Vickers hardness test system and method

A Vickers hardness and detection system technology, applied in the direction of testing material hardness, image data processing, instruments, etc., can solve the problems of data uncertainty, eye fatigue, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] To facilitate understanding, some terms appearing in the text are explained as follows:

[0015] Corner point: the intersection point when two straight lines form an angle.

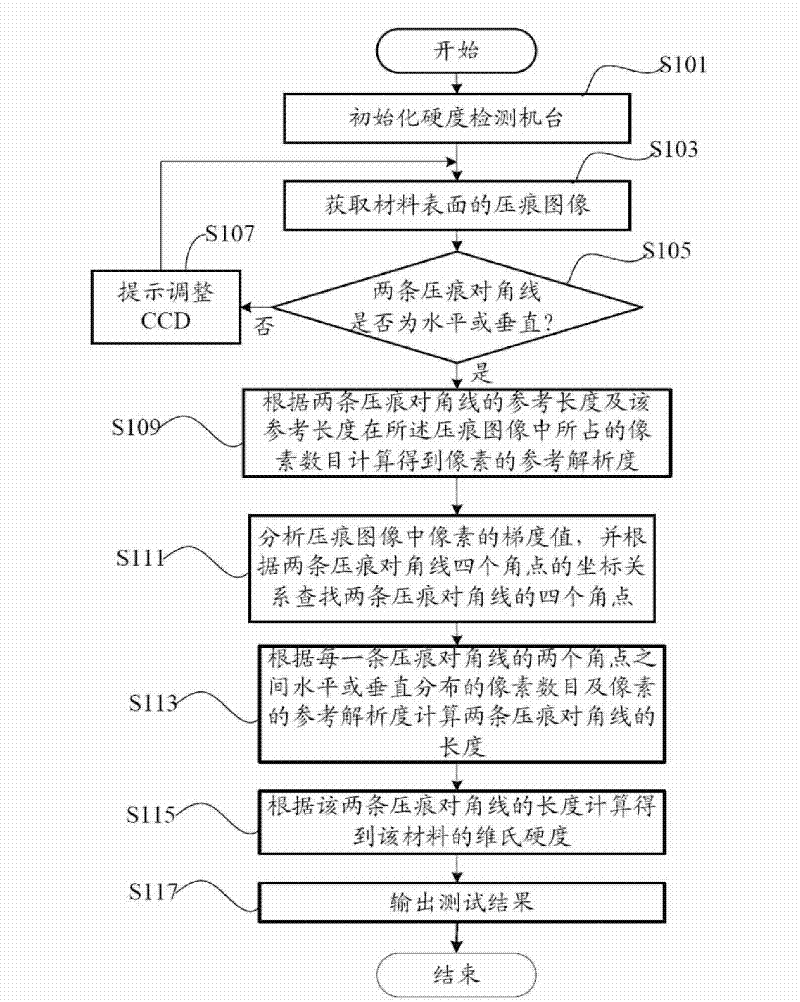

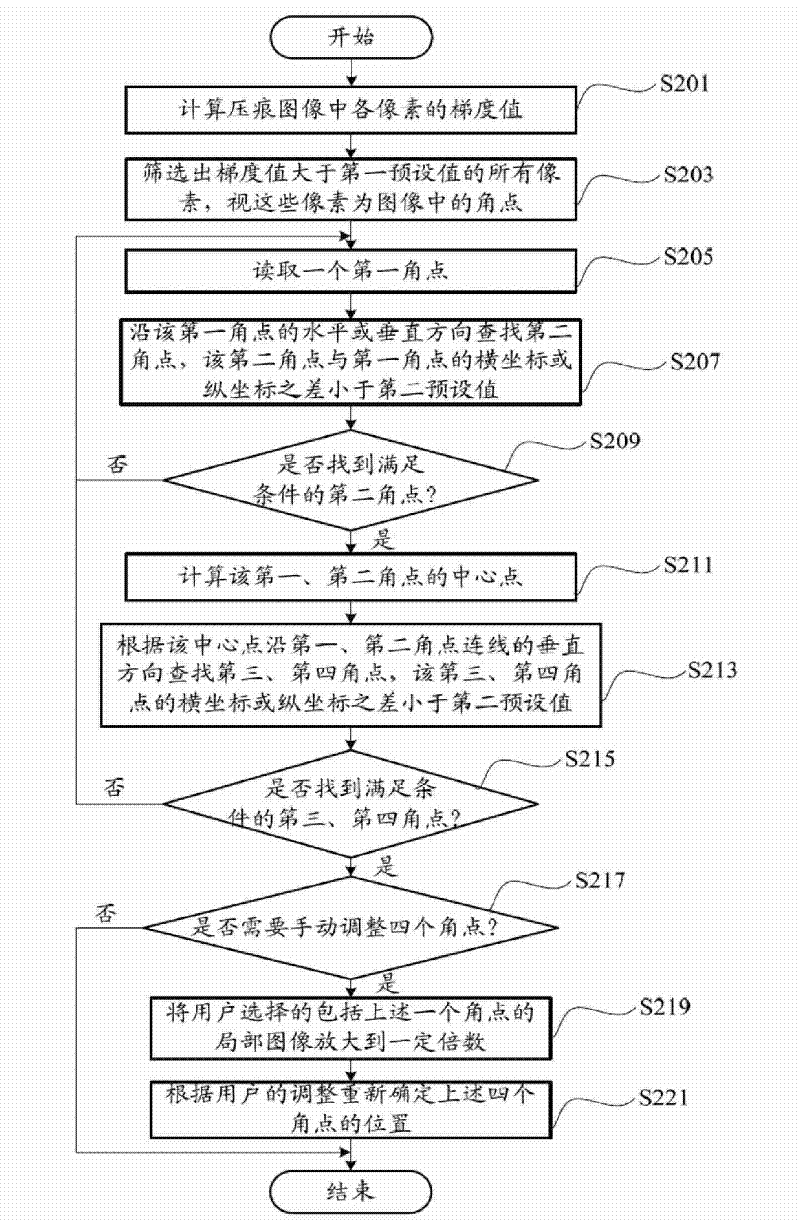

[0016] Such as figure 1 Shown is a functional block diagram of a preferred embodiment of the Vickers hardness testing system of the present invention. The hardness testing machine 10 is connected to a computer 20, and the computer 20 is also connected to a display device 30. The Vickers hardness testing system 40 is installed and running on the computer 20.

[0017] A Charge Coupled Device (CCD) 11 is installed on the Z axis of the hardness testing machine 10, and an industrial optical lens (not shown in the figure) is installed in front of the CCD 11. The hardness testing machine 10 presses a square cone diamond with an angle of 136° between the opposite faces into the surface of the material to be tested, and after maintaining it for a certain period of time, the diamond is removed from the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com