Automatic circular combined hackling machine for hackling and forming strip for flax and combined hackling method thereof

An automatic machine and sliver technology, applied in combing machines, mechanical processing, deburring devices, etc., can solve the problems of backward technology and equipment, low production efficiency and high production cost, reduce the number of workers, improve production efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

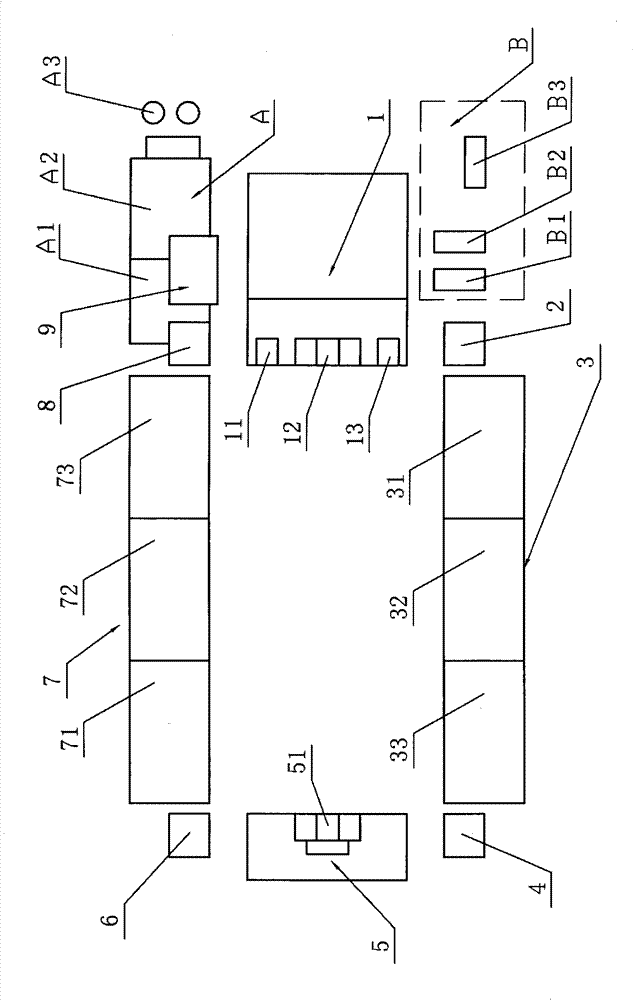

[0047] see figure 2 , is a schematic diagram of the structural layout of a preferred embodiment of the present invention. This embodiment provides a circular automatic combing and combing machine for flax, which has a circular carding production line, a strip production line and a connecting device. The production line includes front automatic machine 1, 1# corner manipulator 2, left carding machine 3, 2# corner manipulator 4, rear automaton 5, 3# corner manipulator 6, right carding machine 7 and 4# corner manipulator 8, the connecting device is Grab manipulator 9, this sliver production line is sliver machine A, specifically, wherein:

[0048] The front automatic machine 1 is provided with the uncapping unit 11 driven by the power system B, the cover unit 12 and the closing unit 13 in sequence on it, and completes the hemp clamping device (not shown in the figure) of the automatic machine 1 before entering respectively. )’s uncapping action, lifting and closing action, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com