Method for preparing ferulic acid by utilizing corn bran hydrolyzed by multifunctional enzyme

A multifunctional enzyme and ferulic acid technology, applied in the field of corn deep processing, can solve the problems of low hydrolysis rate, achieve energy saving, simple process, and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Add 650L of 0.6% NaOH to 100kg of 80-mesh corn husks and soak in dark for 1.5 hours;

[0028] 2) Sterilize the soaked material under high pressure at 0.105PKa at 121°C for 30-60min;

[0029] 3) After cooling the soaking solution to 50°C, adjust the pH to 8, add 20ul of multifunctional enzyme (APE1547) per ml of soaking solution to hydrolyze the ester bond and peptide bond on the cell wall, and put it in a shaker at 50°C for 2 hours. ; Centrifuge at 5500r for 10min;

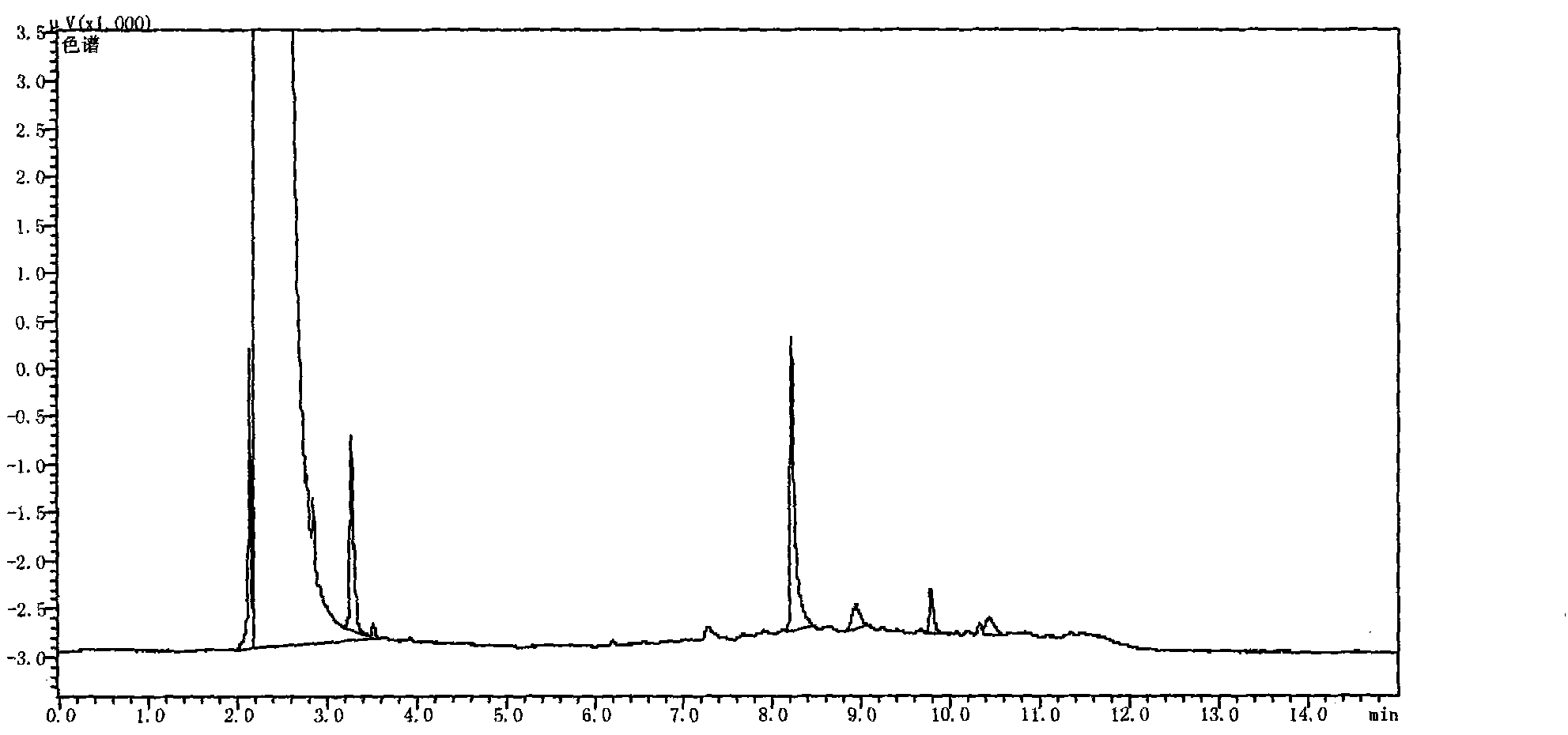

[0030] 4) Take the supernatant, extract it with ethyl acetate, and measure it by gas chromatography. Gas chromatography detection conditions: column temperature 80°C-210°C, heating rate: 15°C / min, stay at 210°C for 3min. The temperature of the sampling chamber is 240°C , The detection chamber temperature is 240°C. The chromatographic column is: DB1701. see results figure 1 .

Embodiment 2

[0032] 1) Add 70 L of 0.6% NaOH to 10 kg of 80-mesh corn husks, and soak for 1.5 hours in the dark;

[0033] 2) Sterilize the soaked material under high pressure at 0.105PKa at 121°C for 30-60min;

[0034] 3) After cooling the soaking solution to 50°C, adjust the pH to 8, add 20ul of multifunctional enzyme (APE1547) per ml of soaking solution to hydrolyze the ester bond and peptide bond on the cell wall, and put it in a shaker at 50°C for 2 hours. ; Centrifuge at 5500r for 10min;

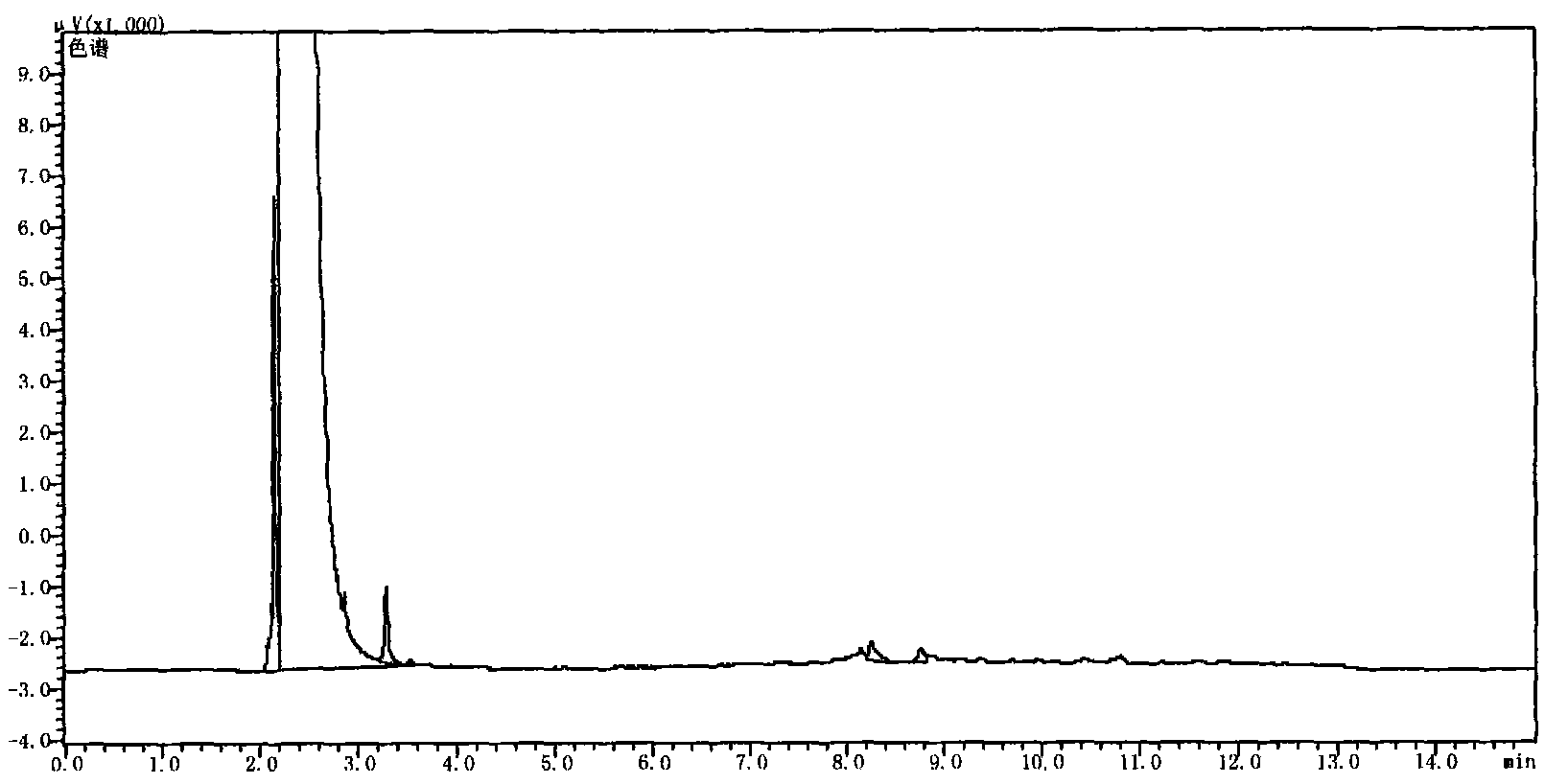

[0035] 4) Take the supernatant, extract it with ethyl acetate, and measure it by gas chromatography. Gas chromatography detection conditions: column temperature 80°C-210°C, heating rate: 15°C / min, stay at 210°C for 3min. The temperature of the sampling chamber is 240°C , The detection chamber temperature is 240°C. The chromatographic column is: DB1701. see results figure 2 .

Embodiment 3

[0037] Purification of ferulic acid

[0038] The supernatant from Step 3 of Example 1, pH = 9.0, was subjected to column chromatography using HPD-600, the ratio of the column material to the supernatant was 1:6 (W / V), sealed and placed at 50°C, 110r / min Complete adsorption in constant temperature shaker, see image 3 ;

[0039] Elution, the eluent is: concentrated hydrochloric acid: water: ethanol 4:35:61, the eluate is concentrated, extracted with an equal volume of ethyl acetate, detected by gas chromatography, see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com