Method for dealing repeated fracture of industrial pipeline caused by thermal stress

A technology for industrial piping and thermal stress, applied in piping systems, blast furnace parts, furnaces, etc., to solve problems such as industrial piping fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solution involved in the present invention is applied to the fracture repair of INBA system pipes of 6#-8# blast furnaces of WISCO.

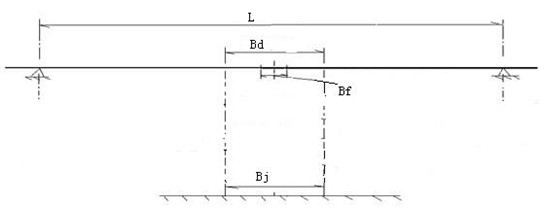

[0069] Such as figure 1 , in the frequent fracture area of the pipeline involved in the case, take the middle point of the straight pipe section with a span of 35 meters between the two fixed supports as the stress release point; take this point as the center mark, extend 1 meter to both sides respectively, as two Jog point marker B d , with an interval of 2 meters; on the floor where the two moving point marks are perpendicular to each other, set the static point reference mark B j . In the interval marked by the moving point, select a pipe section Bf of an appropriate length, cut it off and pull it out. After measurement, the fact that the moving point moves inward to the static point is obtained, and the total amount is an inward extension of 7 mm (named ΔL 1 ). Based on this, it can be confirmed that before this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com