Application of ionic liquid and catalytic oxime removal method thereof

A technology of ionic liquid and catalyst, which is applied in the application of ionic liquid and the field of ionic liquid catalytic deoxime, can solve the problems of difficult product separation, reduced yield of aldehydes and ketones, environmental pollution, etc., and achieves easy separation of products, simple preparation method, The effect of low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

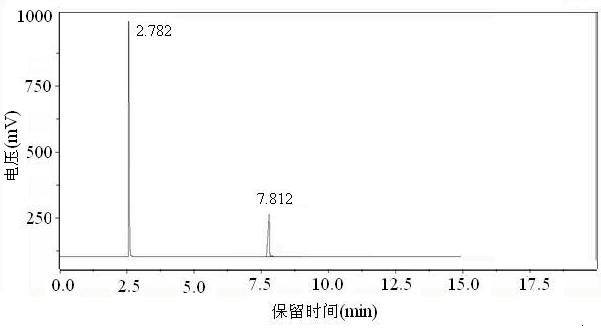

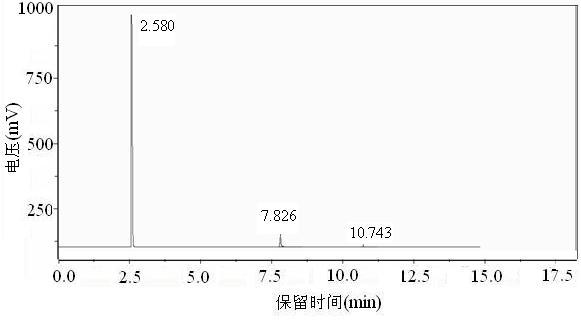

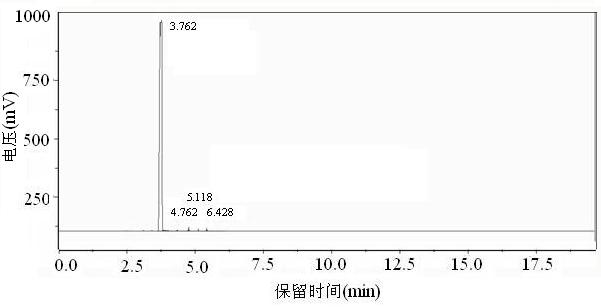

Image

Examples

specific Embodiment approach 1

[0009] Specific Embodiment 1: The application of the ionic liquid in this embodiment is the application of the ionic liquid as a catalyst for the deoxime reaction; the ionic liquid is made of the parent ionic liquid and metal chloride in a molar ratio of 1:1-4 into; wherein the parent ionic liquid is [Rmim]Br, [Rmim]Cl or Et 3 NHCl, R is an alkane group, an aromatic hydrocarbon group or an alkane carboxyl group, mim is methylimidazole, Et is ethyl, metal chloride is FeCl 3 or CuCl 2 .

[0010] The ionic liquid of this embodiment is not only a catalyst for the deoxime reaction, but also a solvent for the system. The catalytic reaction conditions are mild, the reaction temperature is 40°C-100°C, and the reaction time is 0.1h-4h. The reaction time is short. The ionic liquid of this embodiment The liquid is used as a catalyst for the deoxime reaction to make the oxime react into corresponding aldehydes or ketones without by-products, so that the yield of aldehydes or ketones is ...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that the ionic liquid is made from the parent ionic liquid and metal chloride in a molar ratio of 1:1.5-3.5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment 3: The difference between this embodiment and specific embodiments 1 or 2 is that the ionic liquid is made from the parent ionic liquid and metal chloride in a molar ratio of 1:2. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com