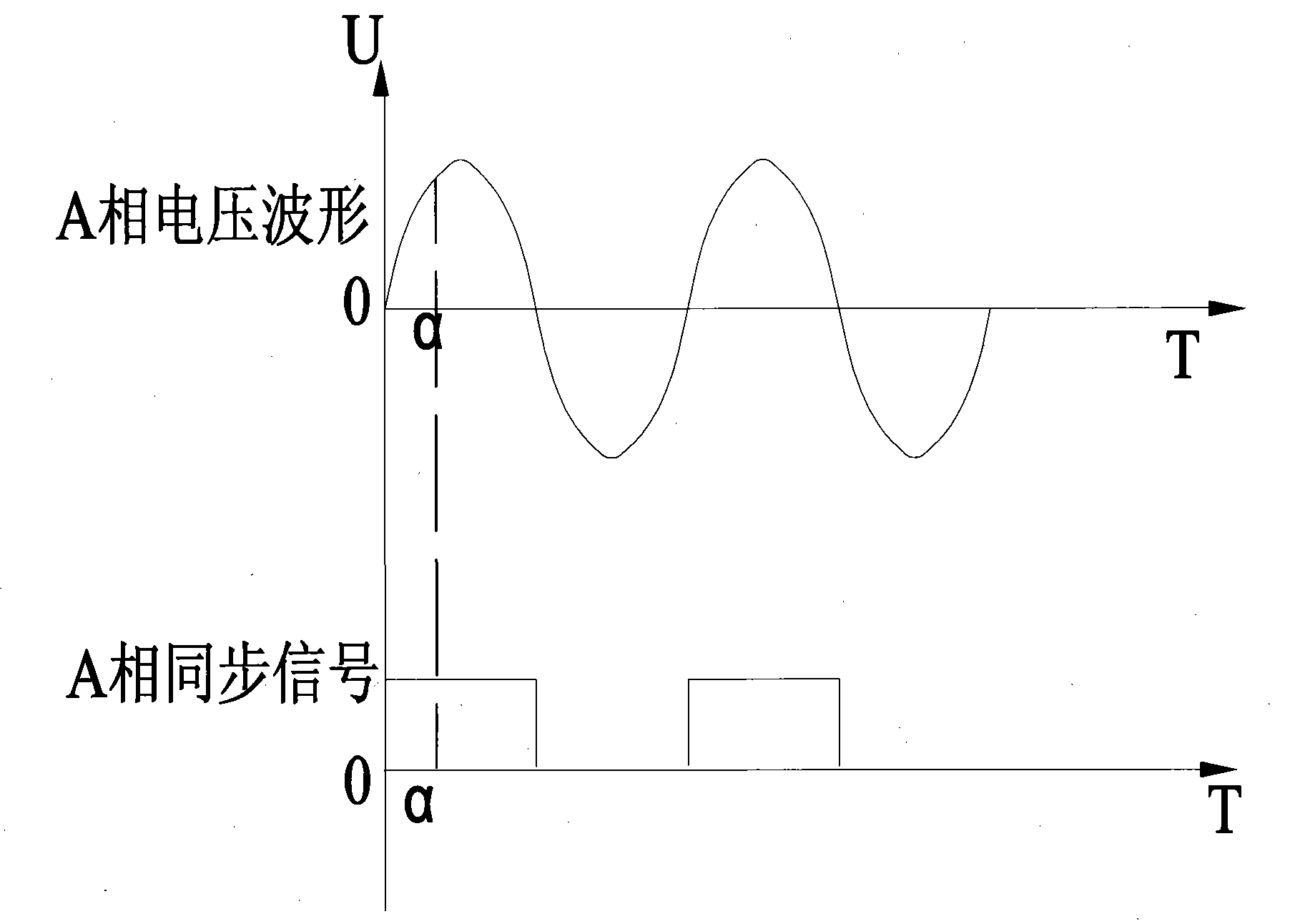

[0024] Such as figure 1 , 2 , 4, 5, 6, 7, and 8, a motor step-down power-saving controller, including a power supply circuit 1, a microprocessor circuit 3 and a power factor angle acquisition circuit 6, a power supply circuit 1, a power factor angle acquisition circuit 6 are all connected with the microprocessor circuit 3, and also include a current acquisition circuit 5, a synchronous information acquisition circuit 7, a thyristor drive circuit 8, a thyristor circuit 9 and a control signal input circuit 10, a current acquisition circuit 5, a synchronous information Acquisition circuit 7, thyristor drive circuit 8 and control signal input circuit 10 are respectively connected with microprocessor circuit 3, and described thyristor circuit 9 includes first thyristor group 9-1, second thyristor Group 9-2 and the third thyristor group 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com