Polypropylene high-filled toughening masterbatch and preparation method thereof

The technology of polypropylene and toughening masterbatch is applied in the field of polypropylene high filling and toughening masterbatch and its manufacturing field, which can solve the problems of waste of resources and low grade, achieve less waste disposal and investment, good environmental protection, and improve related performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further elaborated below through specific examples.

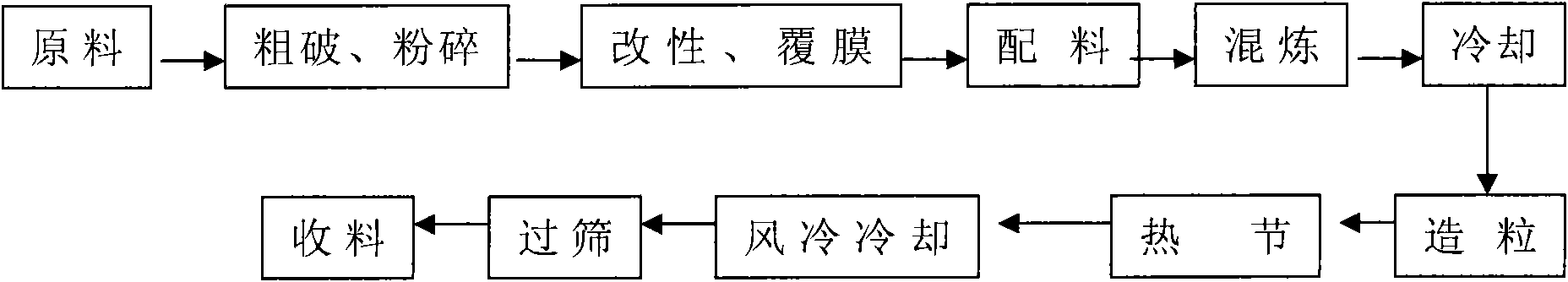

[0018] A kind of preparation method of polypropylene high-filling toughening masterbatch described in the present invention, comprises the following steps:

[0019] 1. After ordinary calcite is processed into superfine heavy calcium carbonate powder, it is activated and modified by a high-pressure air flow machine to obtain a superfine modified powder.

[0020] 2. Ingredients: 150 kg of superfine modified powder, 14-17 kg of polypropylene resin, 3.15-3.85 kg of PP wax, 2.25-2.75 kg of PE wax, 1.8-2.2 kg of monoglyceride, 1.8-2.2 kg of aluminate Kilograms and 4 to 8 kilograms of calcium stearate are used for batching.

[0021] 3. Mixing: The above materials are fully mixed at a high temperature of 140-180°C.

[0022] 4. Pelletizing: After the uniformly mixed material is cooled, put it into the extruder again, and the temperature is controlled between 180 ~ 240 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com