High-power fundamental transverse mode flat plate coupling optical waveguide semiconductor laser structure

A fundamental transverse mode, high-power technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of unfavorable industrialization, high cost, and difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

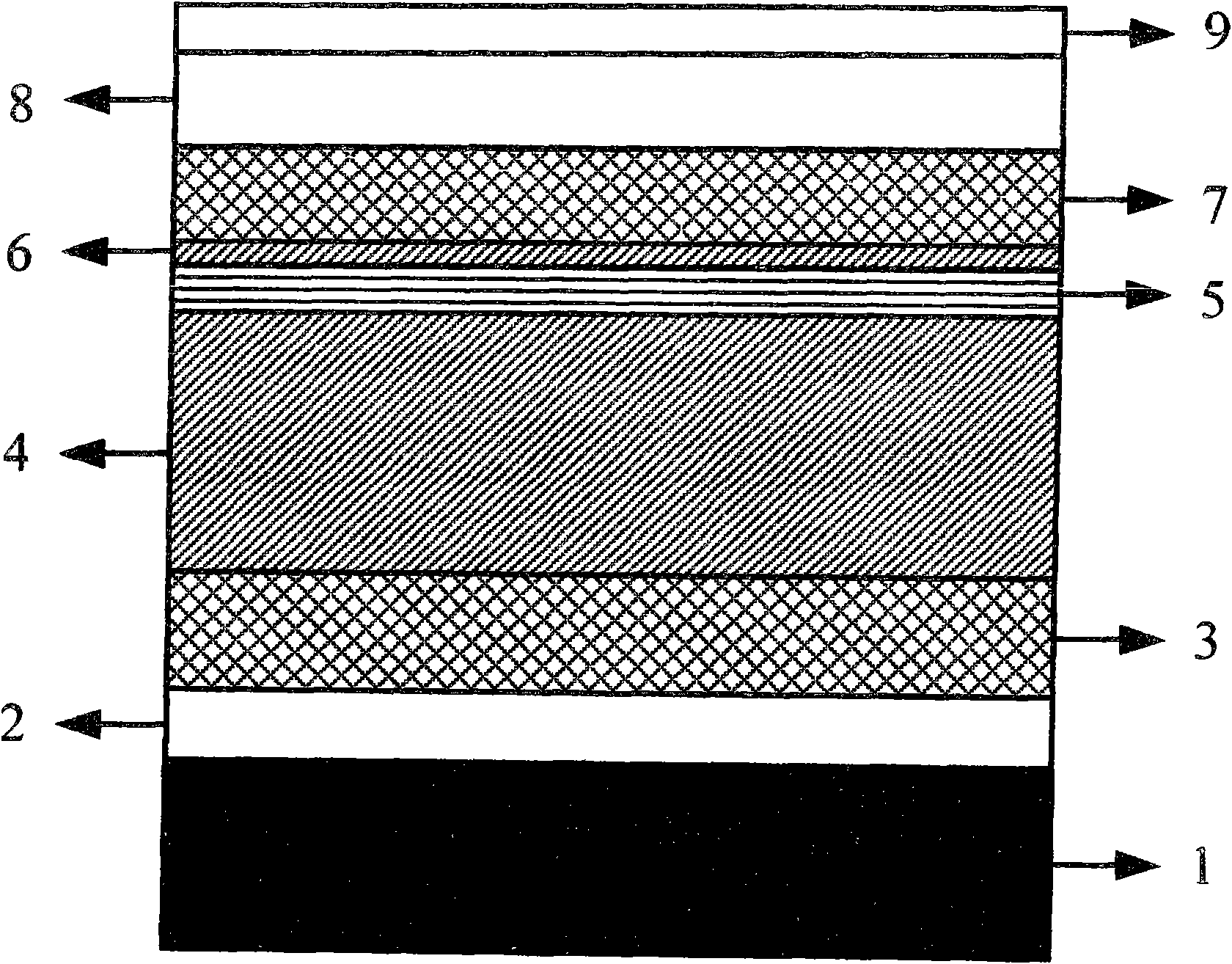

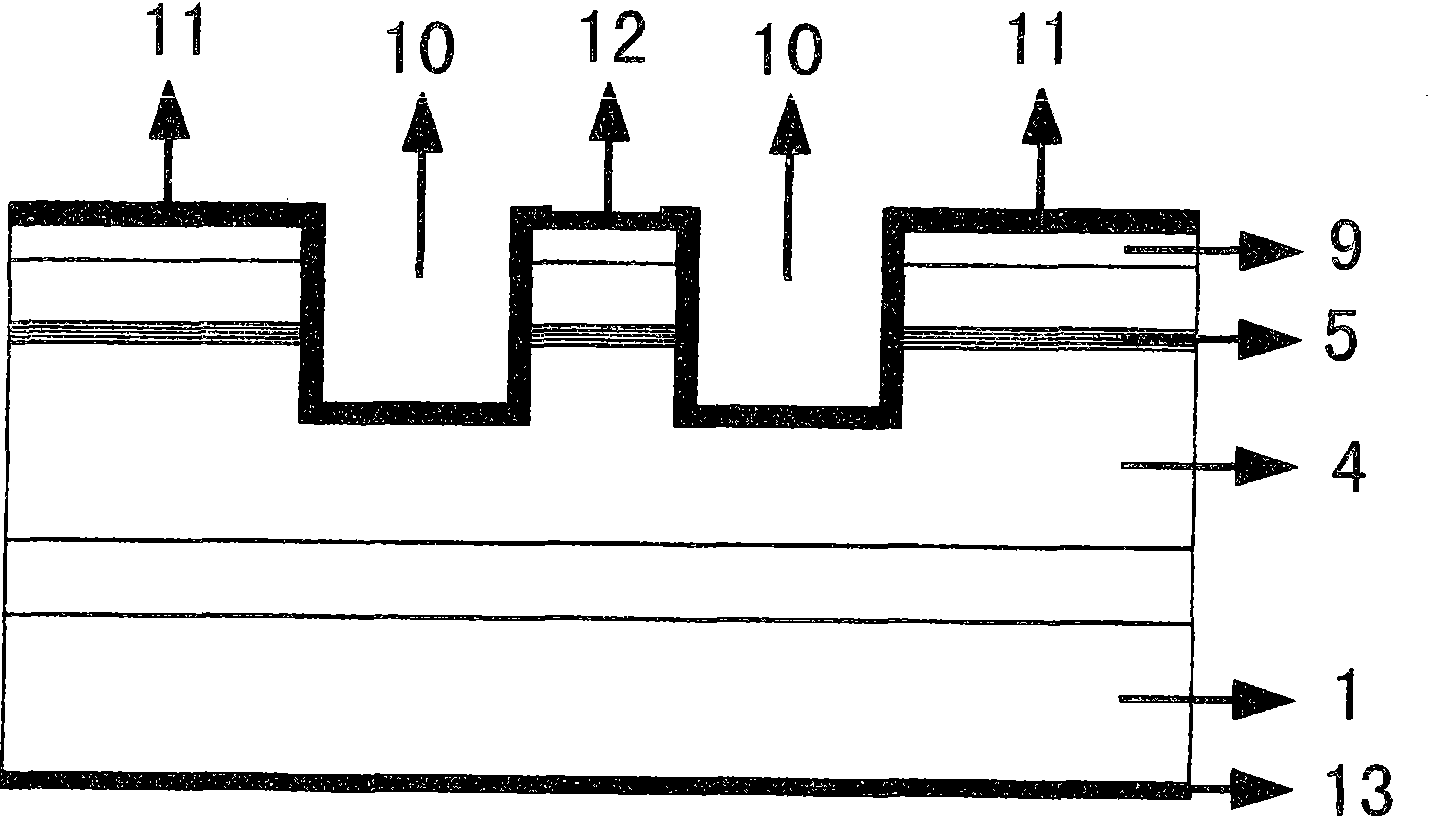

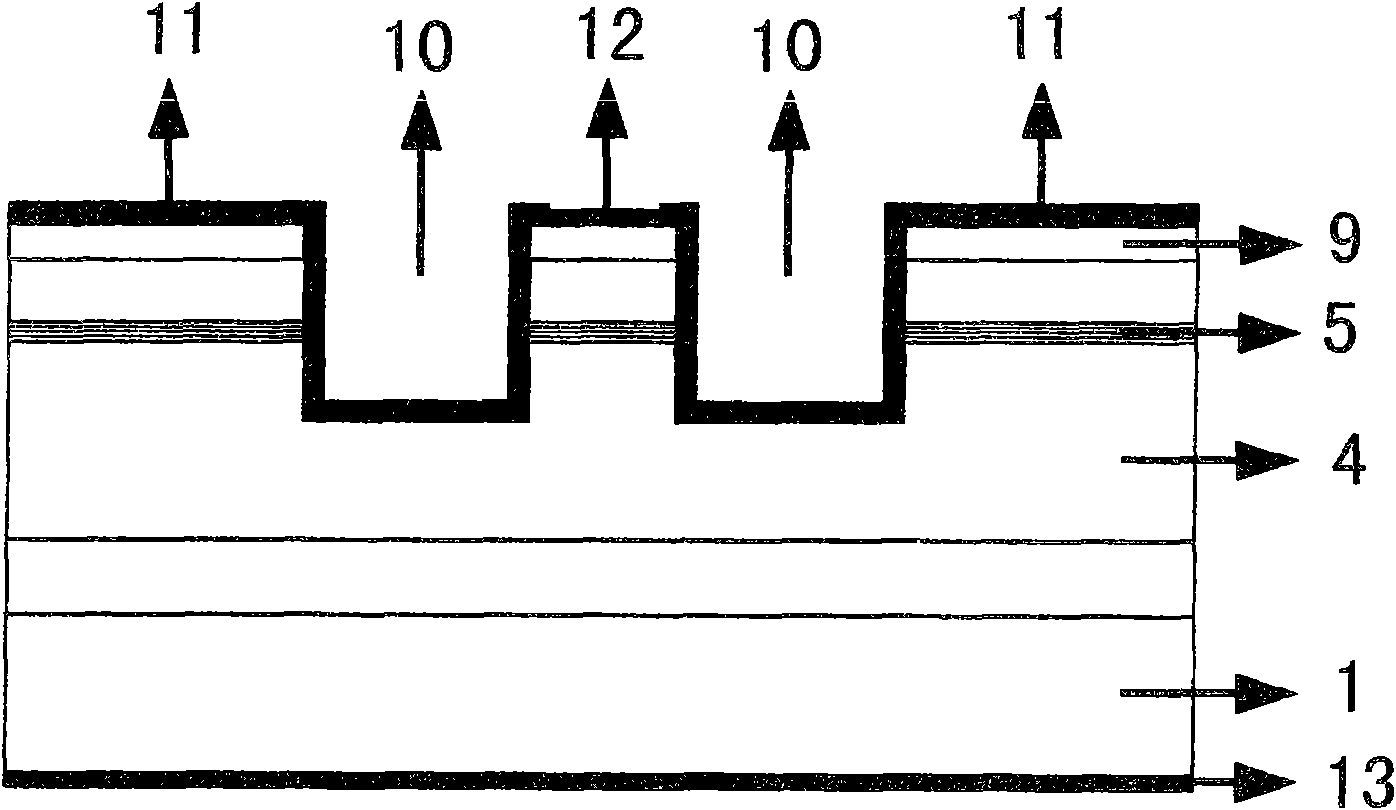

[0031] Combine below figure 1 and figure 2 The details of the structure of a high-power fundamental transverse mode slab-coupled optical waveguide semiconductor laser according to a specific embodiment of the present invention will be described in detail.

[0032] Step 1: Follow the figure 1 The structure shown undergoes epitaxial growth of the material.

[0033] see figure 1 As shown, the structure of a high-power fundamental transverse mode slab-coupled optical waveguide semiconductor laser in this embodiment includes:

[0034] -Substrate 1, the substrate 1 is used to carry out the epitaxial growth of each layer of laser material on it, the substrate 1 is N-type gallium arsenic on the (100) plane, which is beneficial to the injection of electrons and reduces the series connection of substrate materials resistance;

[0035] - buffer layer 2, which is made on the substrate 1 and is an N-type gallium arsenide material, its purpose is to form a high-quality epitaxial surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com